Axial tensile test device and method for test piece in constant-temperature erosion environment

A technology of axial tension and test equipment, applied in the direction of measuring equipment, applying stable tension/pressure to test material strength, instruments, etc., can solve the problem of accelerating the corrosion rate of steel bars, reducing the protective effect of concrete on steel bars, and shortening the service life of concrete structures Life and other issues to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

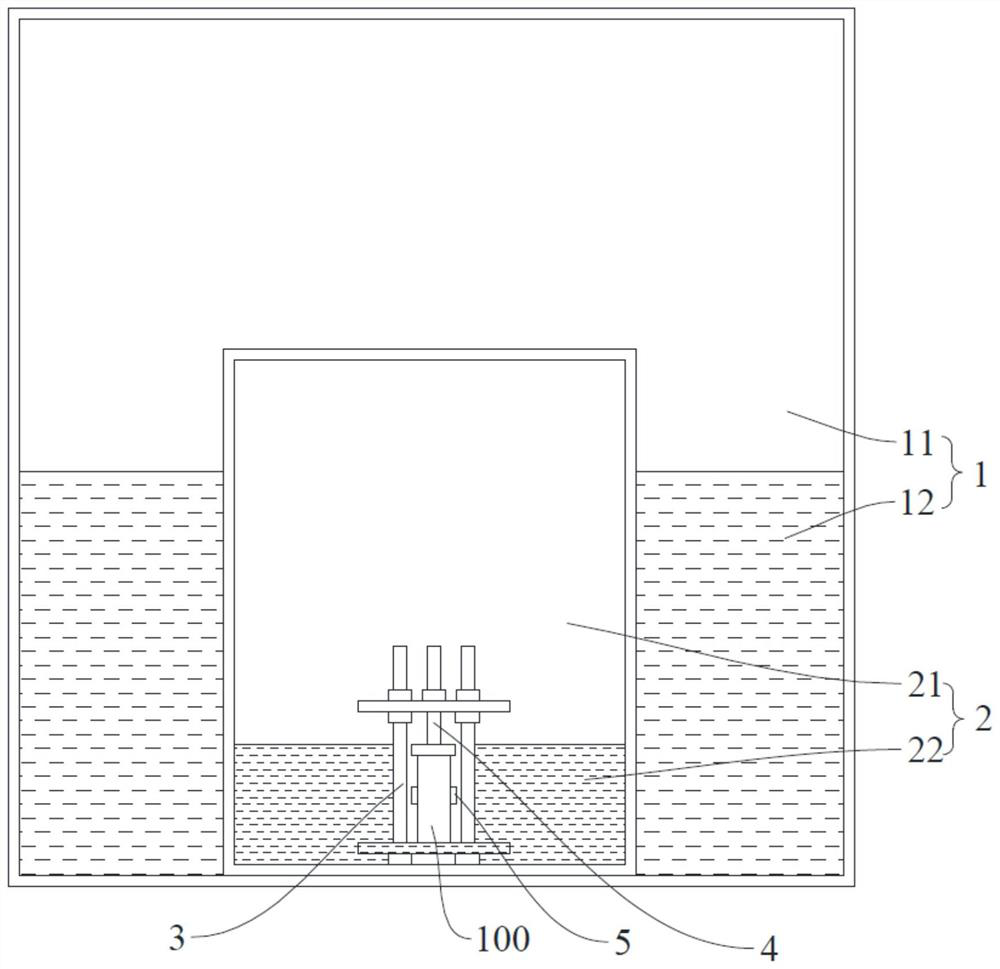

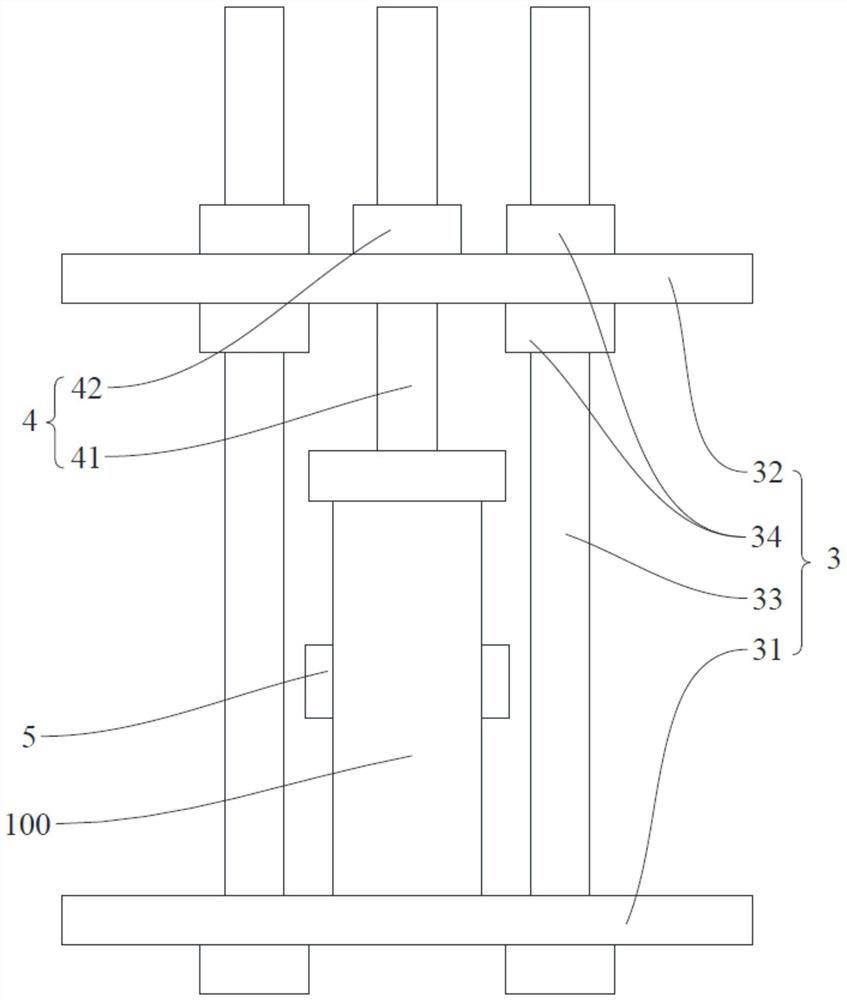

[0073] Refer below Figure 1-Figure 4 An axial tensile test device for a test piece in a constant temperature erosion environment is described in a specific embodiment of the present invention.

[0074] The axial tensile test device of the specimen in the constant temperature erosion environment of this embodiment includes a constant temperature mechanism 1, an erosion mechanism 2, a mounting mechanism 3, a stress loading mechanism 4 and a stress detection mechanism. The constant temperature mechanism 1 is formed with a constant temperature chamber 11, and the temperature of the constant temperature chamber 11 can be set to a preset value. The erosion mechanism 2 is arranged in the constant temperature chamber 11, and the erosion mechanism 2 is formed with an erosion groove 21, and an erosion liquid 22 is arranged in the erosion groove 21.

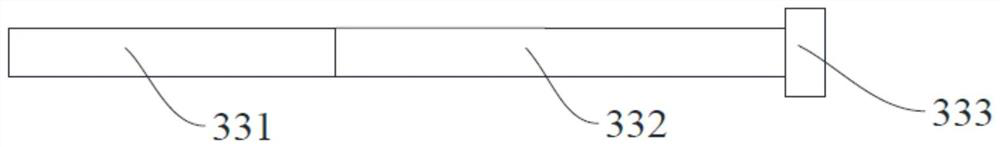

[0075] The installation mechanism 3 is used to fix and install the test piece 100 , the installation mechanism 3 is set in the erosion t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com