Passive corona field lightning dispeller for high-speed rail

A technology of passive lightning drive and corona field, which is applied in the field of high-speed rail lightning drive, to achieve the effect of simple fixed installation, avoiding lightning strikes, and ensuring the safety of high-speed rail operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

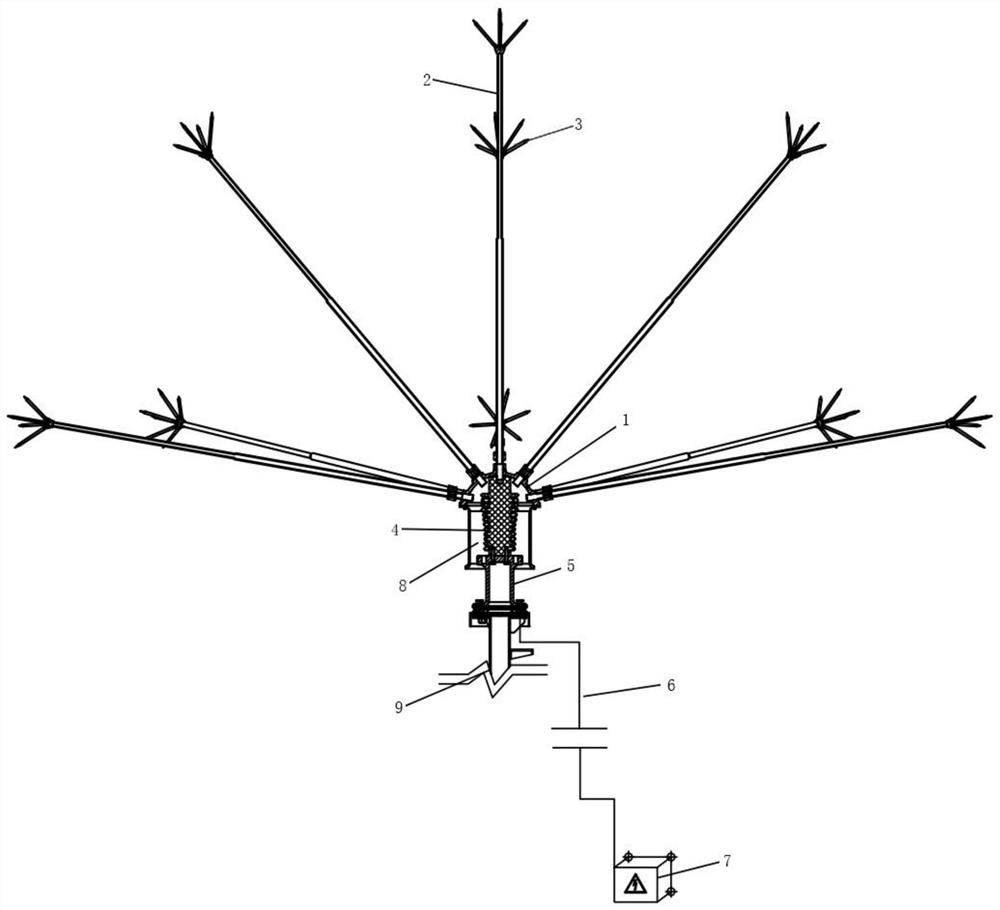

[0028] see figure 1 As shown, the present invention provides the following technical solutions: a passive corona field lightning drive for high-speed rail, including some passive lightning drives arranged at intervals along the high-speed rail track, and the passive lightning drive includes a bottom end with an opening A metal cover 1, a number of discharge rods 2 are evenly arranged on the outer wall of the metal cover 1, an insulating support 4 is installed on the inner wall of the opening end of the metal cover 1, and an electrode 5 is arranged at the bottom of the insulating support 4, between the electrode 5 and the inner wall of the metal cover 1 There is a discharge gap between them, and the ground wire 6 is connected to the electrode 5, and is connected to the earth through the ground wire 6.

[0029] In this embodiment, preferably, the distance between two adjacent passive corona field lightning drivers is 1-2 km.

[0030] In this embodiment, preferably, a discharge ...

