MOF-based MoP-Cu3P transition metal phosphide heterojunction photocatalyst

A transition metal, photocatalyst technology, applied in physical/chemical process catalysts, non-metallic elements, chemical/physical processes, etc., can solve problems such as recombination and low hydrogen evolution efficiency, and achieve the effect of enhancing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) 3.2g of copper acetate monohydrate (Cu 2+ ) and 4.8 g of L-glutamic acid were dissolved in 50 mL of deionized water, stirred at room temperature for 3 h to obtain a clear solution.

[0034] 2) 2.5 g of 1,3,5-benzenetricarboxylic acid (BTC) was dissolved in 50 mL of ethanol, and stirred at room temperature for 3 h to obtain a clear solution.

[0035] 3) Add the clarified solution in step 2) to the clarified solution A in step 1) and stir vigorously for 28 hours;

[0036] 4) The product of step 3) was centrifuged, washed three times with ethanol and once with deionized (DI) water, and dried the precipitate to obtain the MOFNENU-5 derivative.

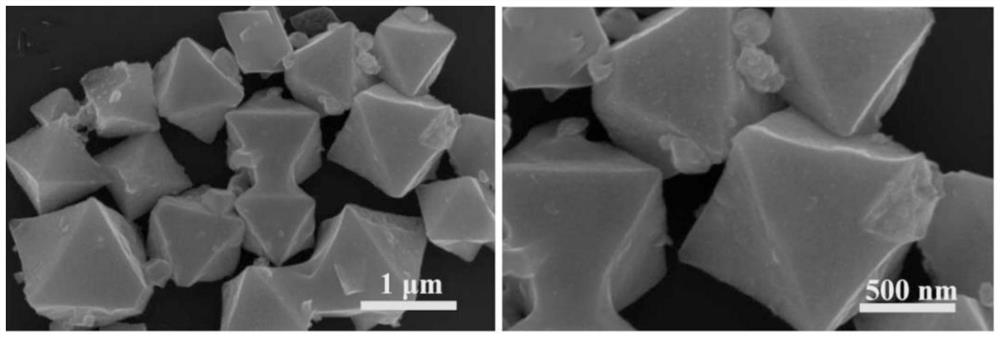

[0037] 5) Step 4) put the product at the gas outlet of the dual-temperature zone tube furnace, put 4.6g of sodium dihydrogen phosphate at the gas inlet, pump the tube furnace pressure to 100Pa, pass Ar gas, and the heating temperature at the gas inlet is 300°C, the heating temperature at the gas outlet is 680°C, and the reactio...

Embodiment 2

[0040] 1) 3.2g of copper acetate monohydrate (Cu 2+ ) and 4.8 g of L-glutamic acid were dissolved in 50 mL of deionized water, stirred at room temperature for 3 h to obtain a clear solution.

[0041] 2) 2.5 g of 1,3,5-benzenetricarboxylic acid (BTC) was dissolved in 50 mL of ethanol, and stirred at room temperature for 3 h to obtain a clear solution.

[0042] 3) Add the clarified solution in step 2) to the clarified solution A in step 1) and stir vigorously for 28 hours;

[0043] 4) The product of step 3) was centrifuged, washed three times with ethanol and once with deionized (DI) water, and dried the precipitate to obtain the MOFNENU-5 derivative.

[0044] 5) Step 4) The product is placed at the gas outlet of the dual temperature zone tube furnace, 4.6g of sodium dihydrogen phosphate is placed at the intake end, the pressure of the tube furnace is pumped to 100Pa, and Ar gas is passed through the dual temperature zone tube furnace The temperature at the inlet end is raised...

Embodiment 3

[0047] 1) 3.2g of phosphomolybdic acid hydrate (PMo12), 3.2g of copper acetate monohydrate (Cu 2+ ) and 4.8 g of L-glutamic acid were dissolved in 50 mL of deionized water and 4.8 g of L-glutamic acid was dissolved in 50 mL of deionized water, and stirred at room temperature for 3 h to obtain a clear solution.

[0048] 2) 2.5 g of 1,3,5-benzenetricarboxylic acid (BTC) was dissolved in 50 mL of ethanol, and stirred at room temperature for 3 h to obtain a clear solution.

[0049] 3) Add the clarified solution in step 2) to the clarified solution A in step 1) and stir vigorously for 28 hours;

[0050] 4) The product of step 3) was centrifuged, washed three times with ethanol and once with deionized (DI) water, and dried the precipitate to obtain the MOF NENU-5 derivative.

[0051] 5) The product of step 4) was ground and mixed with 4.6 g of sodium dihydrogen phosphate, synthesized at a high temperature under 100 Pa pressure, and the temperature at the inlet end of the dual-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com