Top plate drilling equipment and method for installation of decoration lamps of buildings

A technology for lamp installation and architectural decoration, applied in drilling/drilling equipment, metal processing equipment, manufacturing tools, etc. The effect of improving operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

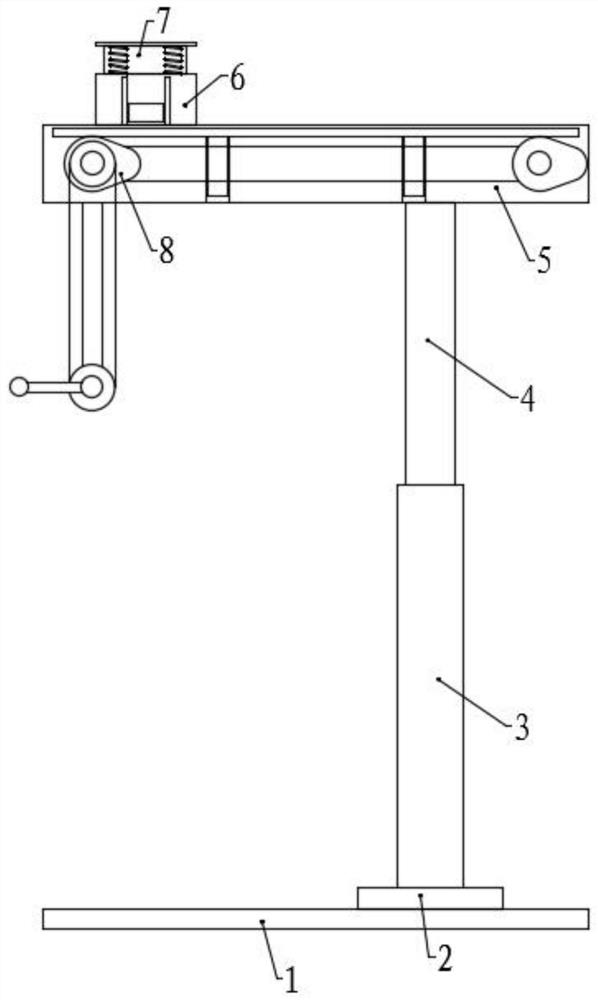

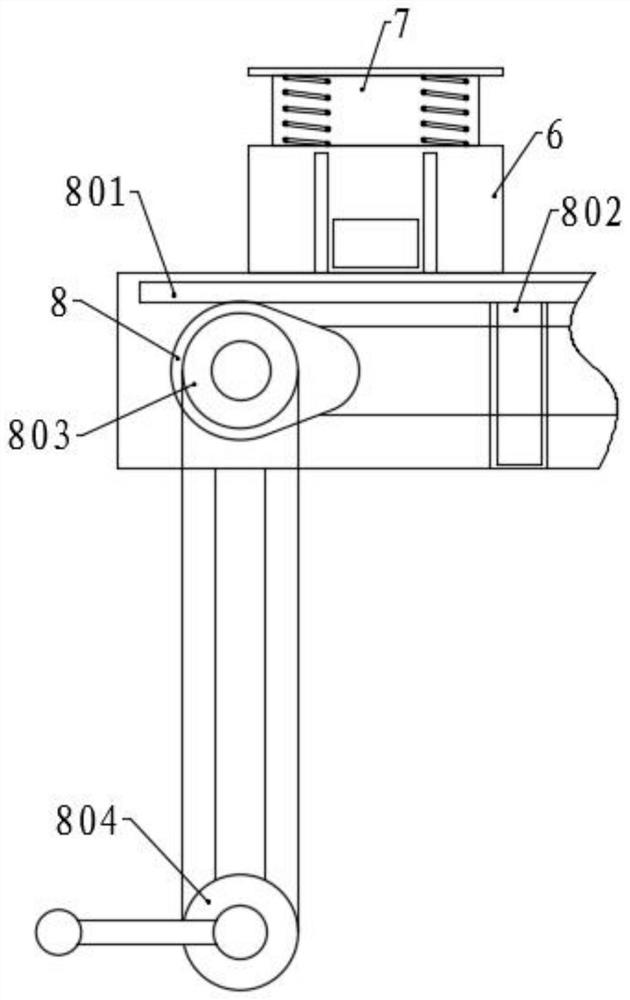

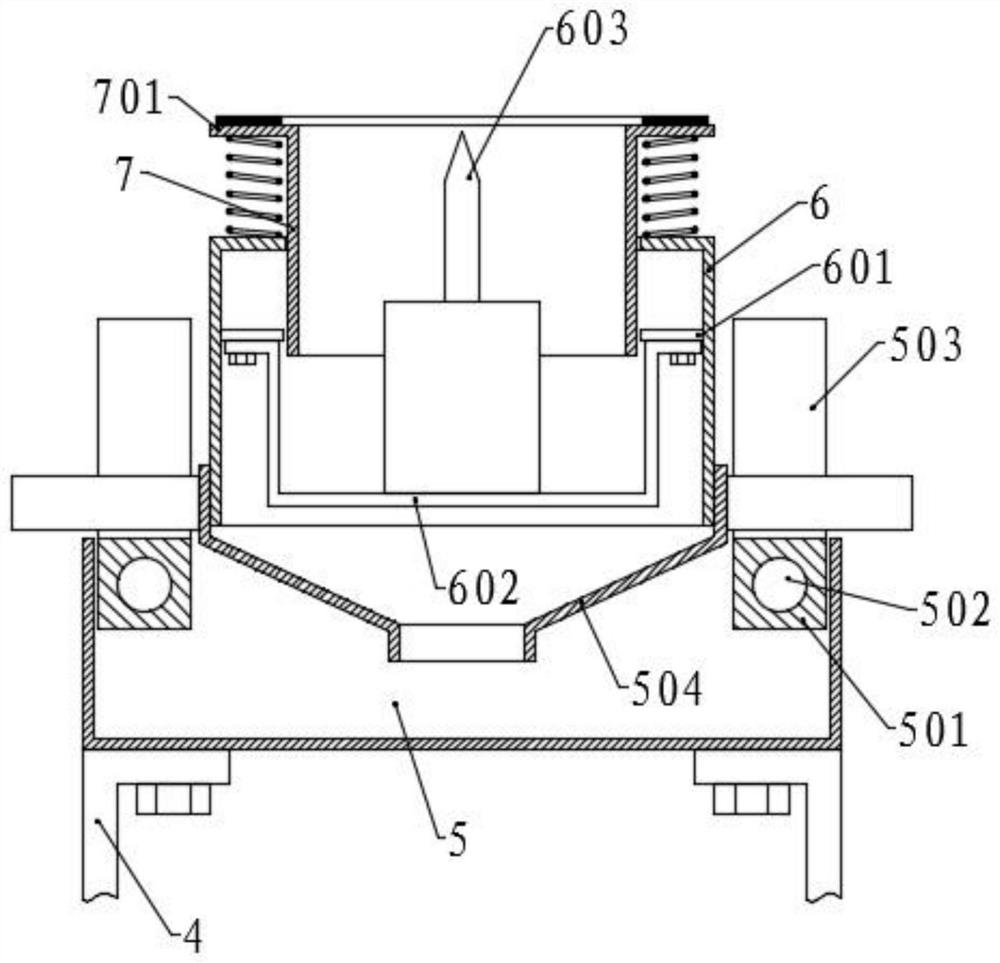

[0054] Please refer to the accompanying drawings, the present invention provides a technical solution: a roof drilling device for installing architectural decorative lamps, including a base 1, the four corners of the bottom surface of the base 1 are provided with rollers, brakes are provided on the rollers, and the top surface of the base 1 The right side is rotatably connected with a rotating seat 2, the side wall of the rotating seat 2 is fixed with a bevel gear 201, and the first bevel gear 202 is meshed with the bevel gear 201, and the first bevel gear 202 is connected with a motor, and the rotating seat 2 A lifting assembly is arranged on the top of the lifting assembly, and a fixed groove 5 is fixed on the top of the lifting assembly. The interior of the fixed groove 5 is provided with a horizontal movement assembly, and the outside is provided with a vertical movement assembly. The moving blocks are symmetrically fixed on both sides, and the moving blocks are correspondi...

Embodiment 2

