High-efficiency water reducing agent and preparation method thereof

A high-efficiency water reducer and initiator technology, applied in the field of water reducer, can solve the problems of low compressive strength and low concrete fluidity retention rate, and achieve good compressive strength, good slump retention, and good lubrication Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

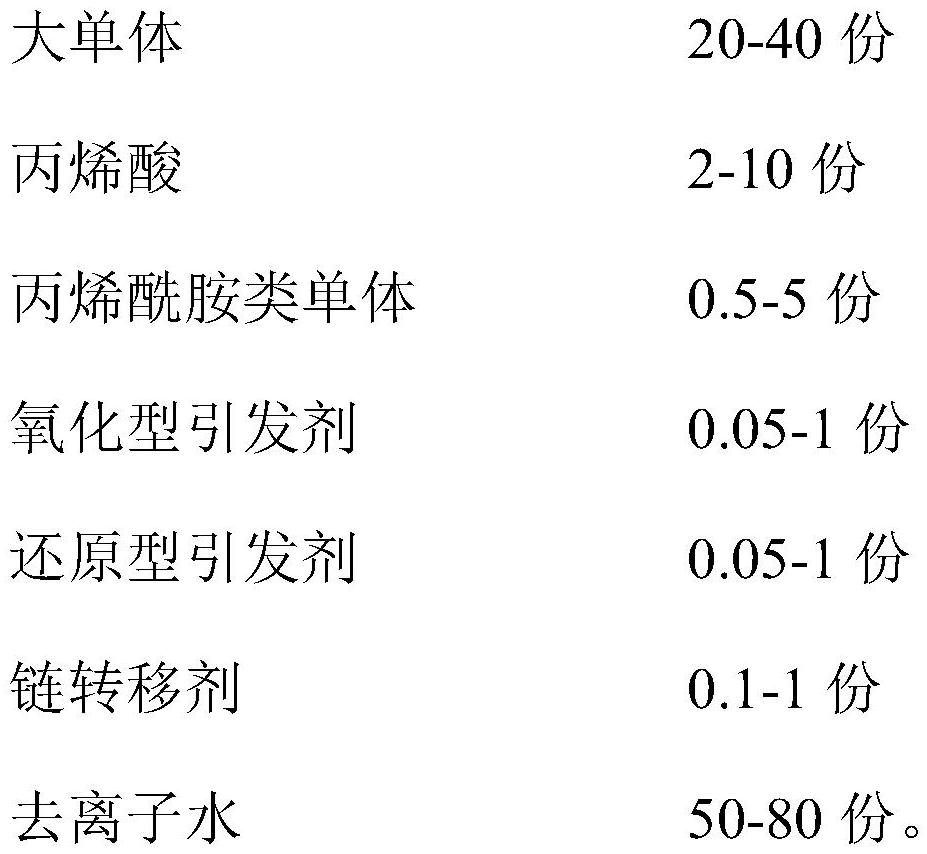

[0025] A high-efficiency water reducer comprising the following components in parts by weight,

[0026]

[0027]

[0028] The preparation method is as follows: S1) inject deionized bottom water into the reaction kettle, add isopentenyl polyoxyethylene ether, and stir for 30 minutes; S2) prepare material A and material B: wherein material A is acrylic acid, acrylamide, 2 -Acrylamide-2-methylpropanesulfonic acid and deionized water, B material is reduced initiator VC, chain transfer agent mercaptoacetic acid and deionized water; S3) Add oxidized initiator hydrogen peroxide in the reaction kettle, and then start dripping Add material A and material B, dropwise adding time is 2.3h, keep moist for 2h after dropping, make up the total weight of deionized water.

Embodiment 2

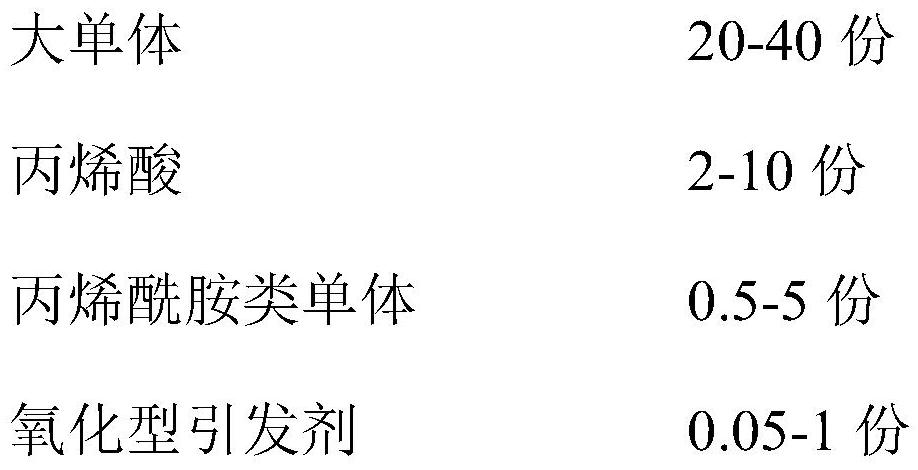

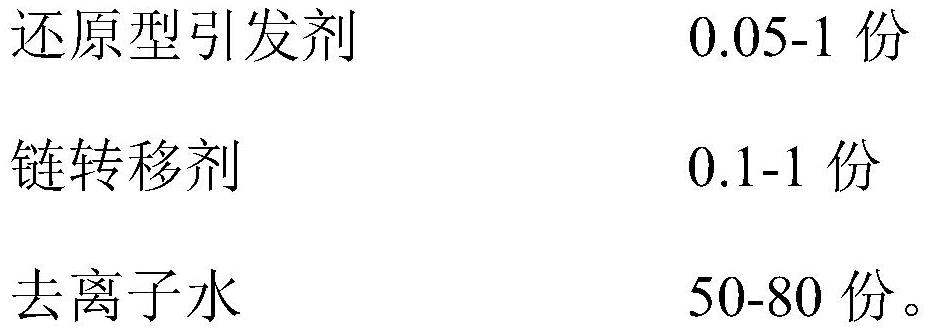

[0030] A high-efficiency water reducer comprising the following components in parts by weight,

[0031]

[0032] The preparation method is as follows: S1) inject deionized bottom water into the reaction kettle, add isopentenyl polyoxyethylene ether, and stir for 30 minutes; S2) prepare material A and material B: wherein material A is acrylic acid, 2-acrylamide -2-Methylpropanesulfonic acid and deionized water, B material is reduced initiator VC, chain transfer agent mercaptoethanol and deionized water; S3) Add oxidized initiator hydrogen peroxide to the reaction kettle, and then start to drop A material And material B, the dropping time is 2 hours, after the dropping is completed, moisturize for 2 hours, and make up the total weight of deionized water.

Embodiment 3

[0034] A high-efficiency water reducer comprising the following components in parts by weight,

[0035]

[0036] The preparation method is as follows: S1) inject deionized bottom water into the reaction kettle, add methallyl polyoxyethylene ether, and stir for 30 minutes; S2) prepare material A and material B: wherein material A is acrylic acid, 2-propylene Amide-2-methylpropanesulfonic acid and deionized water, B material is reduced initiator VC, chain transfer agent sodium hypophosphite and deionized water; S3) Add oxidized initiator hydrogen peroxide in the reaction kettle, and then start dripping Add material A and material B, dropwise adding time is 2.5h, keep moist for 2h after dropping, make up the total weight of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com