Element mercury and divalent mercury standard gas generation system and working method thereof

A technology for generating system and divalent mercury, applied in standard gas analyzers, analyzing gas mixtures, and structural details of gas analyzers, etc., can solve problems such as fluctuations in the concentration of divalent mercury vapor, and achieve easy generation speed and reasonable structural design , full-featured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

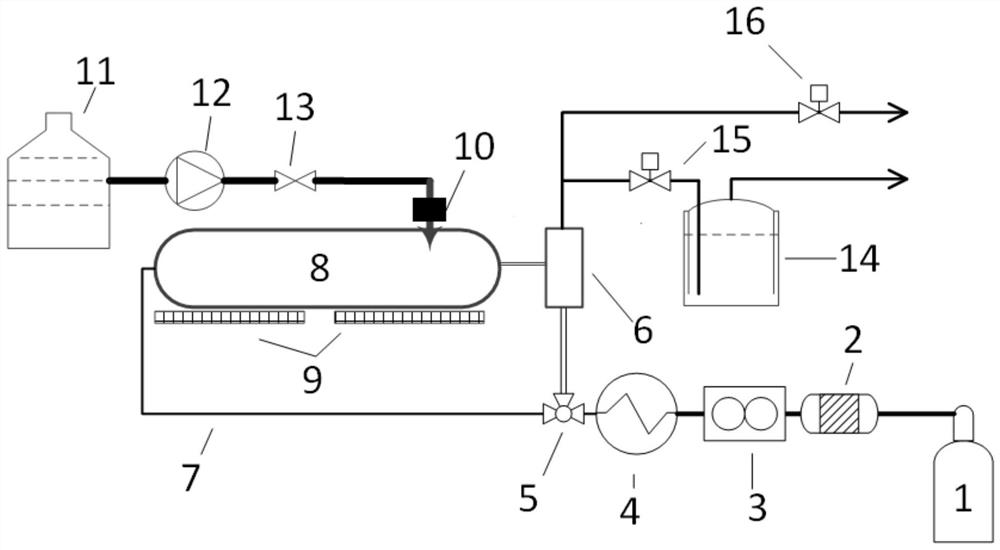

[0048] Step 1: add the mercuric chloride standard solution diluted with deionized water to the mercuric chloride standard solution storage device 11, its concentration M1, the shut-off valve 13 is closed, and the elemental mercury control valve 15 is closed;

[0049] Step 2: Set the temperature on the left side of the heating module 9 (the carrier gas pipeline 7 side) to 180°C, and the temperature on the right side of the heating module 9 to 160°C;

[0050] Step 3: Open the divalent mercury standard gas control valve 16, set the flow value V1 of the flow valve 3, set the temperature of the preheater 4 to 160°C, open the nitrogen gas storage device 1, and purge the system for 120 seconds;

[0051] Step 4: Turn on the pump 12, set the flow rate Q1, the mercuric chloride standard solution enters the gradient evaporation chamber 8 from the liquid inlet device 10, and vaporizes to generate divalent mercury vapor;

[0052] Step 5: The nitrogen gas in the carrier gas pipeline 7 enter...

Embodiment 2

[0056] Step 1: Add the mercuric chloride standard solution diluted with deionized water to the mercuric chloride standard liquid storage device 11, its concentration M2, add reducing agent 10% tin protochloride solution to the reduction reactor 14, the shut-off valve 13 closed state , the divalent mercury calibration gas control valve 16 is closed;

[0057] Step 2: Set the temperature on the left side of the heating module 9 (the carrier gas pipeline 7 side) to 180°C, and the temperature on the right side of the heating module 9 to 160°C;

[0058] Step 3: Open the elemental mercury control valve 15, set the flow value V2 of the flow valve 3, set the temperature of the preheater 4 to 160°C, open the nitrogen gas storage device 1, and purge the system for 120 seconds;

[0059] Step 4: Turn on the pump 12, set the flow rate Q2, the mercuric chloride standard solution enters the gradient evaporation chamber 8 from the liquid inlet device 10, and vaporizes to generate divalent merc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com