Machining press fitting equipment provided with structure capable of carrying out positioning and preventing abnormal movement

A technology for machining and equipment, applied in the field of press-fitting equipment with a positioning and anti-change structure for machining, can solve the problems of poor assembly quality of workpieces, low work efficiency, and affect the accuracy of workpieces, so as to improve assembly quality and production. The effect of high efficiency and good regulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

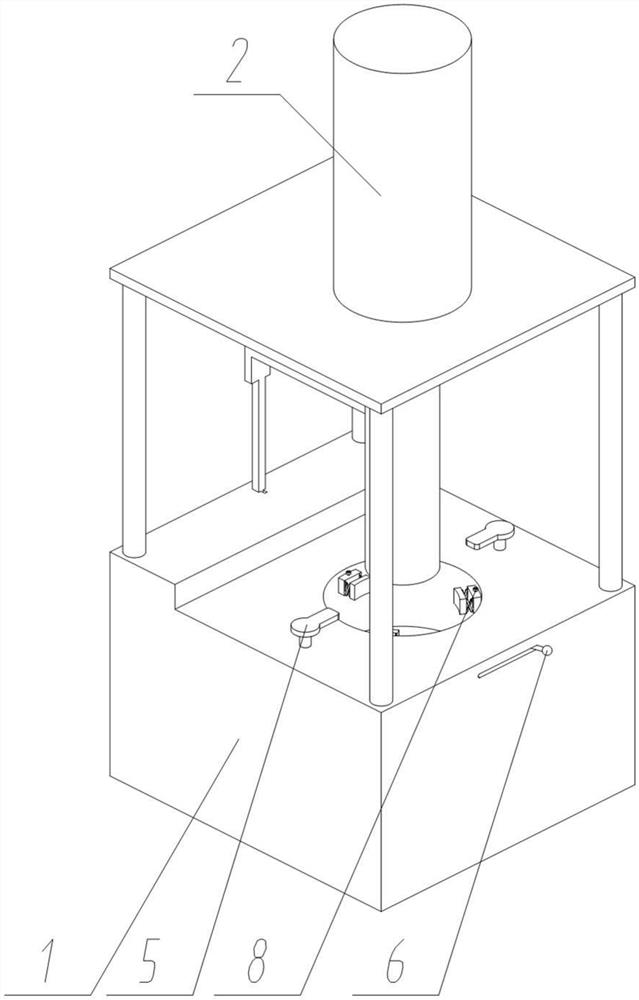

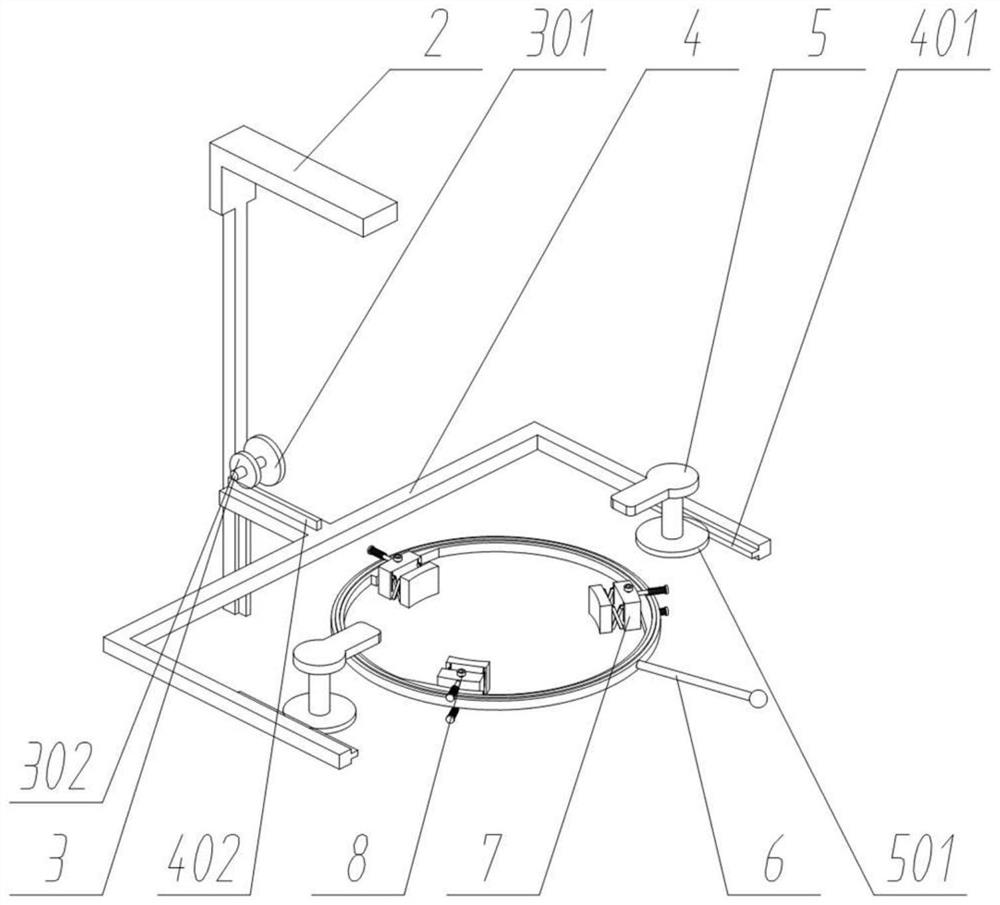

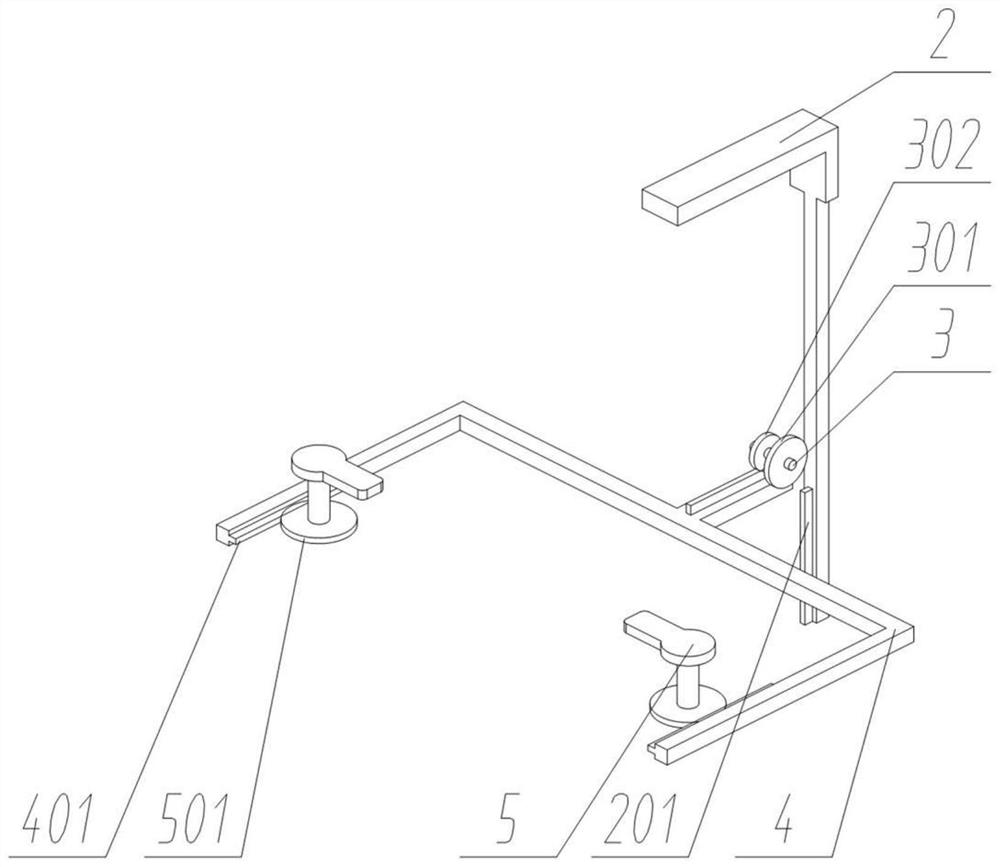

[0030] See Figure 1 to Figure 8 The press-fitting equipment provided with a positioning and anti-shift structure for machining provided by the present invention includes an outer casing 1; the top of the outer casing 1 is fixedly connected with a set of hydraulic cylinders 2; the inner and rear of the outer casing 1 is rotatably connected with a set of intermediate transmission parts 3; The upper and inner sides of the outer shell 1 are slidably connected to a set of driving sliders 4; the upper part of the outer shell 1 is rotatably connected to a set of rotating pressing plates 5; the upper inner side of the outer shell 1 is rotatably connected with a set of clamping operating members 6; Three sets of clamping mounting blocks 7 are connected in a circular array and slidingly connected; the inside of the clamping mounting block 7 is connected with a set of clamping blocks 11 through two pairs of adjusting links 10; the top of the clamping mounting block 7 is rotatably connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com