Heavy-load universal wheel

A swivel wheel and wheel frame technology, applied in the field of swivel wheels, can solve the problems of small bearing capacity and eccentricity of the swivel wheel, uneven pressure force of the swivel wheel, and no buffering of the swivel wheel. The effect of large riding load, small steering resistance, and improved lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

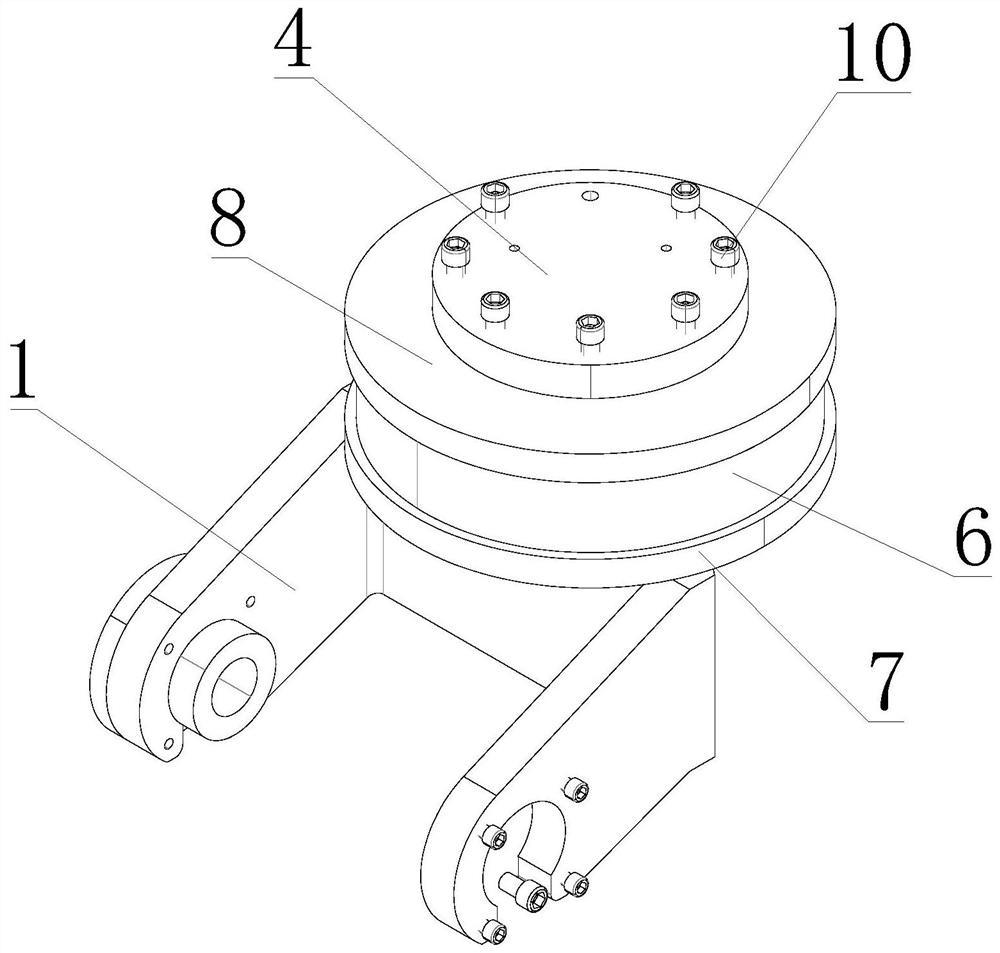

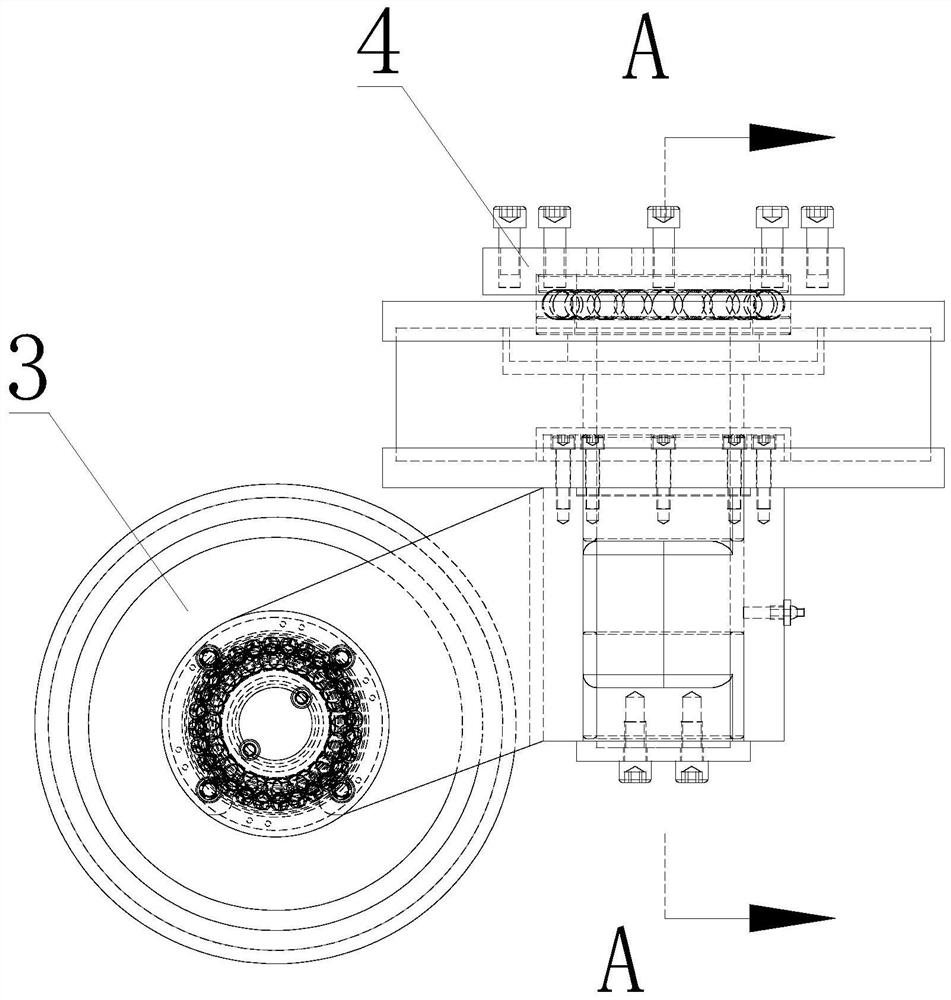

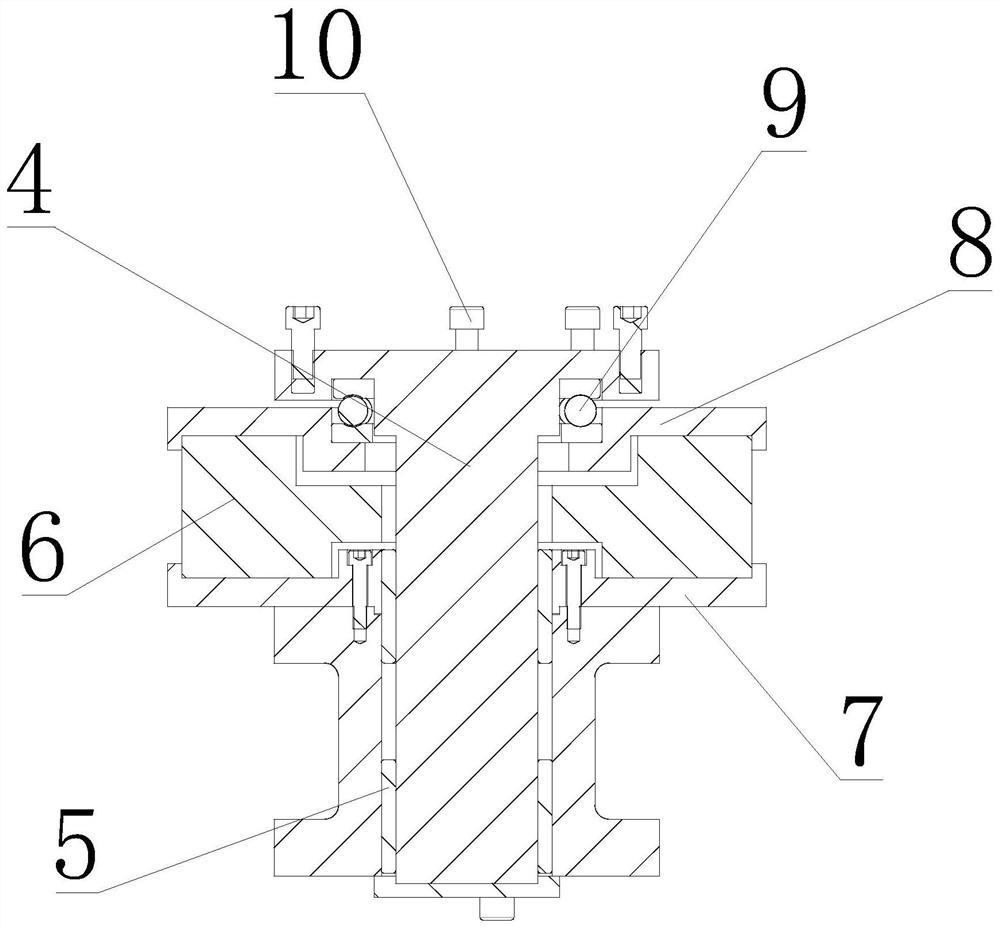

[0022] Such as Figure 1 to Figure 5 As shown, a heavy-duty universal wheel according to the present invention includes a wheel frame 1, an axle 2, a wheel 3, a rotating shaft 4, a cushion 6, a lower baffle 7 of the cushion, an upper baffle 8 of the cushion, and a plane thrust Bearings 9 and mounting bolts 10; the wheel frame 1 is made of high-strength structural steel material, the wheel shaft 2 is horizontally and fixedly installed on the wheel frame 1, and the wheel 3 is rotationally connected with the wheel shaft 2 through the bearing. The rotary shaft 4 is vertically installed on the wheel frame 1, the upper end of the rotary shaft 4 is provided with a cap, the cap at the upper end of the rotary shaft 4 is fixedly installed with the vehicle through the mounting bolt 10, and the inner ring of the plane thrust bearing 9 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com