Aircraft foot control mechanism assembling method

An assembly method and a foot-operated technology are applied to aircraft assembly, aircraft power units, aircraft parts, etc., which can solve the problems of assembly error accumulation, inconvenient use and maintenance, and narrow construction space, so as to reduce adjustment cycle and adjustment time, Effect of reducing adjustment and assembly cycle and improving adjustment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] This part is the embodiment of the present invention, which is used to explain and illustrate the technical solution of the present invention.

[0028] A method for assembling an aircraft foot control mechanism, comprising the following steps:

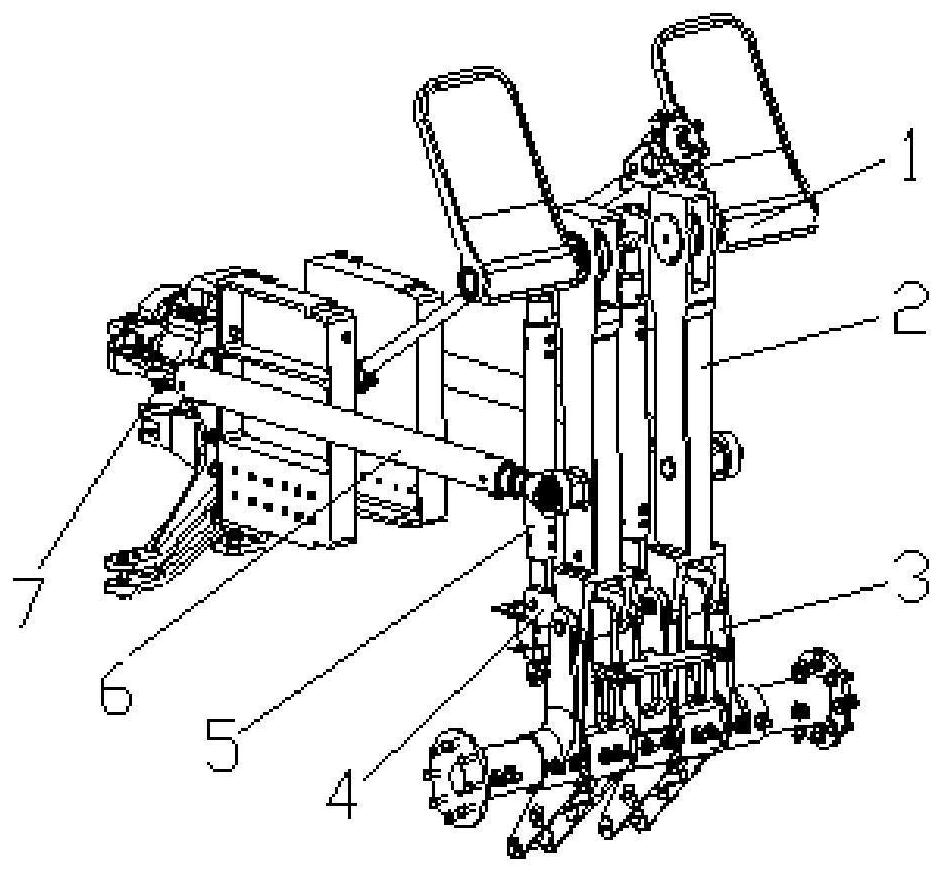

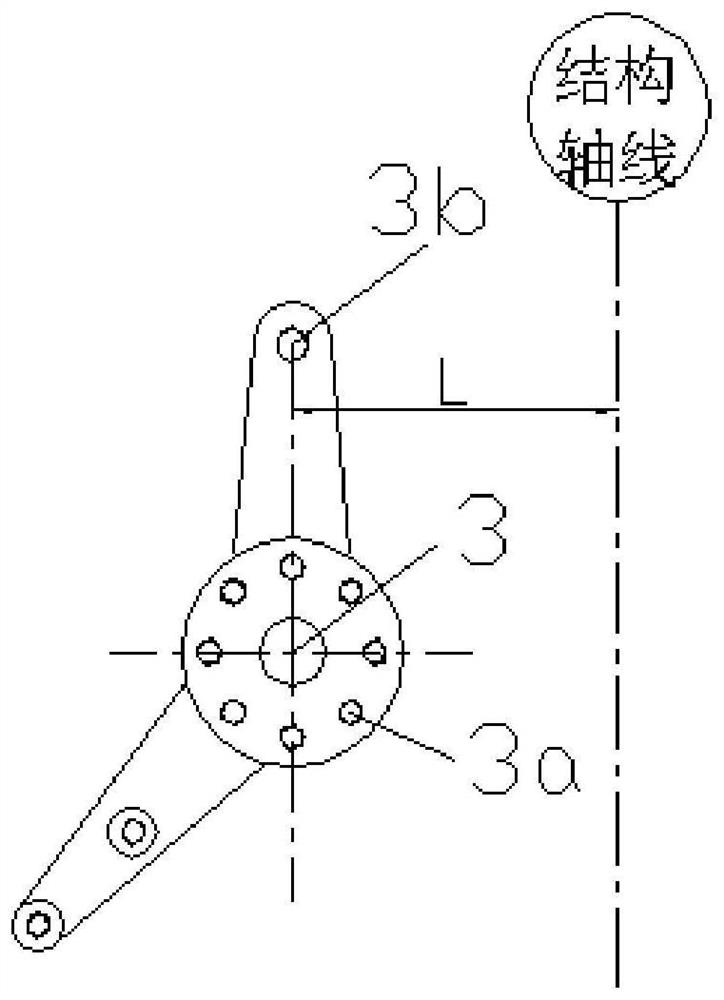

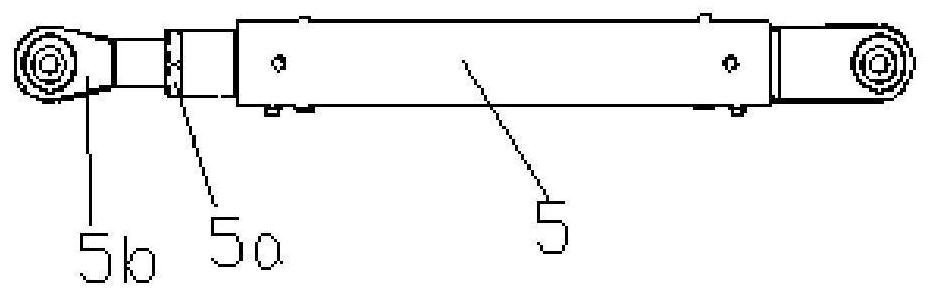

[0029] Step 1, adjust the axial distance between the foot control fixed bracket 3 and the aircraft structure to be the theoretical distance L, then manufacture the connecting hole 3a between the foot control fixed bracket 3 and the aircraft structure, install the foot control fixed bracket 3 on the aircraft structure; adjust the brake The length of the pull rod 5 reaches the specified size;

[0030] Step 2: Assemble pedal 1, pedal column 2, connect rocker arm 4 and brake lever 5, and fine-tune the length of brake lever 5 so that the connecting rocker arm 4 is perpendicular to pedal column 2;

[0031] Step 3: Complete the assembly of the rocker arm 7 and the connection between the rocker arm 7 and the aircraft structure to ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com