Additional sound insulation surface layer system for floor slabs and construction method of additional sound insulation surface layer system

A floor and surface layer technology, applied in the floor additional sound insulation surface layer system and its construction field, can solve the problems of ceiling sound insulation, floor slab transformation into floating floor slab, floor sound insulation transformation difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

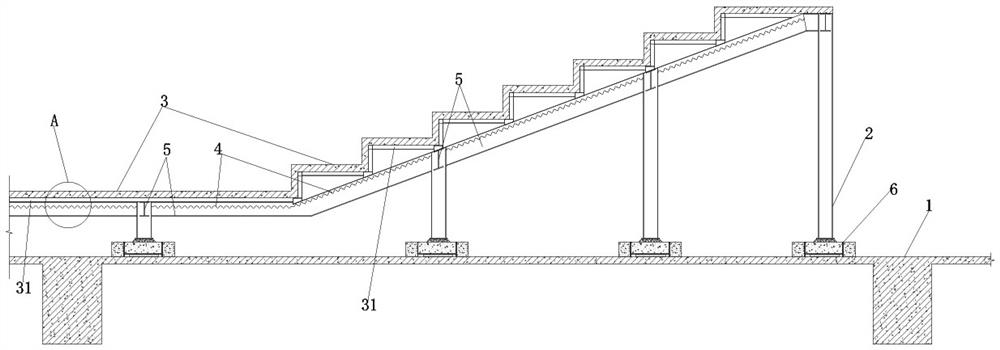

[0032] Such as figure 1 As shown, a floor slab additional sound insulation surface layer system is used for the sound insulation transformation of the floor of the non-ground floor of the building that has been put into use. A resonant sound-absorbing layer 4 is arranged under the panel 3, and the resonant sound-absorbing layer 4 completely separates the original floor 1 from the new floor 3, and forms a closed cavity surrounded by the resonant sound-absorbing layer 4 and the new floor 3; note that here The cavity of the instrument is different from the resonant cavity of the musical instrument. The resonant cavity of the musical instrument converts more mechanical vibration into sound and emits it. The resonant sound-absorbing layer 4 and the cavity here convert the existing sound into mechanical vibration and dissipate it. ;

[0033] There are gaps between the edge of the new floor panel 3 and the edge of the resonant sound-absorbing layer 4 and the walls of the house to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com