Beer outlet valve of beer machine

A technology of beer machine and wine outlet, which is applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of long purging time, cumbersome two independent purging, affecting the taste, etc., and achieves efficient purging or cleaning. Purge efficiency with no residue, control or ease of operation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to clearly illustrate the technical characteristics of this patent, the following describes this patent in detail through specific implementation methods and in conjunction with the accompanying drawings.

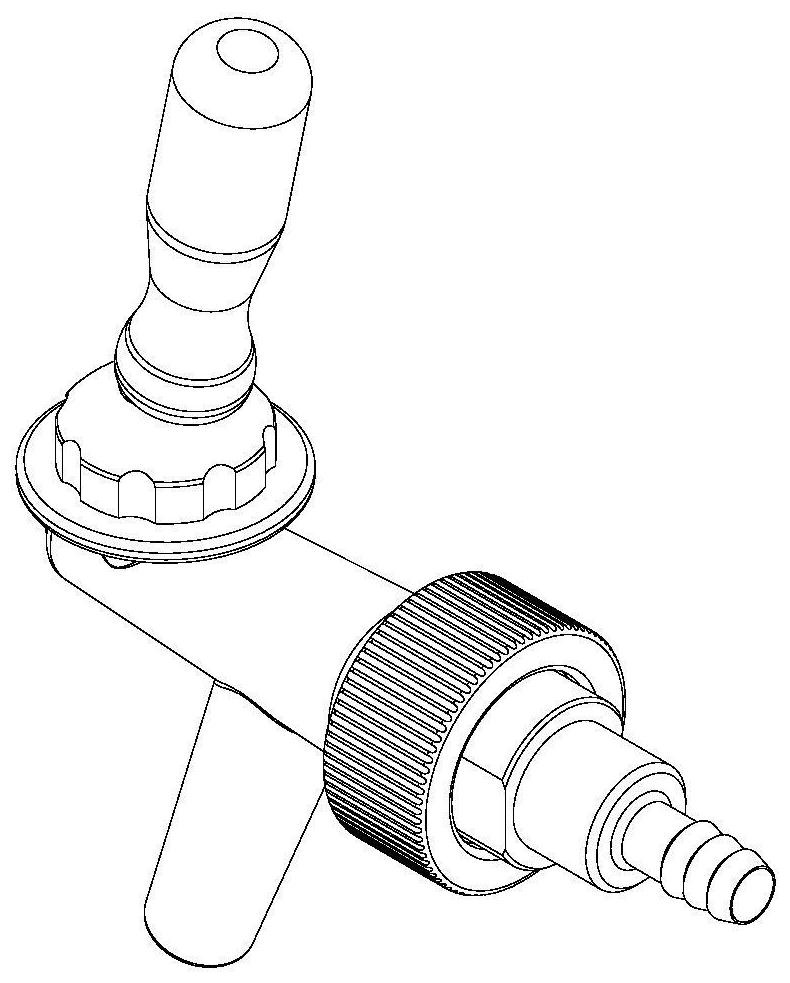

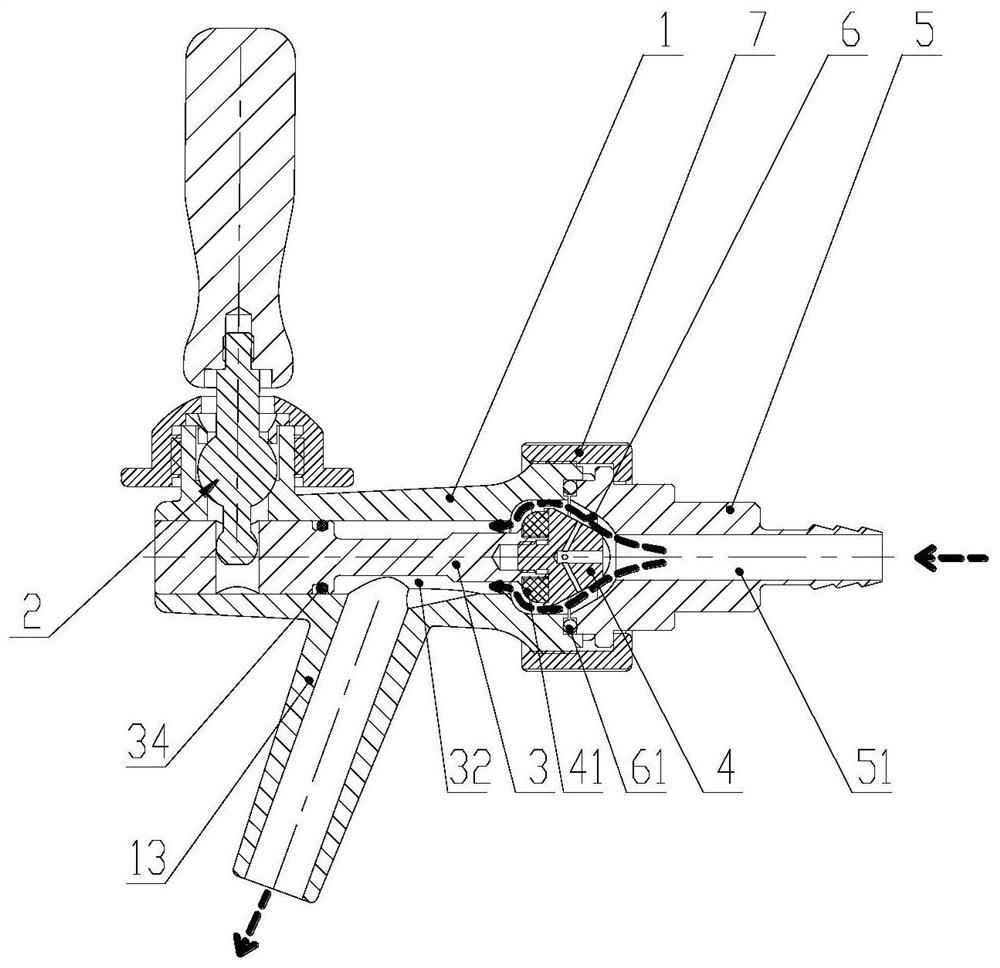

[0044] The present invention as Figure 1-6 As shown, it includes a valve body 1, a lever 2 and a valve stem 3. The valve body 1 is provided with a valve stem hole 11 adapted to the valve stem 3, and an operating hole 12 is provided on the side wall of the valve body 1. , the bottom of the valve body 1 is provided with a wine outlet pipe 13 communicating with the valve stem hole 11, and the side wall of the valve stem 3 is provided with a flow passage 32 communicating with the wine outlet pipe 13, and the valve stem 3 is slidably arranged in the valve stem hole 11, and the valve stem 3 is provided with a driving hole 31 for accommodating the driving rod 2, the driving rod 2 is hinged with the valve body 1, and the driving rod 2 passes through the The operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com