Molecular sieve and preparation method thereof

A molecular sieve and quality technology, applied in the direction of molecular sieve catalysts, molecular sieves and base exchange compounds, chemical instruments and methods, etc., can solve the problems of weak catalytic ability of molecular sieves, and achieve excellent hydrothermal aging resistance and good catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

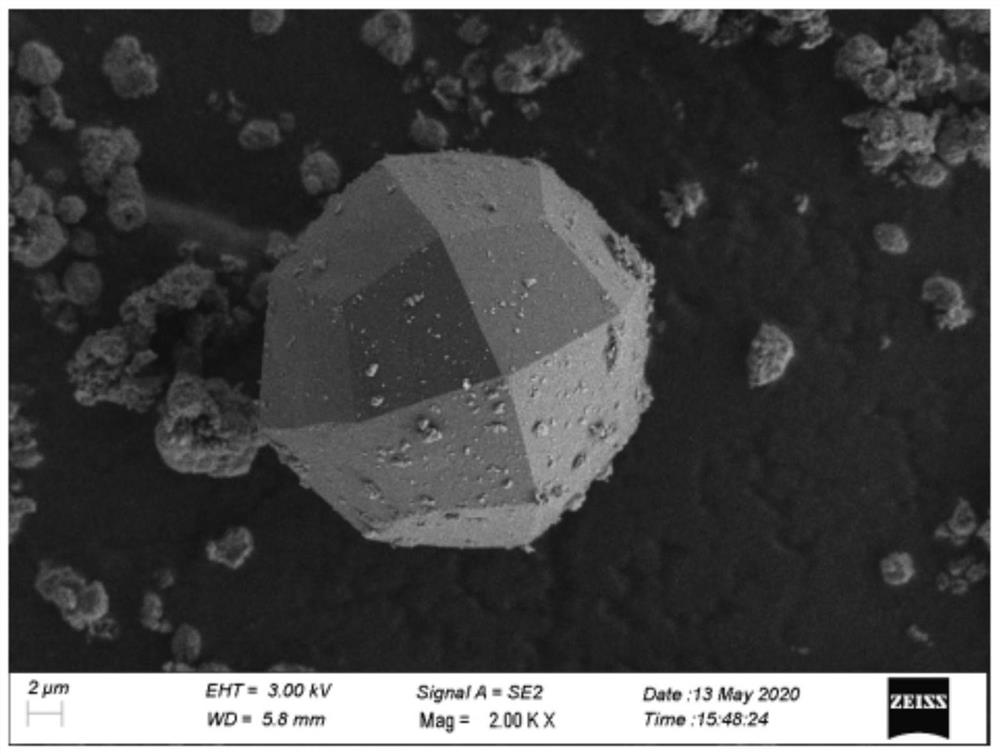

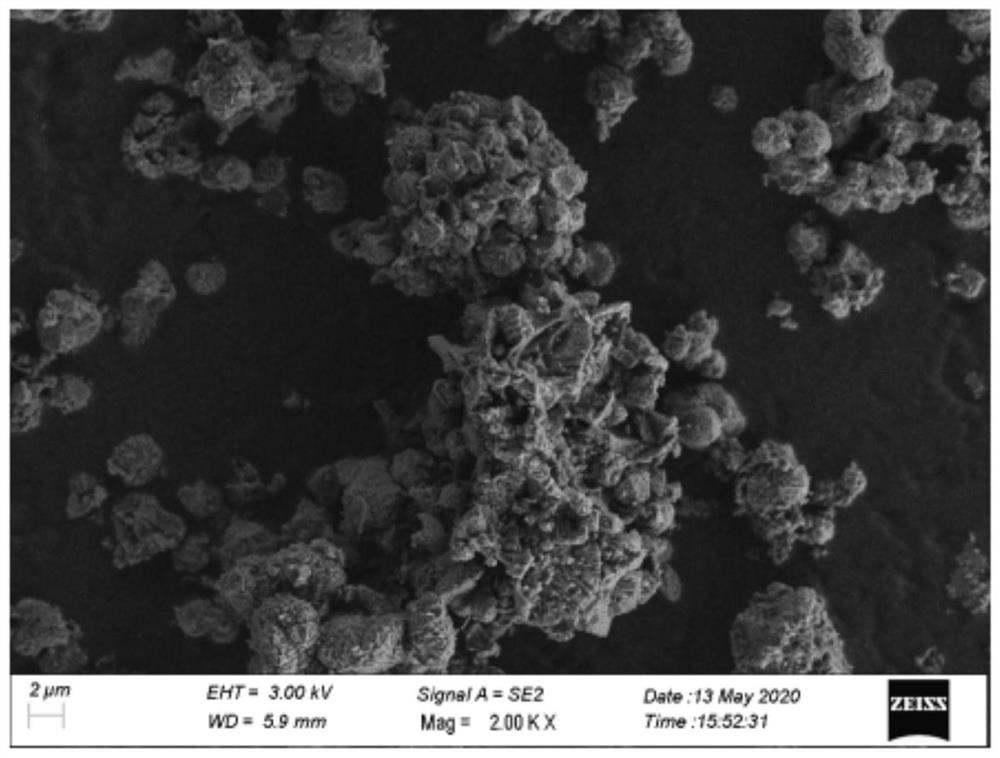

Image

Examples

preparation example Construction

[0055]

[0056] The preparation method of the molecular sieve of the present invention comprises the following steps: (1) the step of the first hydrothermal synthesis reaction; (2) the step of the second hydrothermal synthesis reaction; (3) the step of the third hydrothermal synthesis reaction; (4) The step of roasting. The composition and properties of the resulting molecular sieves are as described above. Detailed description will be given below.

[0057] Steps of the first hydrothermal synthesis reaction

[0058] The template agent, the alkali metal inorganic base, the silicon source, the aluminum source and water form the first mixture, and the first hydrothermal synthesis reaction is carried out.

[0059] The aluminum source of the present invention may be selected from one or more of pseudoboehmite, aluminum hydroxide, aluminum sol or sodium metaaluminate. Preferably, the aluminum source is selected from one or more of aluminum sol or sodium metaaluminate. More p...

Embodiment 1

