A lifting mechanism, a lifting and rotating mechanism and an automatic guided vehicle

A technology of lifting mechanism and rotating mechanism, which is applied in the field of warehousing and logistics, can solve the problems of complex adjustment and installation of multiple screw screws, the impact of hollow screw life, and the limitation of AGV miniaturization trends, etc., to achieve simple structure and reduce control The effect of difficulty and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This embodiment discloses an automatic guided vehicle with a lifting function, referred to as AGV. The AGV includes a mobile carrier and a lifting mechanism 100 .

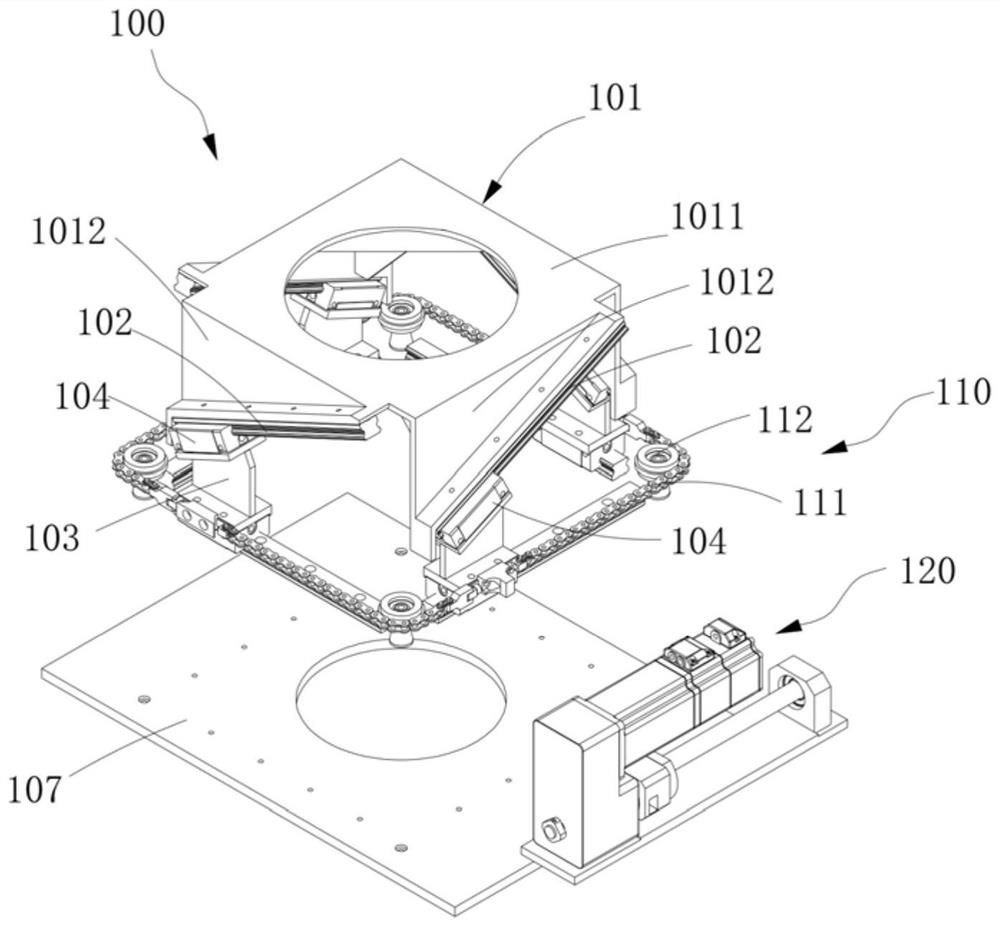

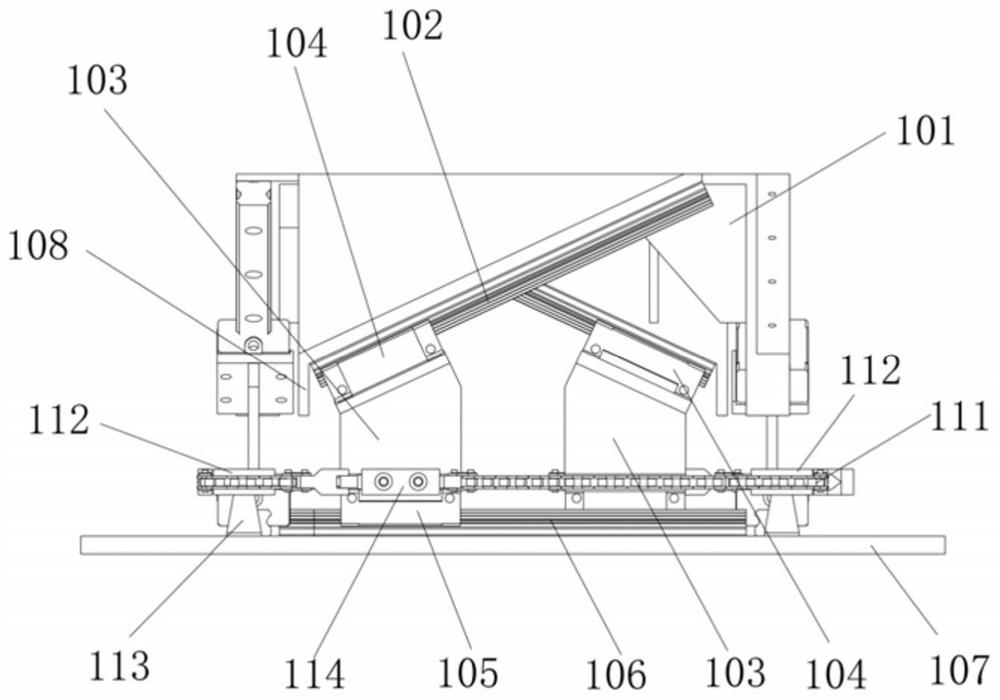

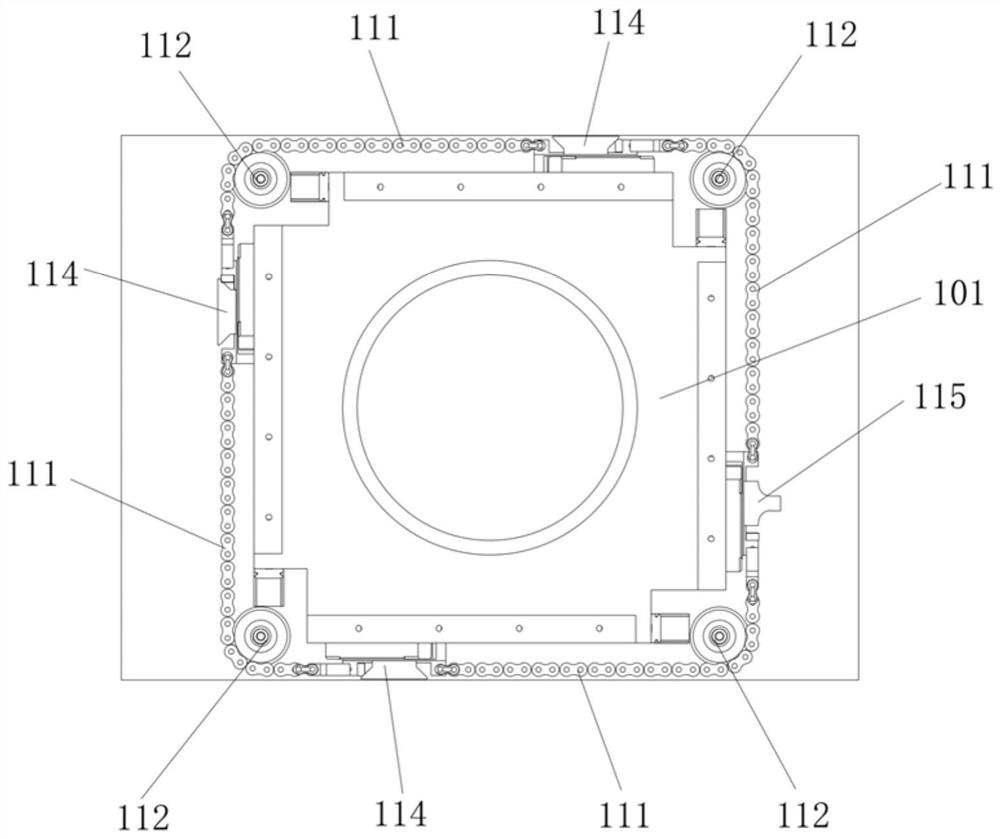

[0065] specifically, figure 1 It is an exploded view of a lifting mechanism 100 in Embodiment 1 of the present invention; figure 2 It is a side view of a lifting mechanism 100 in Embodiment 1 of the present invention; image 3 It is a top view of a partial structure of a lifting mechanism 100 in Embodiment 1 of the present invention. refer to Figure 1-3 , the lifting mechanism 100 includes a lifting frame 101 , a rail top plate 103 , a transmission assembly 110 and a lifting drive assembly 120 connected to the transmission assembly 110 . Wherein the lifting frame 101 comprises a lifting plate 1011 and a vertical side wall 1012 supporting the lifting plate 1011, and the vertical side wall 1012 is uniformly provided with at least two slanting guide rails 102 along the circumferential direction; The numb...

Embodiment 2

[0071] This embodiment discloses an automatic guided vehicle with a lifting and rotating function, referred to as AGV. The AGV includes a mobile carrier and a lifting and rotating mechanism.

[0072] specifically, Figure 7 It is an exploded view of a lifting and rotating mechanism in Embodiment 2 of the present invention; Figure 8 It is an exploded view of a lifting and rotating mechanism for removing the tray 300 in Embodiment 2 of the present invention. refer to Figure 7 and 8 , the lifting and rotating mechanism may include the lifting mechanism 100 in Embodiment 1, and further include a rotating mechanism 200 disposed on the lifting mechanism 100 . Wherein the rotary mechanism 200 comprises a rotary drive assembly 201, the body of the rotary drive assembly 201 is connected with the lifting frame 101 of the lifting mechanism 100, the output end of the rotary drive assembly 201 is connected with a third gear 202, and the lifting plate 1011 of the lifting mechanism 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com