MXene composite material based electrochemical actuator and preparation method and application thereof

A composite material and composite material layer technology, which is applied to MXene composite material-based electrochemical actuators, and its preparation field can solve the problems of unfavorable MXene sheets, low motor torque quality, small piezoelectric ceramic strain, etc., and achieve bending deformation. The effect of large, fast response and low driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

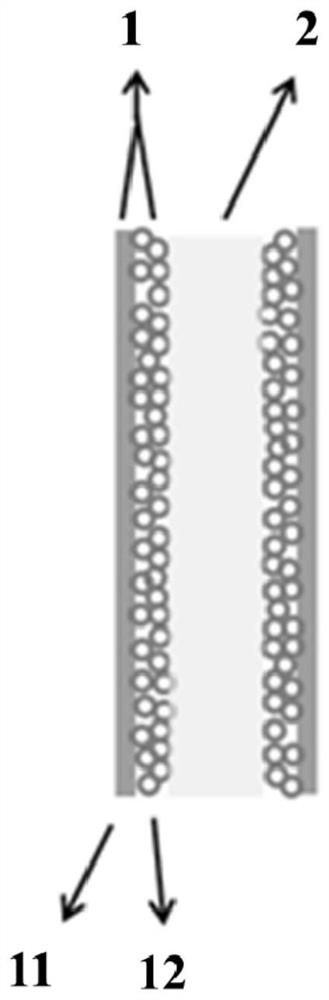

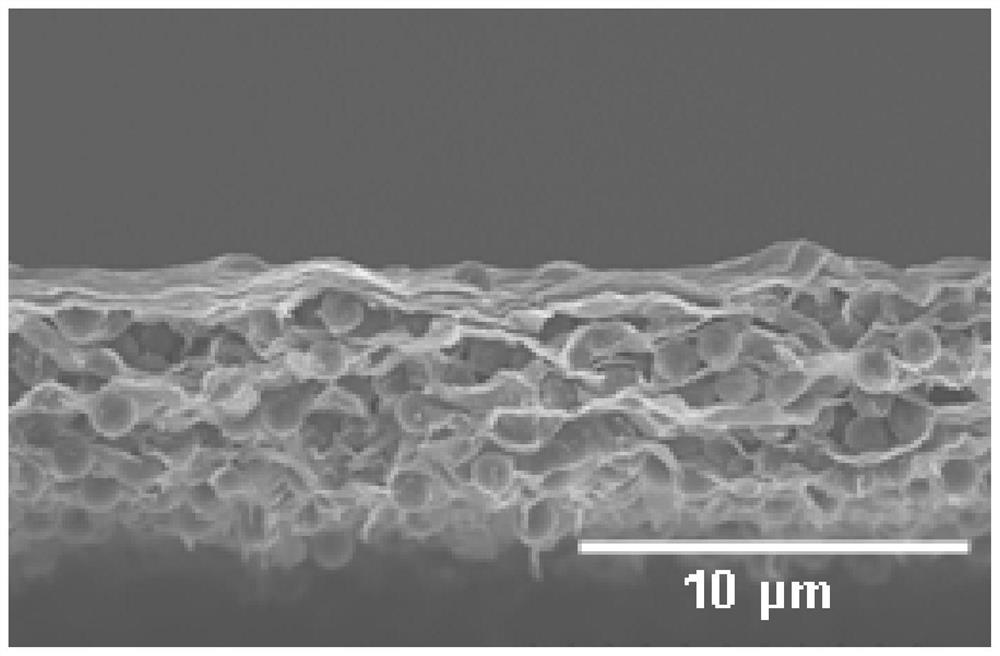

[0070] This embodiment provides a kind of MXene composite material-based electrochemical actuator (for its structural schematic diagram, see figure 1 ), the MXene composite material-based electrochemical actuator contains two layers of electrode layers 1 and one layer of electrolyte layer 2, and the electrolyte layer 2 is sandwiched between the two layers of electrode layers 1 to form a sandwich structure; the electrolyte layer 2 is EMIBF 4 / PVDF film with a thickness of 90 μm; each electrode layer 1 includes a first electrode material layer 11 (MXene layer) with a thickness of 0.5 μm and a second electrode material layer 22 (MXene / PS composite material layer, PS layer) with a thickness of 5 μm. The volume ratio with MXene is 4:1); The first electrode material layer 11 is the outer layer of the MXene composite material-based electrochemical actuator, which is in contact with air; the second electrode material layer 22 is an inner layer , which is in contact with the electrolyt...

Embodiment 2

[0089] The difference from Example 1 is that in the second electrode material layer, the volume ratio of PS to MXene is 1:1.

Embodiment 3

[0091] The difference from Example 1 is that in the second electrode material layer, the volume ratio of PS to MXene is 0.5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com