Embodiment 2

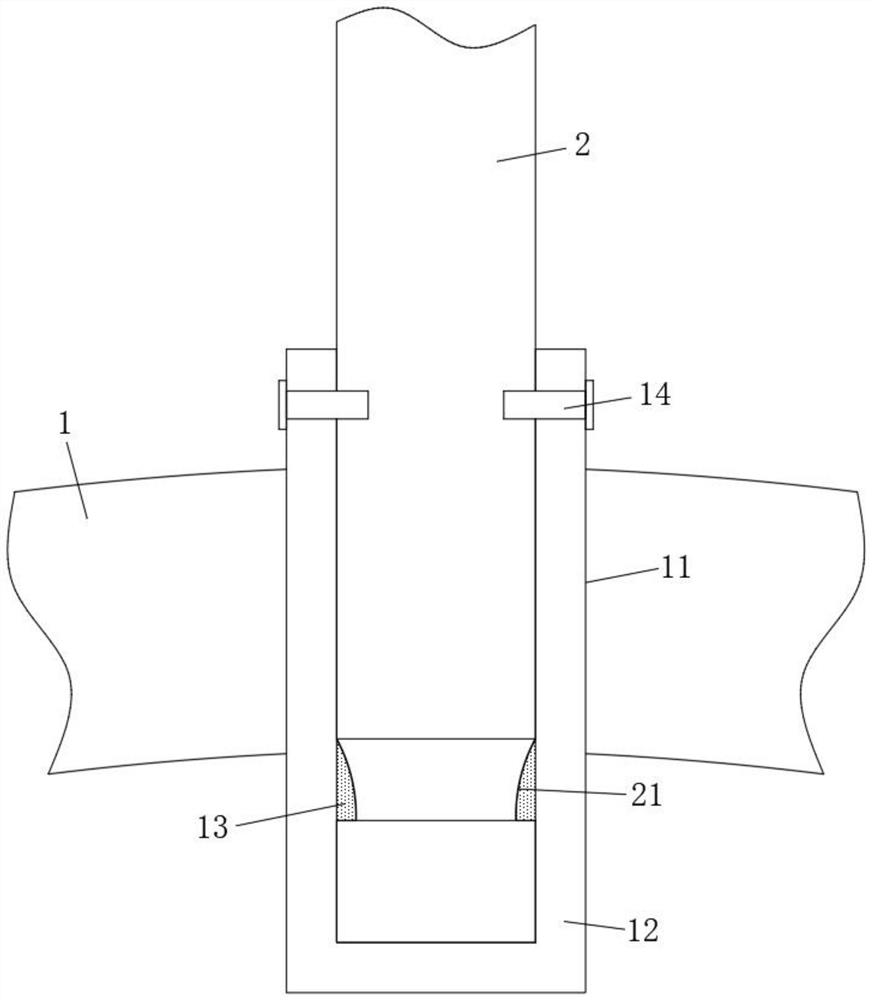

[0041] see figure 2 As shown, a plurality of discharge through-holes 11 are evenly opened on the metal housing 1, and a connection sleeve 12 is fixed through each discharge through-hole 11, and a plurality of discharge rods 2 are evenly fixed on the metal housing 1 through the connection sleeve 12,

[0042] In this embodiment, preferably, the inner wall of the connecting sleeve 12 is provided with a ring-shaped first buckle 13, and the outer wall of the discharge rod 2 is provided with a ring-shaped first locking groove 21, and the first locking groove 21 is connected with the first locking groove. The buckles 13 are engaged with each other.

[0043] In this embodiment, preferably, a first bolt 14 is fixed between the connection sleeve 12 and the discharge rod 2 , the first bolt 14 is located outside the metal housing 1 , and the first bolt 14 is coated with conductive thread glue.

[0044] Based on the structure disclosed in this embodiment, it can be seen that the principl...

Embodiment 3

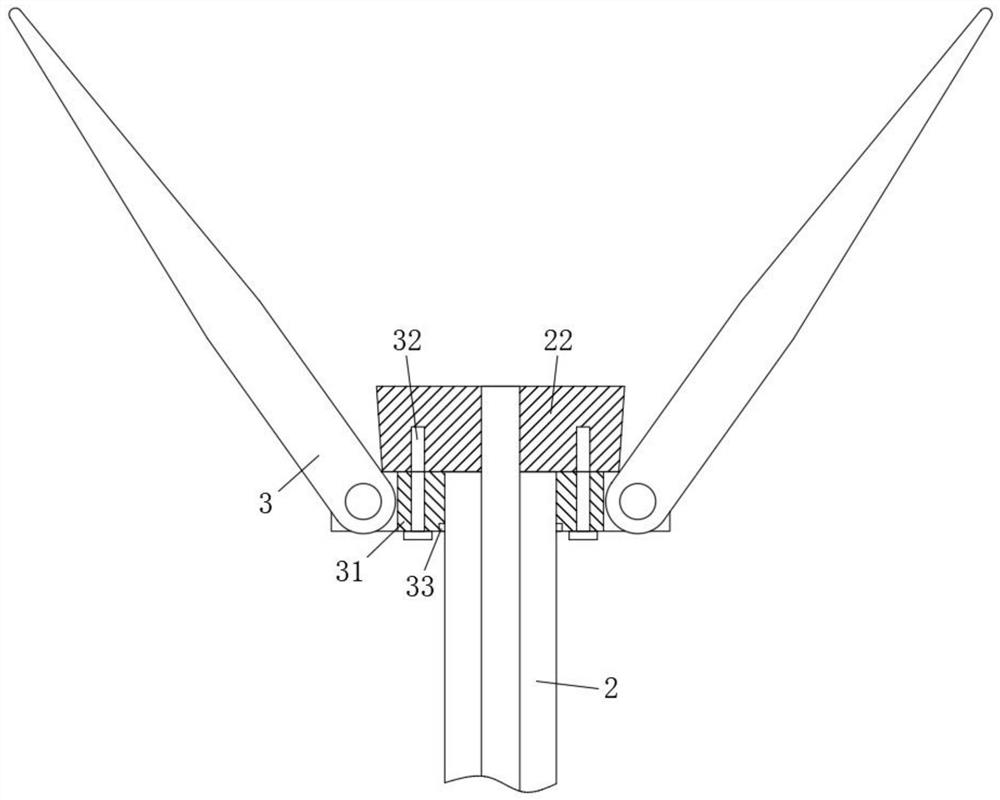

[0047] see Figure 3-Figure 4 As shown, the limit end 22 is welded on the end of the discharge rod 2 far away from the connecting sleeve 12, and the discharge rod 2 is also covered with a movable installation ring 31, and the discharge needle 3 is rotatably mounted on the installation ring 31, and the discharge needle The rotating installation structure of 3 includes a rotating shaft and a return spring connected between the rotating shaft and the mounting ring 31. A second bolt 32 is fixed between the limiting end 22 and the mounting ring 31, and the limiting end 22 is fixed to the mounting ring 31. , limit the discharge needle 3 to tilt outward.

[0048] In this embodiment, preferably, the second buckle 23 is set on the discharge rod 2, and the second buckle 33 is opened on the mounting ring 31, and when the second buckle 33 is engaged with the second buckle 23, the discharge Needle 3 is parallel to discharge rod 2.

[0049] Based on the structure disclosed in this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com