[0082](1) 28.4g N, N, N-trimethyladamantyl ammonium (TMAda-OH) aqueous solution (concentration is 25wt%), 4.8g sodium hydroxide and 85g water are heated and refluxed at 60 ℃ and mixed uniformly, and then mixed with 32.9 g silica sol (solid content is 20wt%, pH is 3.2, density is 1.2g / cm 3 , with a particle size of 11 nm) and 1.17 g of sodium metaaluminate were stirred and mixed for 2 hours to form a first mixture, which was subjected to the first hydrothermal synthesis reaction at a reaction temperature of 110° C. and a reaction time of 2 days.

[0083] (2) The reaction product of step (1) was cooled to 30°C, then stirred and mixed with 3.43g ammonium nitrate for 8h, then added 8.9g chelated copper glutamic acid and stirred for 3h to form a second mixture, and the second mixture was carried out For the second hydrothermal synthesis reaction, the reaction temperature is 80° C. and the reaction time is 10 h.

[0084] (3) Stir and mix the reaction product obtained in step (2) wi...

Embodiment 2

[0087] (1) 34.4g N, N, N-trimethyladamantyl ammonium (TMAda-OH) aqueous solution (concentration is 25wt%), 6.72g potassium hydroxide and 85g water are heated and refluxed at 50 ℃ and mixed uniformly, and then mixed with 28.5 g silica sol (solid content is 20wt%, pH is 5.6, density is 1.5g / cm 3 , particle size is 11nm) and 7.28g aluminum sol (solid content is 10wt%, pH is 4, viscosity is 43mPa·s, particle size is 10nm) stirring and mixing 3h, forms the first mixture, the first mixture is carried out the first time For the hydrothermal synthesis reaction, the reaction temperature is 130° C., and the reaction time is 3 days.

[0088] (2) Cool the reaction product of step (1) to 25°C, then stir and mix with 4.57g of ammonium nitrate for 8h, then add 8.6g of copper acetate and stir and mix for 3h to form a second mixture, which is subjected to the second water Thermal synthesis reaction, the reaction temperature is 70°C, and the reaction time is 13h.

[0089] (3) Stir and mix the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com