Gas-phase cluster reaction device and reaction system and method

A technology of reaction device and reaction system, which is applied in the field of cluster reaction, can solve the problem that it is difficult to eliminate the interference of solvents on clusters, and achieve the effects of easy control of gas phase pressure, convenient position adjustment, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

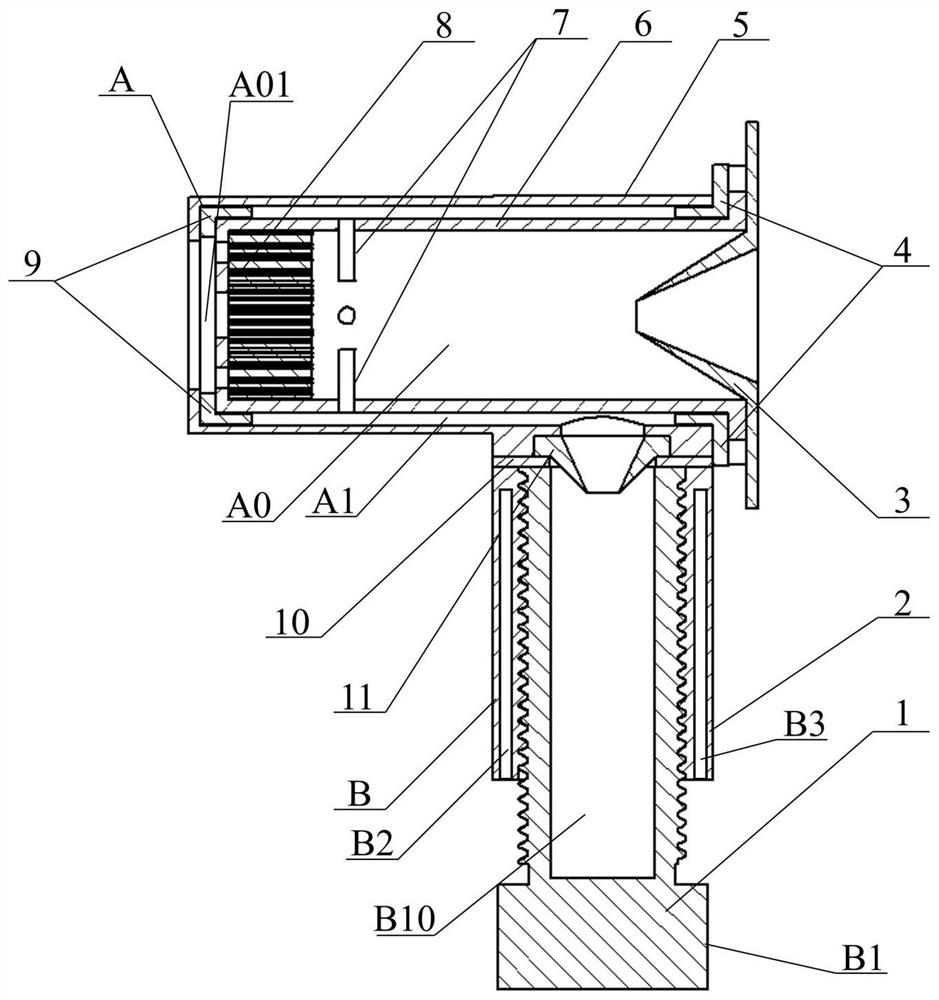

[0049] Such as image 3 , 4 , 5, 6, according to an embodiment of the present invention, the telescopic assembly B1 includes a base 2 and a hollow tube 1, the outer wall of the hollow tube 1 is screwed to the inner wall of the base 2, and the hollow tube 1 One end is closed, the other end is open, and the other end is used to communicate with the reaction chamber A0, and the inner side of the one end of the hollow tube 1 forms the evaporation chamber to the connection between the telescopic assembly and the reaction component B10.

[0050] The hollow tube 1 can be a hollow tube with one end closed and one end open. Alternatively, the hollow tube 1 can be a hollow screw. The structure of the hollow tube 1 is not limited by the enumerated embodiments, and other equivalent transformations can be made. The hollow tube can be made of stainless steel, and the hollow part is used to place solid organic matter, and the distance between the solid organic matter and the reaction par...

