Single-shaft transmission roller detachable three-high mill

A three-roll rolling mill with single-shaft transmission technology, which is applied in the direction of rolls, metal rolling stands, metal rolling mill stands, etc., can solve the problems of high frequency of roll replacement, large pass wear, and excessive wear. The effect of reducing maintenance costs, reducing input costs, and maintaining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

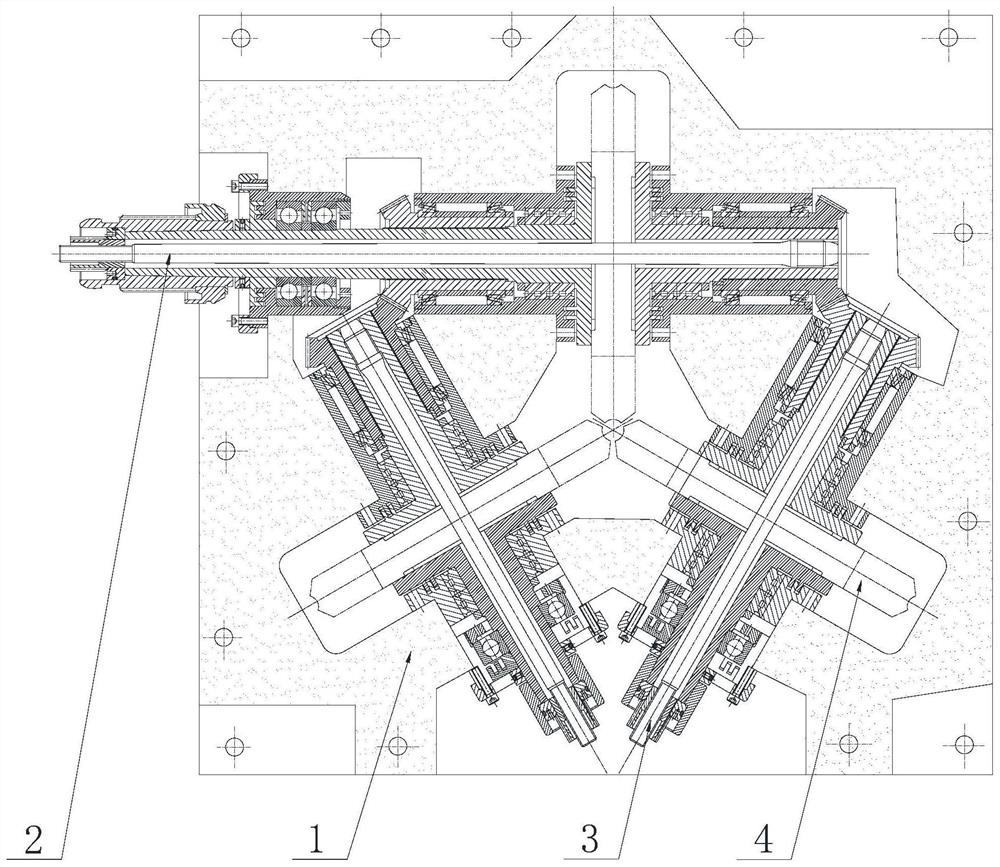

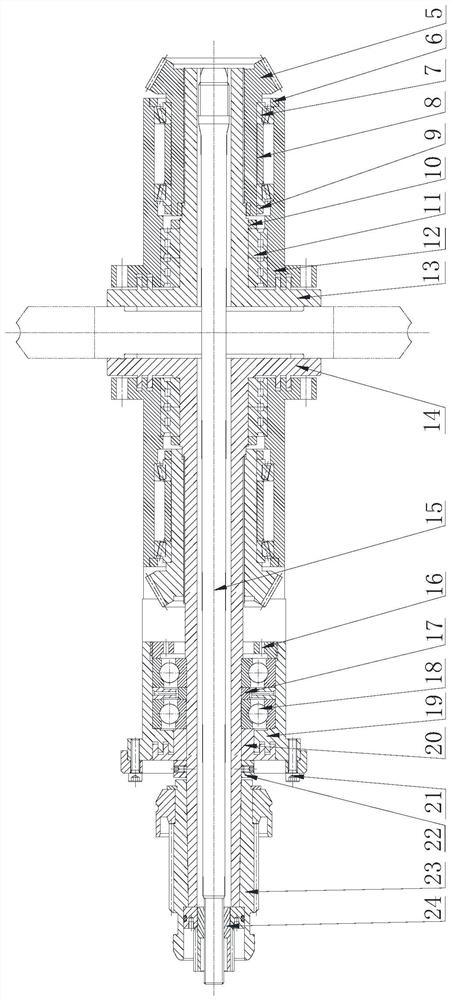

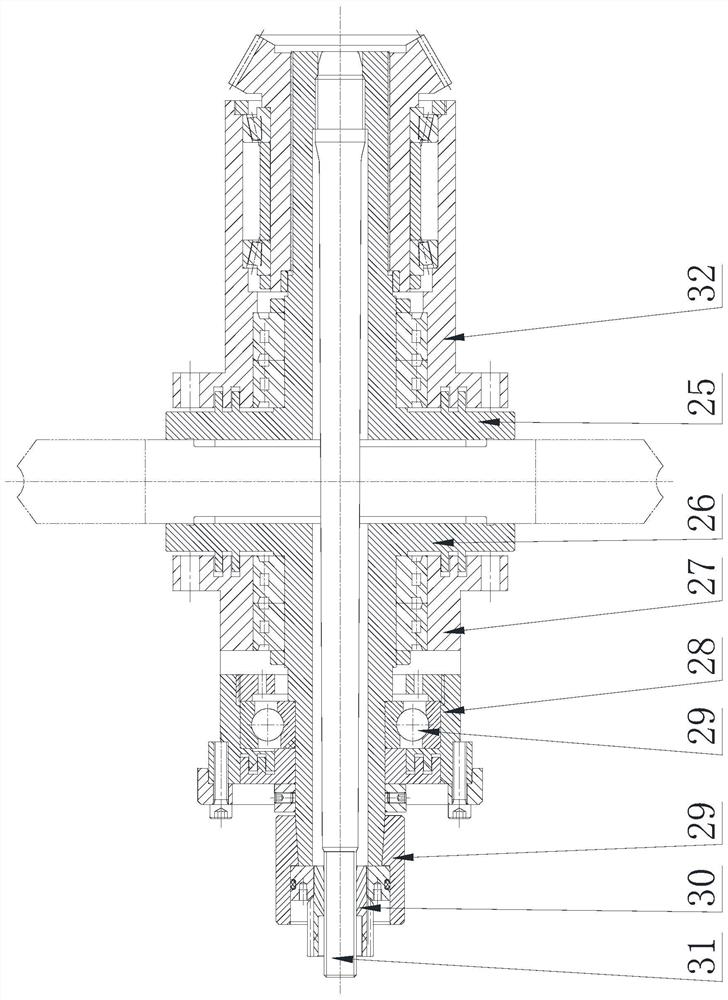

[0035] Such as figure 1 , figure 2 and image 3As shown, the three-roll rolling mill used in this embodiment is mainly aimed at the rolling of bars, especially the rolling of bars with arc triangular passes and tangential passes. One of the characteristics of the three-roll rolling mill in this embodiment is that the transmission structure is simple, and one drive shaft drives the other two drive shafts to rotate, without complicated transmission structure, simple installation, higher precision, and stable and reliable use for a long time; another feature Yes, it is easy to disassemble and maintain, and the disassembly and installation of the roll 4 can be quickly completed without affecting the accuracy of the work.

[0036] The single-shaft drive roll 4 detachable three-roll rolling mill includes a frame 1 and three sets of shaft assemblies arranged at 60° to each other on the frame 1. The frame 1 is a split structure, and the three sets of shaft assemblies include One s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com