Bamboo charcoal fiber production equipment with moisture regain-proof function

A technology of bamboo charcoal fiber and production equipment, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., and can solve the problems of bamboo charcoal moisture and affecting the performance of bamboo charcoal fiber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

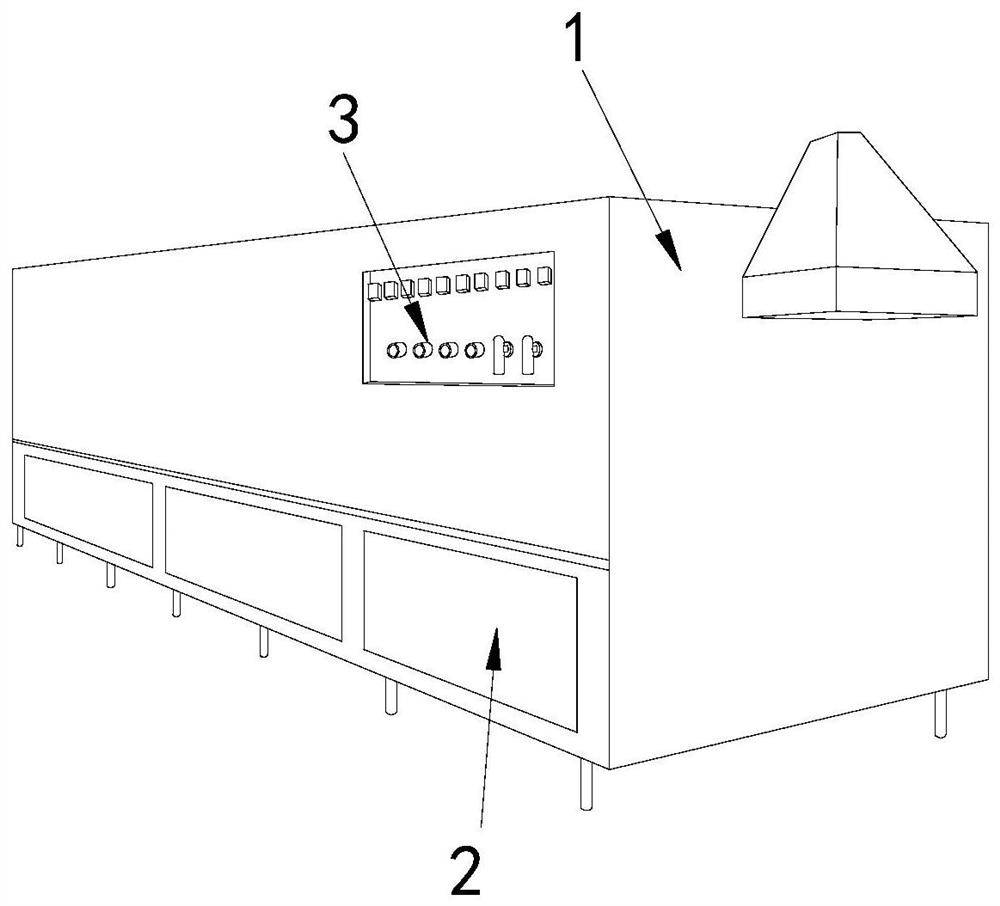

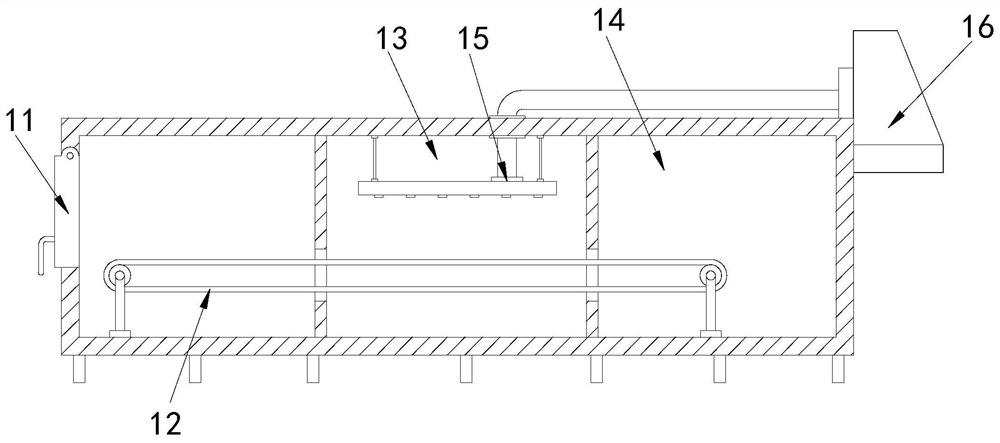

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

[0027] Its structure includes a main body 1, a box door 2, and a control panel 3. The front end of the main body 1 is provided with three box doors 2, and the box doors 2 are horizontally installed on the bottom of the front end of the main body 1. The main body 1 includes a feed port 11 , conveyor belt 12, drying box 13, jet pipe 14, collection box 15, air extraction device 16, the feed inlet 11 is installed on the side end of the main body 1, the conveyor belt 12 is horizontally installed inside the main body 1, the The drying box 13 is located in the middle of the main body 1, the air injection pipe 14 is arranged on the top of the drying box 13, the collection box 15 is located at the end of the main body 1, and the collection box 15 is embedded in the drying box 13. At the top, the suction device 16 is installed on the outer side end of the main body...

