Embedded windowing mechanism

A built-in, window-opening technology, which is applied in the direction of power control mechanism, wing leaf control mechanism, mechanical equipment, etc., can solve the problems of hinge resistance window opening, low torque of window opening mechanism, and inability to install windows, etc., to achieve torque increase Larger, wider range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

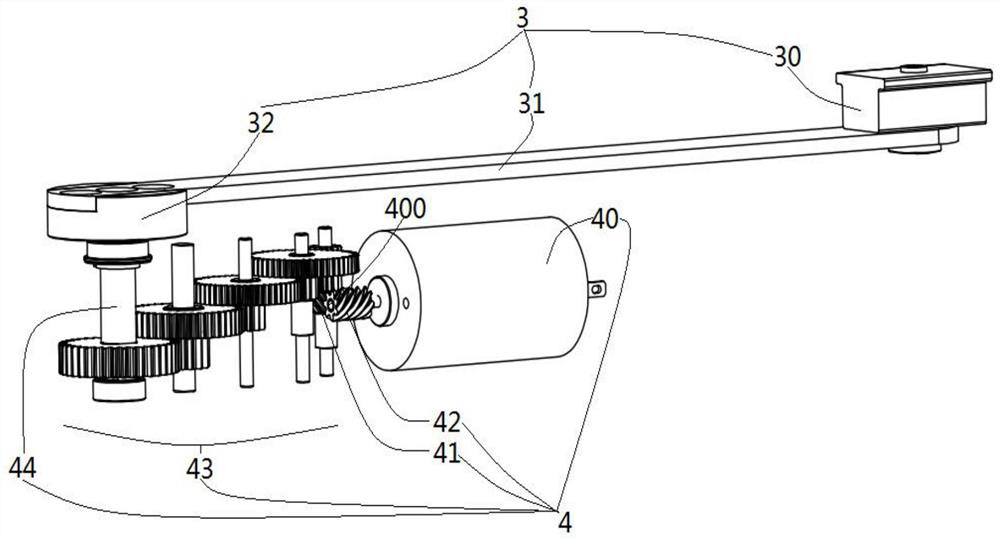

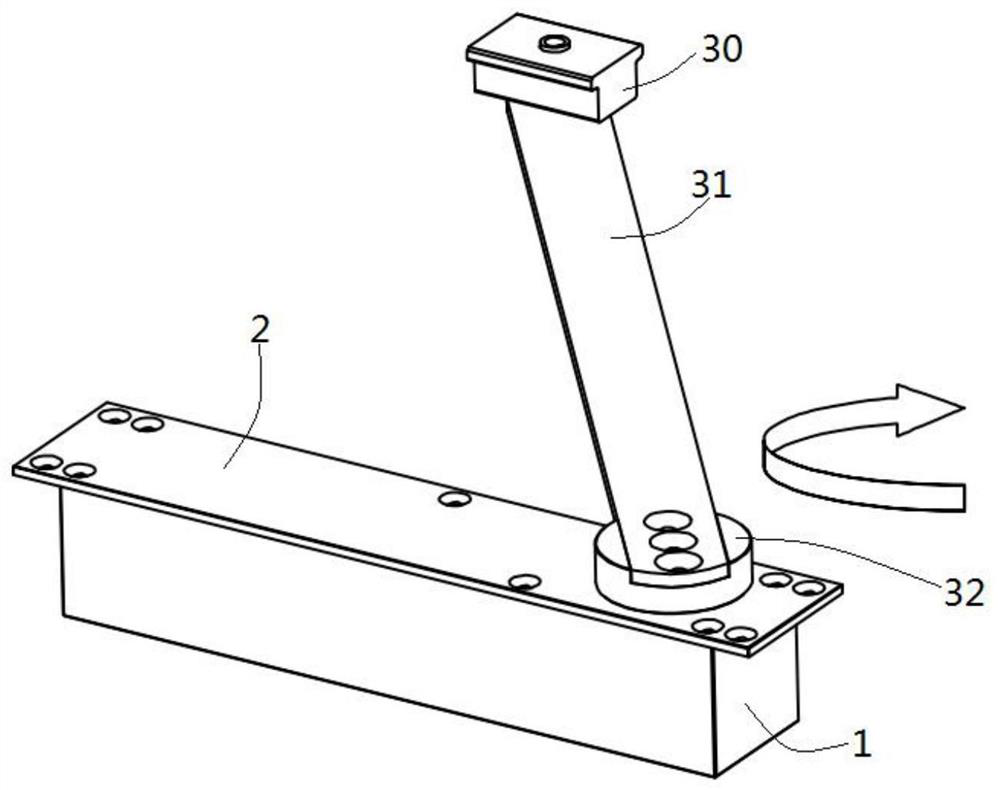

[0028] See attached Figure 1-4 It is a schematic diagram of the overall and partial structure of an embodiment of the present invention. The present invention discloses a built-in window opening mechanism, including: a mounting frame 1, the mounting frame 1 is a hollow rectangular body, and the one with the largest area of the mounting frame 1 A rectangular fixed panel 2 is fixed on the end surface by bolts. The surface of the fixed panel 2 is parallel to the end surface with the largest area of the installation frame 1. The parts connecting the installation frame 1 and the installation frame 1 and the fixed panel 2 are all waterproof. The openings of the openings are all coated with sealant or installed with sealing strips; the actuator 3, the actuator 3 is installed on the end face of the fixed panel 2 away from the mounting frame 1, and the actuator 3 includes a slider 30, a rocker arm 31, a connecting Plate 32, slide block 30 is rotationally connected with one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com