Casting and pouring system parameterized forming system and method based on creo software

A pouring system, parametric design technology, applied in electrical digital data processing, design optimization/simulation, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

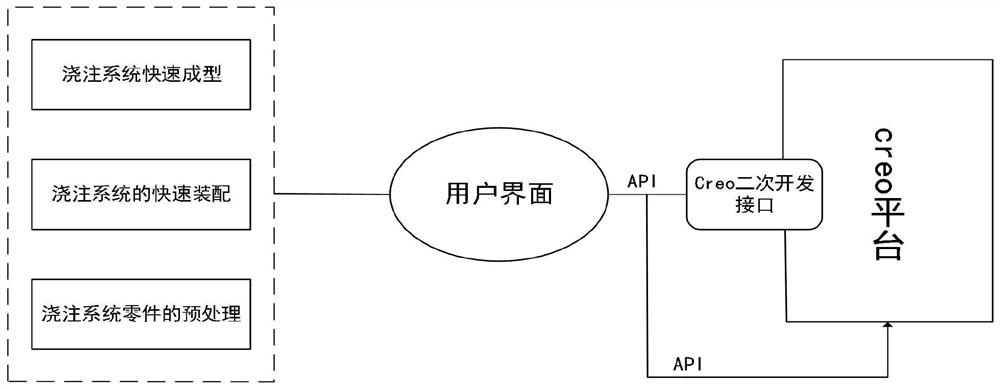

[0067] In this embodiment, the encapsulation of the three modules of the three-dimensional runner rapid generation module, rapid assembly module, and parts preprocessing module of the present invention is realized by means of the Visual Studio2010 compilation platform, and the MFC visual user interface is used under this platform, and at the same time through Creo The dynamic link between the provided application programming interface API (Application Programming Interface) and MFC realizes the seamless integration of the parametric molding system designed in this design and the Creo platform, such as figure 1 shown.

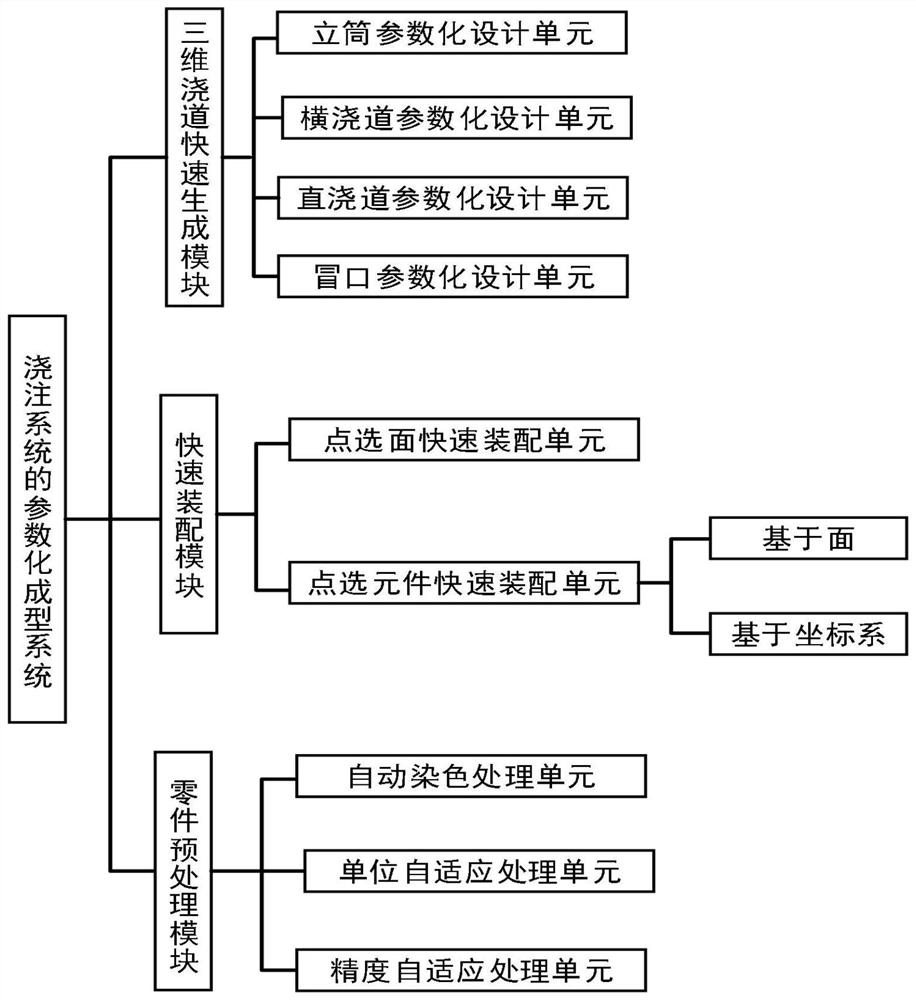

[0068] Such as figure 2 As shown, a parametric molding system based on casting gating system, including: three-dimensional runner rapid generation module, rapid assembly module, part pretreatment module;

[0069] The three-dimensional sprue rapid generation module includes: vertical cylinder parametric design unit, runner parametric design subunit, sprue param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com