Embodiment 2

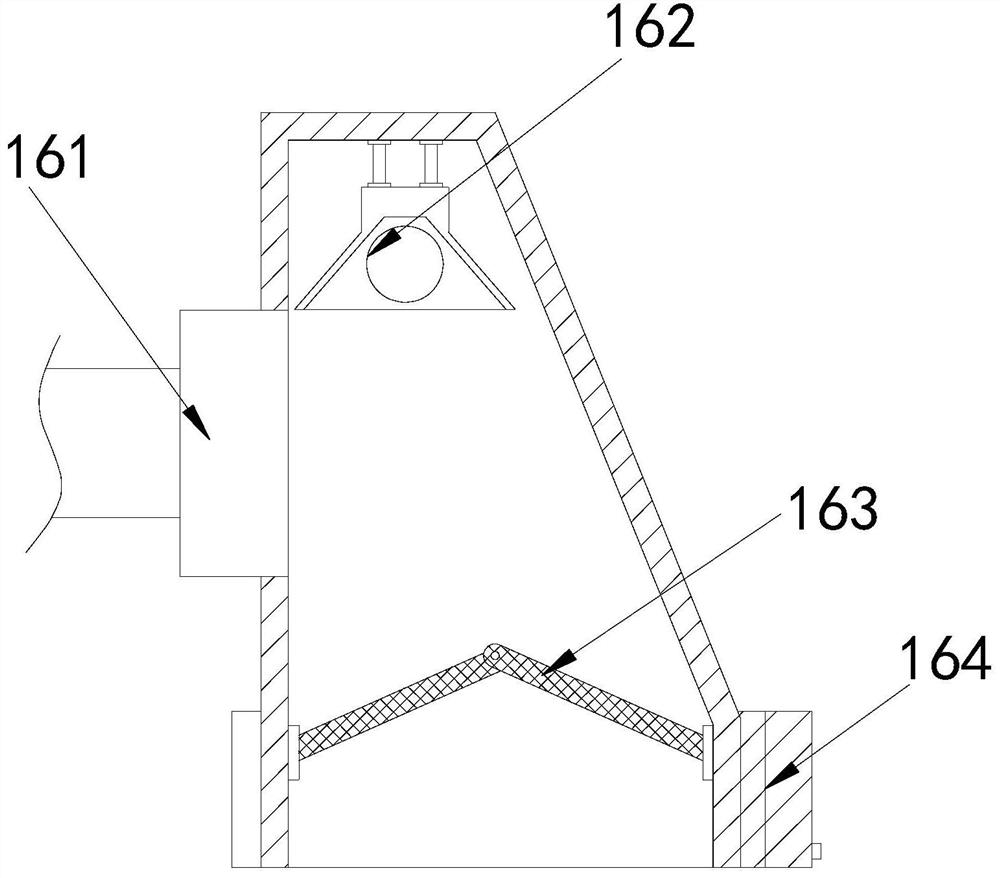

[0032] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0033] The water collecting device 164 includes a water storage tank b1, a water receiving block b2, a water outlet b3, a water storage tank b4, and a drain b5. The water collecting tank b1 is arranged around the water collecting device 164, and the water receiving block b2 is provided with Two, installed on the inner side of the water collection device 164, and communicated with the water tank b1, the water outlet b3 is located at the bottom of the water tank b1, and communicated with the water storage tank b4, and the drain b5 is installed in At the bottom of the side end of the water storage tank b4, the depth of the water storage tank b1 gradually deepens from one end to the other end, which is conducive to the concentrated flow of water to the water storage tank b4.

[0034]The water receiving block b2 includes a bolt hole b21, a groove b22, a connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com