[0068] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a lower hopper 505 is fixed on the side of the bottom surface of the fixing groove 5 away from the lifting assembly, and a threaded pipe 506 is fixed on the bottom of the lower hopper 505, and the threaded pipe 506 is connected with the fixed The bottom surface of the groove 5 is fixedly connected, and the threaded pipe 506 is threadedly connected with a collecting tube, and the fixed groove 5 is rotatably connected with an inclined blanking plate 9, and the lower end of the blanking plate 9 is positioned above the blanking hopper 505. The middle bottom surface of the plate 9 and the bottom surface of the fixed groove 5 are provided with a spring, and the bottom surface of the blanking plate 9 is provided with a second cam 901 away from the side of the lower hopper 505, and the second cam 901 is fixed with a camshaft 902, and the camshaft 902 is rotatably connected with...

Embodiment 3

[0071]The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the middle of the bottom surface of the fixing groove 5 is slidably connected with the third slider 1002 along the length direction, the bottom surface of the third slider 1002 is fixed with an indicator light 1003, and the third slider 1002 is fixed on the bottom surface, and the second The third screw rod 10 is sleeved on the three sliders 1002, and the third screw rod 10 is rotationally connected with the bottom surface of the fixed groove 5, and a fifth pulley 1001 is fixed on one end, and the end surface of the fixed groove 5 corresponds to the fourth pulley 507 The position between the fifth pulley 1001 is rotationally connected with an adjustment wheel 508, and the fourth pulley 507, the fifth pulley 1001 and the adjustment wheel 508 are connected by a transmission belt, and the position of the transmission belt is adjusted by the adjustment wheel 508 so that the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com