Embodiment

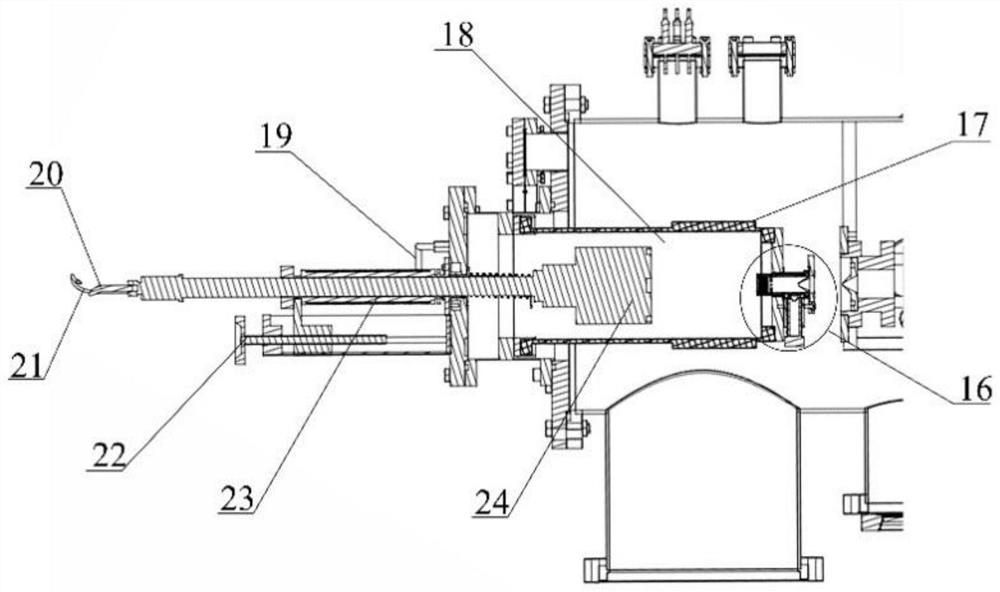

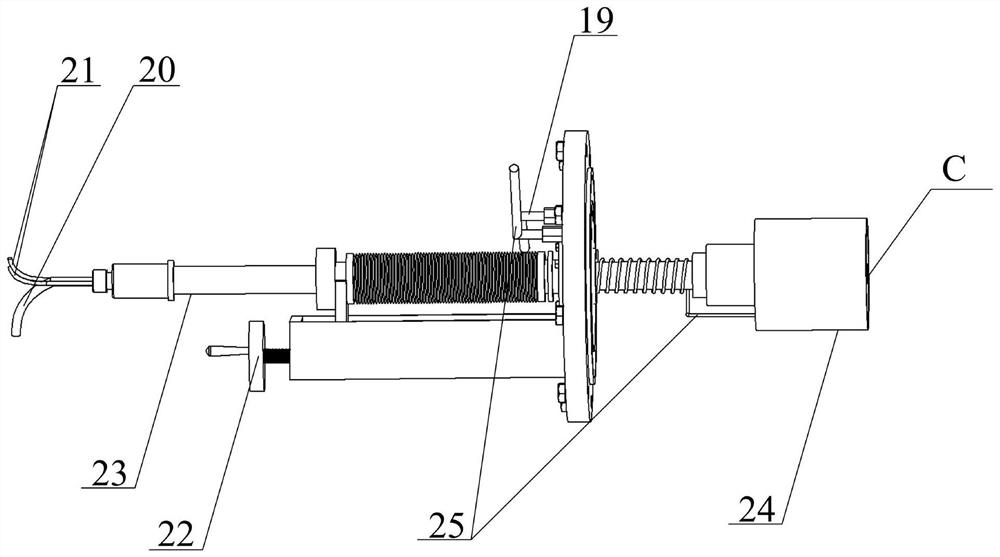

[0095] Such as figure 1 and 2 , the cluster preparation device with adjustable magnetron head supported by translation slide rail mainly includes ion source vacuum chamber 18, magnetron head distance adjustment rod 22 and magnetron sputtering target gun installed in the ion source vacuum chamber. The magnetron sputtering target gun mainly includes a magnetron head 24 equipped with a metal target, a sputtering gas delivery pipe 25 , a buffer gas delivery pipe 19 and a circulating cooling water pipe 21 .

[0096] The magnetron head 24 equipped with the metal target is connected to the cathode of the DC power supply 20; the sputtering gas delivery tube 25 is wound on the magnetron rod 23, and one end thereof is in close contact with the metal target.

[0097] The buffer gas delivery pipe 19 is directly connected to the vacuum chamber 18 of the ion source.

[0098] The material of the sputtering gas delivery pipe 25 is a polyethylene hose, which can be stretched back and forth, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com