Ultrasonic duel sleeve coil pipe type milk liquid sterilizing system

A double-coiled, milk technology, applied in the preservation of milk, dairy products, applications, etc., can solve problems such as troublesome ultra-high temperature instantaneous sterilization operation, damage to nutrients and flavor, and short shelf life of dairy products. Scaling and coking phenomenon, ensuring effective sterilization, mild and stable heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

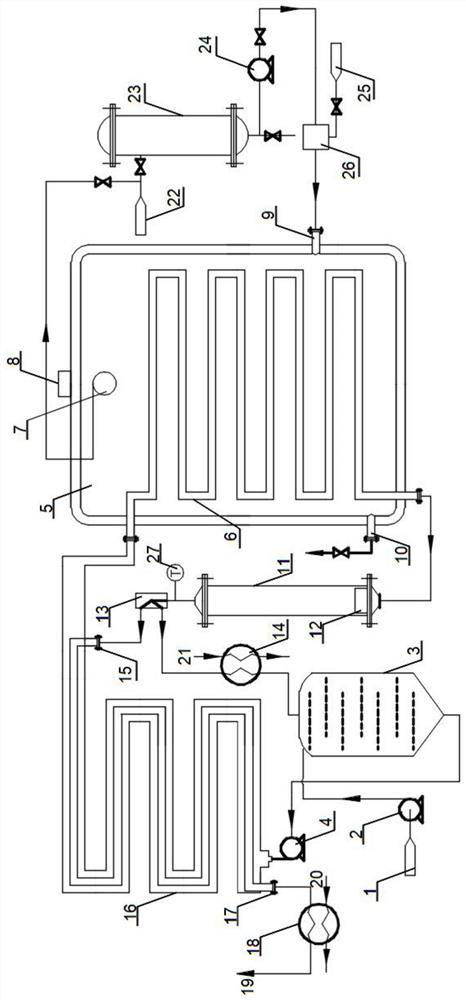

[0023] An ultrasonic dual-coil milk sterilization system is characterized in that it includes a feed tank 1, a balance tank 3, a double-coil 16, a coil 6, a heating chamber 5, a holding pipe 11 and a heat source unit. The feed tank is connected to the balance tank through the feed pump 2, and the balance tank is connected to the double-set coil pipe through the aseptic pump 4, and a coil pipe is annularly arranged in the heating chamber, and the two ends of the coil pipe are Both protrude from the heating chamber, the double-set coil is connected to one end of the coil, the other end of the coil is connected to the holding pipe, and a reversing valve 13 is arranged on the top of the holding pipe. One end of the reversing valve is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com