Pier beam buffer structure and anti-seismic bridge

A structure, pier and beam technology, applied in the field of pier beam buffer structure and seismic bridges, can solve problems such as large earthquake response and damage to bridge structures, and achieve the effects of reducing lateral displacement, strengthening bridge structures, and improving lateral seismic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

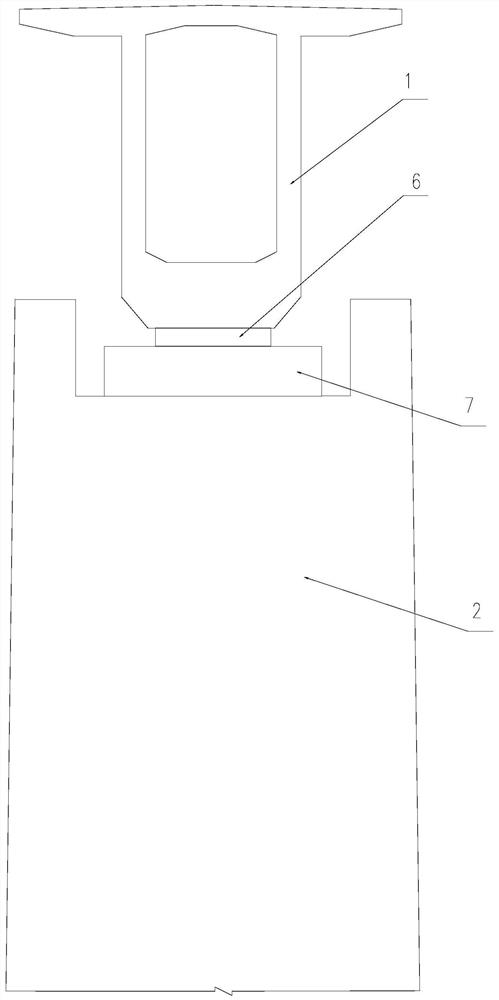

[0052] Such as figure 2 As shown, a pier-beam buffer structure includes a bridge pier 2 and a main girder 1, the main girder 1 is a box girder, and the main girder 1 includes a top plate 11, a web 12 and a bottom plate 13, and the top plate 11 and the The bottom plate 13 is relatively arranged, the web 12 is arranged between the top plate 11 and the bottom plate 13, the top of the pier 2 is provided with an installation groove, and the main girder 1 is located in the installation groove. Specifically, the The top surface of the pier 2 is flush with the web 12, so that the web 12 is completely contained in the pier 2, so that an anti-shock cushion is provided between the main girder 1 and the pier 2 in the transverse direction The block 21 utilizes the buffering and anti-collision effect of the shockproof cushion block 21 to reduce the mutual collision and extrusion between the main girder 1 and the bridge pier 2 under the earthquake force, and consume the collision energy. R...

Embodiment 2

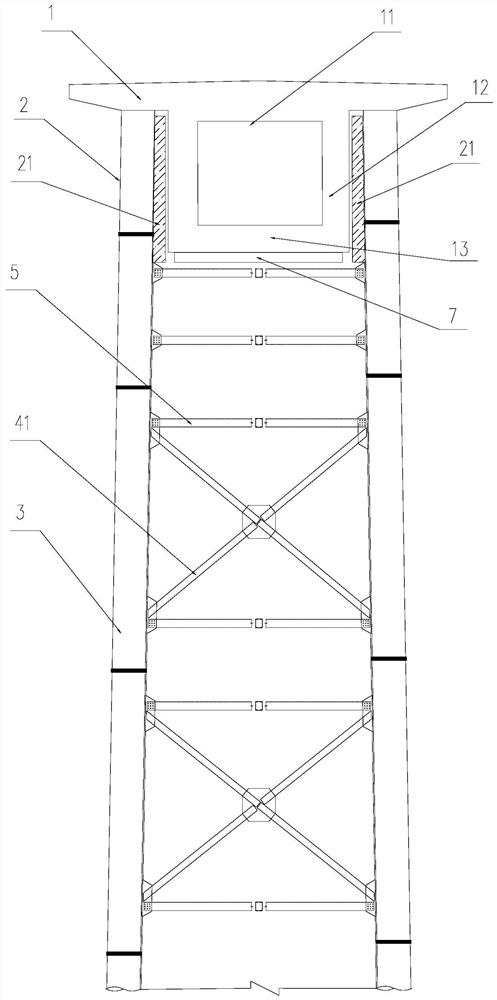

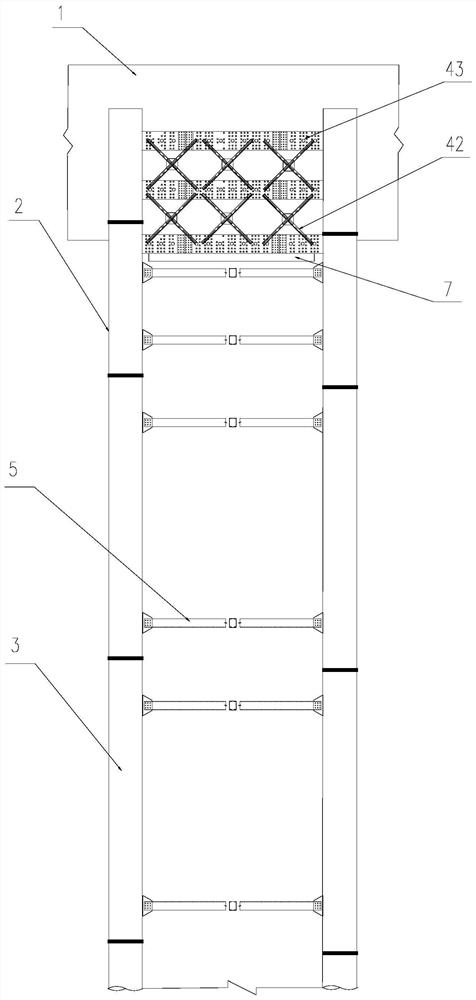

[0057] Such as Figure 2-Figure 8 As shown, a kind of anti-seismic bridge comprises main girder 1, bridge pier 2 and bearing platform 8, and the top surface of described pier 2 is higher than the bottom surface of described main girder 1, and the top of described pier 2 is provided with installation groove, and described main pier The beam 1 is located in the installation groove, and an anti-vibration cushion block 21 is arranged between the main beam 1 and the pier 2 in the transverse direction.

[0058] The platform 8 is provided with a reserved groove, the bottom of the pier 2 is located in the reserved groove, and concrete is poured in the reserved groove. The pier 2 includes four vertical steel pipes 3, the four steel pipes 3 are distributed on the four corners of the rectangle, and the part of the steel pipes 3 located in the reserved groove is provided with several second through holes 92 .

[0059] The bottom of the steel pipe 3 is welded with a pressure-bearing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com