Semiconductor MPS diode with reduced current-crowding effect and method of manufacturing same

A diode and semiconductor technology, which is applied in the field of semiconductor fusion PN-Schottky diodes, can solve the problems of local electrothermal runaway, MPS device failure, and the inability to ensure rapid diffusion of bipolar conduction current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

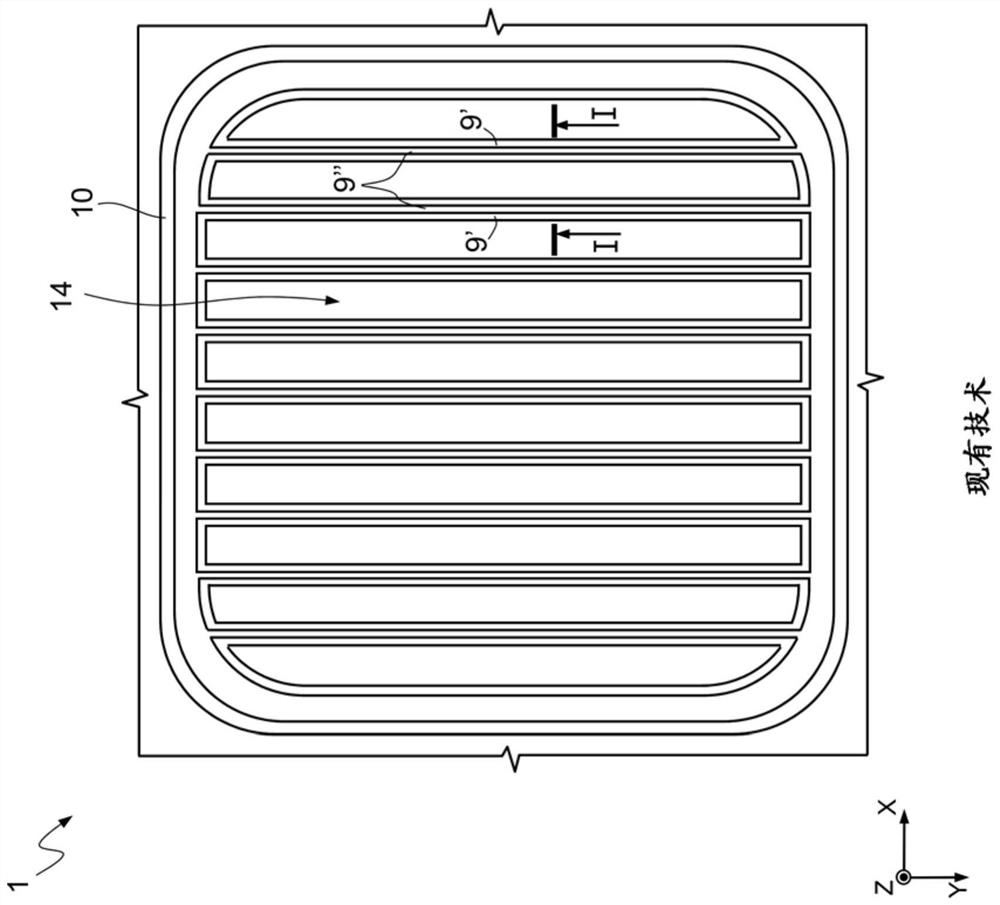

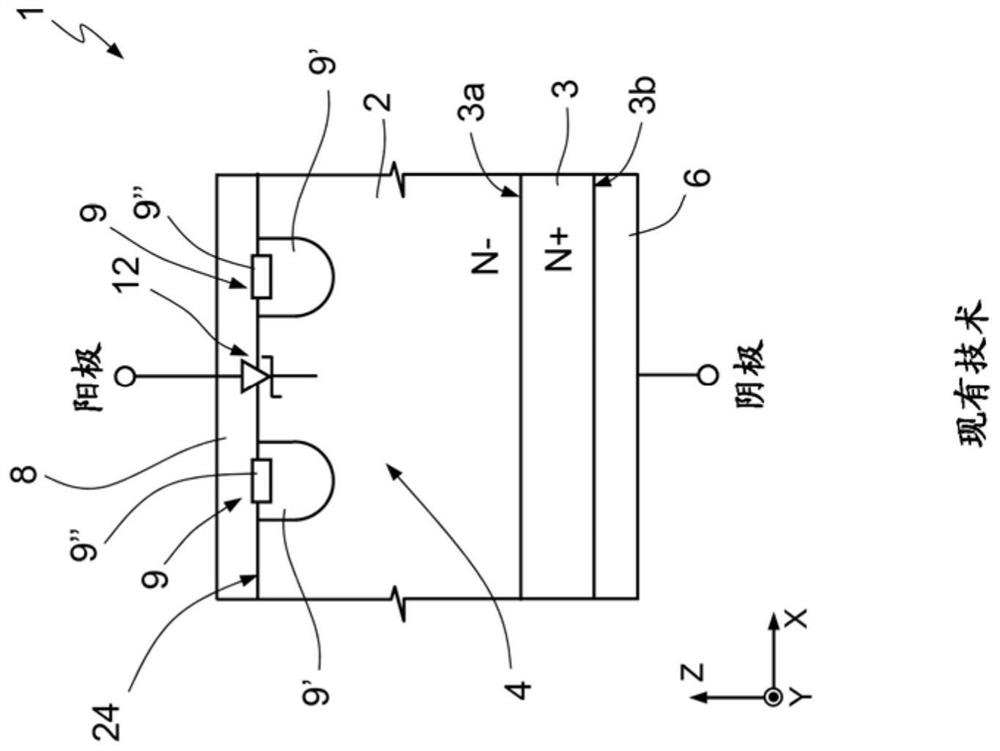

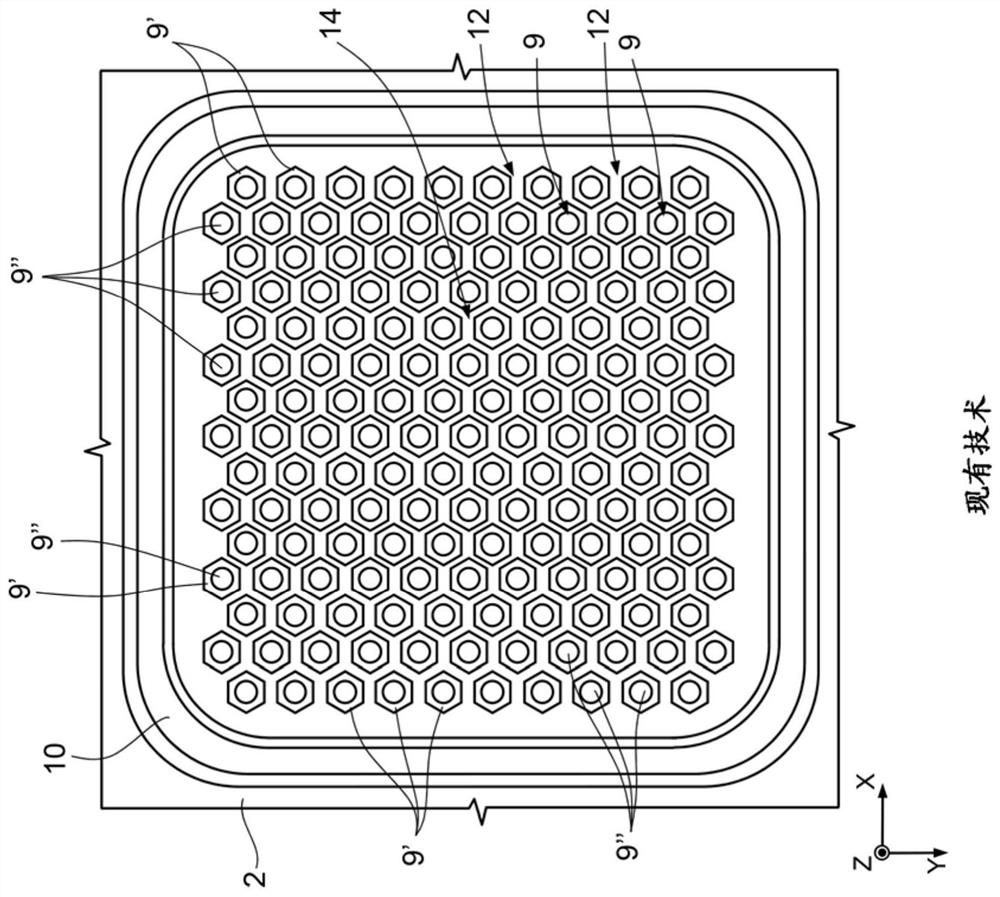

[0024] exist Figure 1A-Figure 3 In the same reference frame of the X, Y, Z axes, Figure 4A A top view (ie, on the XY plane) of a fused PN-Schottky (in particular, MPS) device 30 according to one embodiment of the present invention is shown. Figure 4B shows the same frame of reference along the Figure 4A A transverse sectional view taken along the line IV-IV. In order to improve the Figure 4A understanding that the anode metallization is not shown, but is present, as per the Figure 4B The figure is obvious.

[0025] Figure 4B A transverse cross-section (i.e., on the XZ plane) of is essentially the same as Figure 1B The transverse cross-sectional view is consistent. Similar elements are identified with the same reference numerals and will not be described in detail again.

[0026] However, when considering Figure 4A In the top view of , those skilled in the art can understand that each Schottky diode 32 in the plurality of Schottky diodes 32 includes a correspo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com