A method to enhance heat transfer in dry cutting machining considering chip heat transfer

A technology for enhancing heat transfer and dry cutting, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of the effect of compressed air-assisted heat dissipation and temperature control, the law of heat flow and the efficient regulation of its effect, etc. To achieve the effect of improving the heat transfer capacity of chips, enhancing the ability of cutting heat, and reducing the thermal deformation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings.

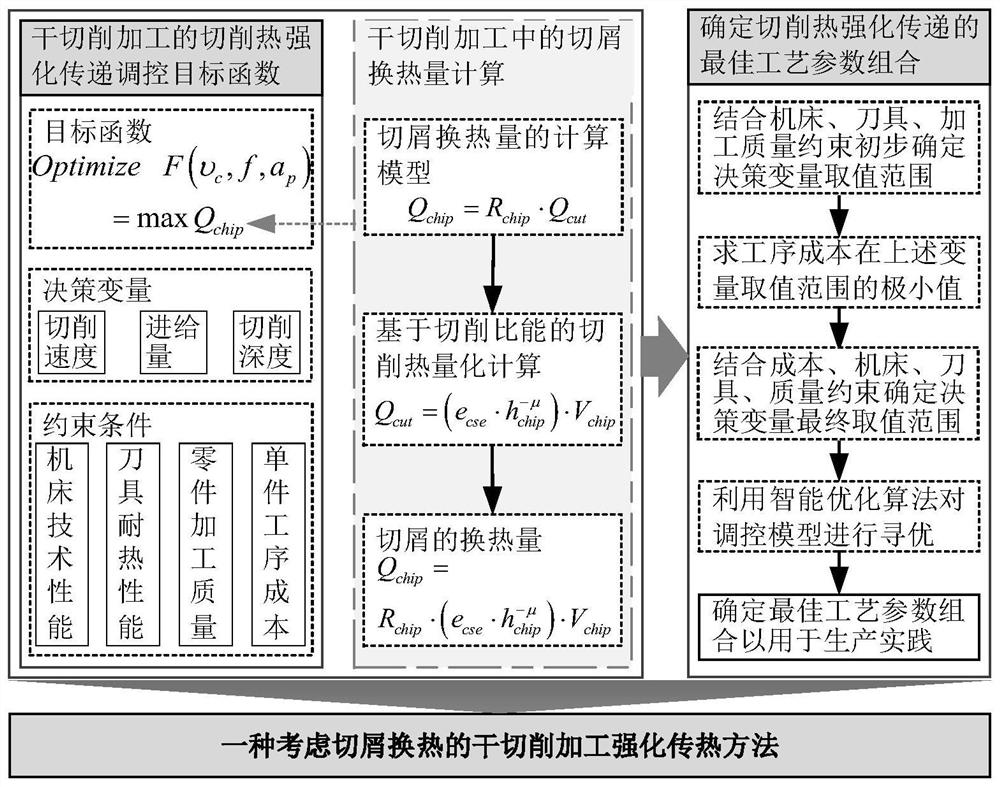

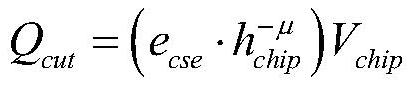

[0049] Such as figure 1As shown, the present invention discloses a method for enhancing heat transfer in dry cutting considering chip heat transfer, including:

[0050] S1. Constructing a cutting heat enhancement transfer control objective function for dry cutting. The cutting heat enhancement transfer control objective function takes the maximum chip heat transfer as the control target, and takes cutting speed, feed rate, and cutting depth as decision variables;

[0051] S2. Establish the constraint conditions of the cutting heat enhancement transfer control objective function corresponding to the target workpiece that satisfies the lowest single-piece process cost and matches the technical performance of the machine tool, the heat-resistant temperature of the tool, and the processing quality of the part;

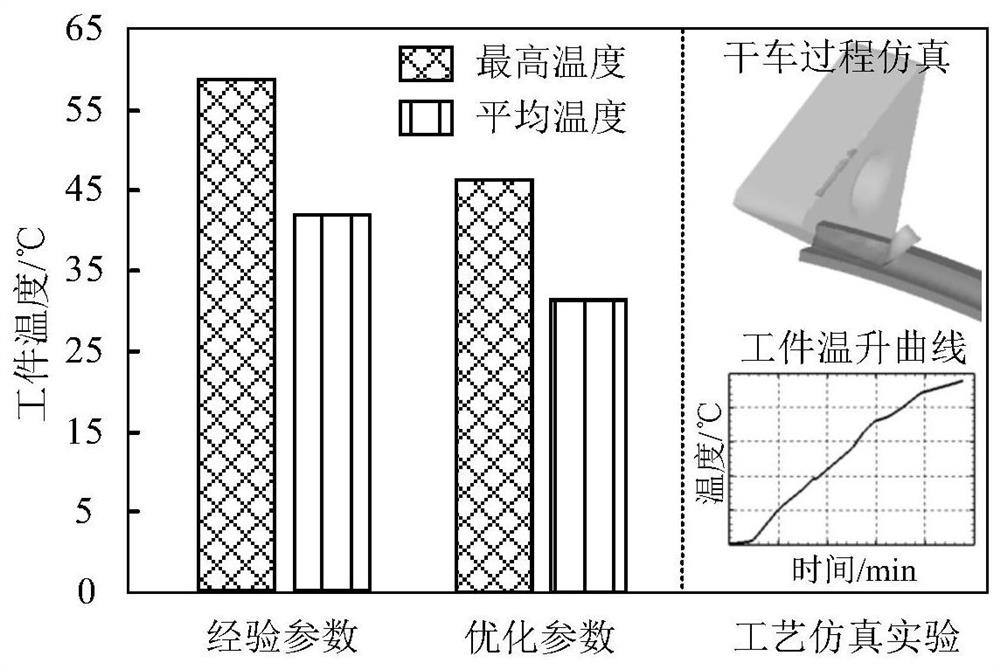

[0052] S3. Based on the constraint conditions of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com