Six-color rotary press for printing bills and manufacturing method thereof

A manufacturing method and technology of rotary presses, which are applied in printing presses, rotary presses, offset rotary presses, etc., can solve the problems that sheet-fed offset presses cannot meet market demands, products are prone to wrinkles, and substrates are not flat, etc. To achieve the effect of reducing clogging, avoiding adhesion, and uniform movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

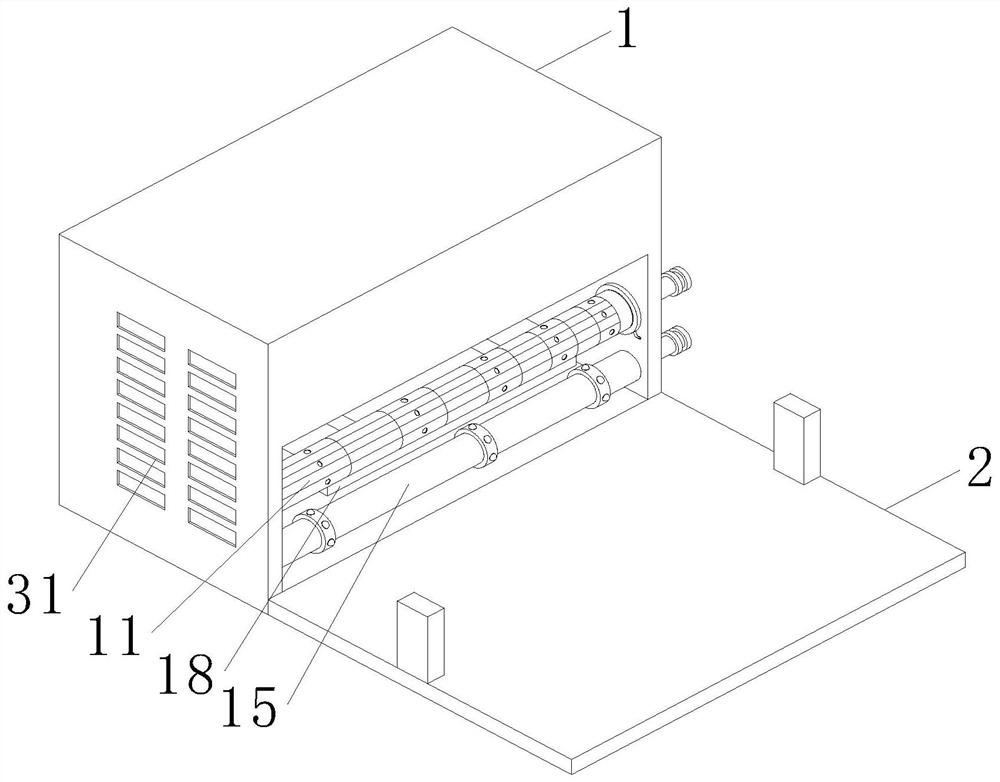

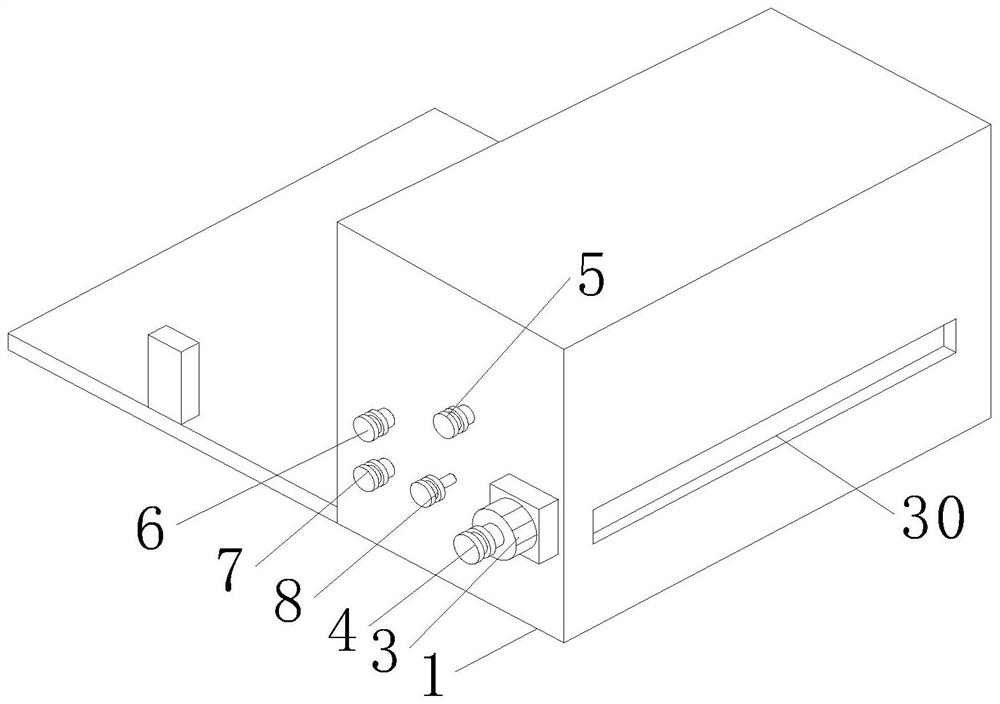

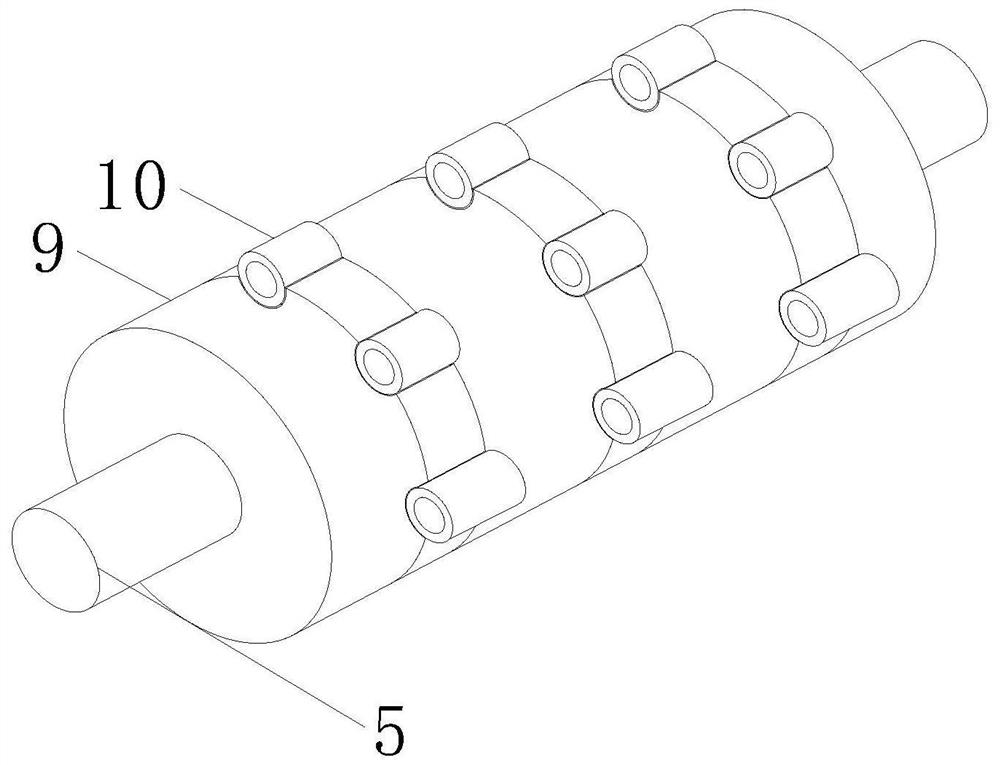

[0033] Embodiments of the present invention provide a six-color rotary machine for printing bills and a manufacturing method thereof, such as Figure 1-9 As shown, it includes a rotary machine body 1 and a support plate 2, the support plate 2 is arranged on one side of the rotary machine body 1, the rotary machine body 1 is fixedly connected with the support plate 2, and the support plate 2 can be used to hold printed bills Blocking blocks are set on the front and back of the support plate 2 to prevent bills from falling. A paper release hole 30 is provided on one side of the rotary machine body 1. The paper release hole 30 is used to deliver blank paper sheets. The through hole 31 and the heat dissipation through hole 31 can play a role in cooling the interior of the rotary machine body 1, increase the contact between the interior of the rotary machine body 1 and the outside air, and dissipate the temperature accumulated during work, which is conducive to the continuous printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com