Reinforcing steel bar groove welding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

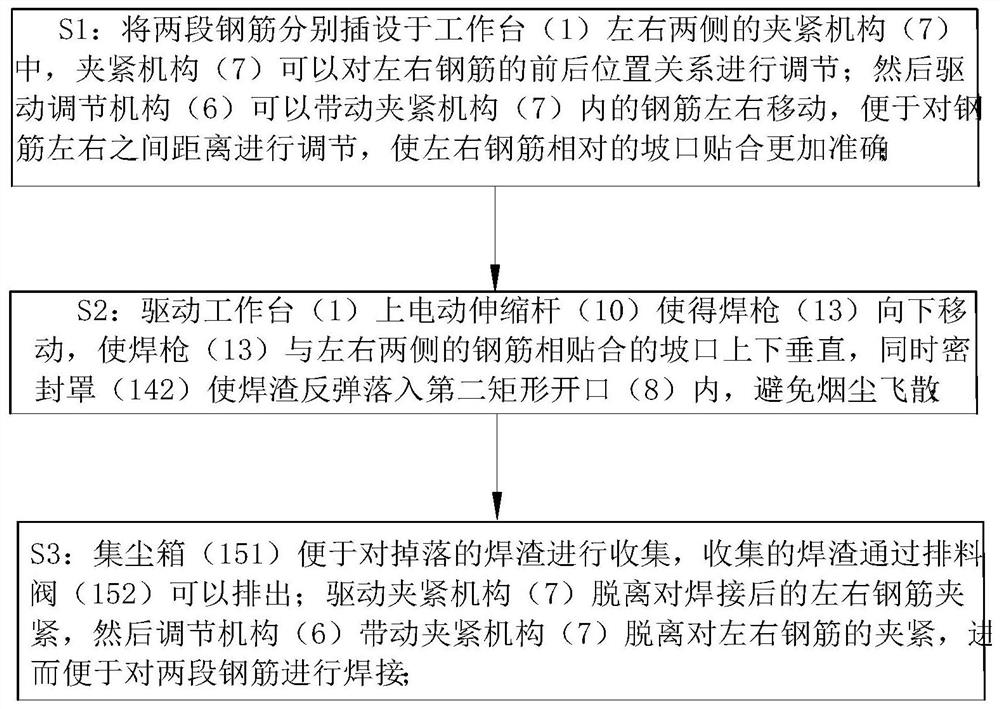

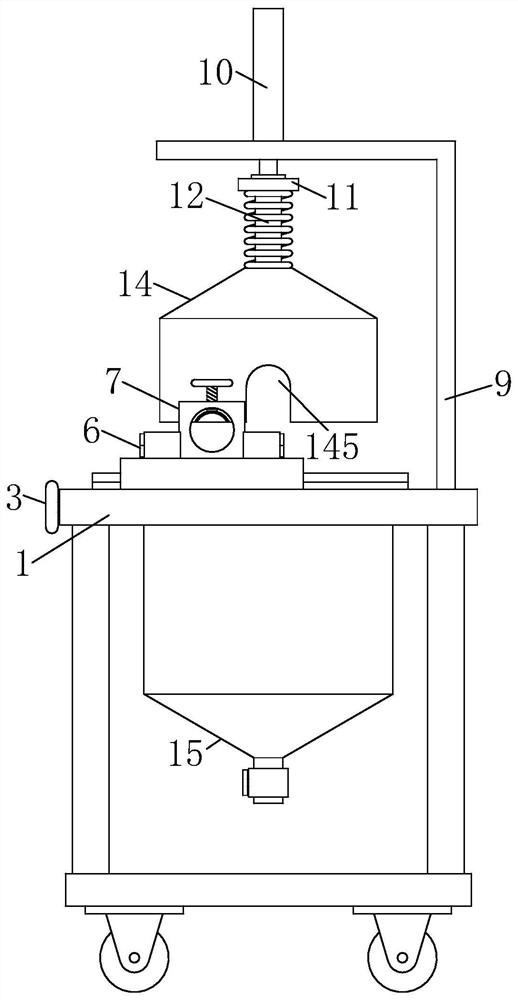

[0030] Such as Figure 1-Figure 7 Shown, a kind of reinforcement groove welding method of the present invention, this method comprises the steps:

[0031] S1: Insert the two sections of steel bars into the clamping mechanism 7 on the left and right sides of the workbench 1 respectively. The clamping mechanism 7 can adjust the front and rear positional relationship of the left and right steel bars; then drive the adjustment mechanism 6 to drive the clamping mechanism 7 The steel bars move left and right, which is convenient to adjust the distance between the left and right steel bars, so that the relative grooves of the left and right steel bars can fit more accurately;

[0032] S2: Drive the electric telescopic rod 10 on the workbench 1 to move t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com