Optical fiber monitoring device for debris flow

A monitoring device, debris flow technology, applied in the direction of measuring device, optical device, measuring force, etc., can solve the problems of difficult remote online monitoring, large error of solid source, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

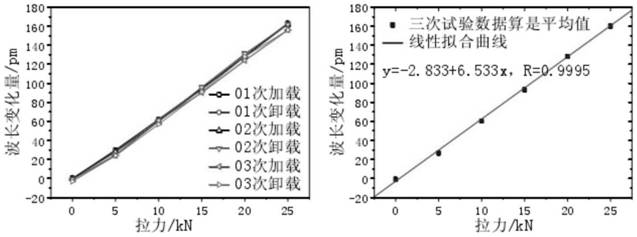

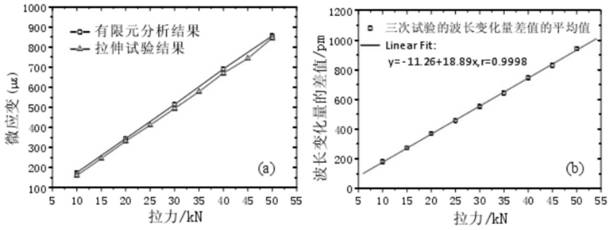

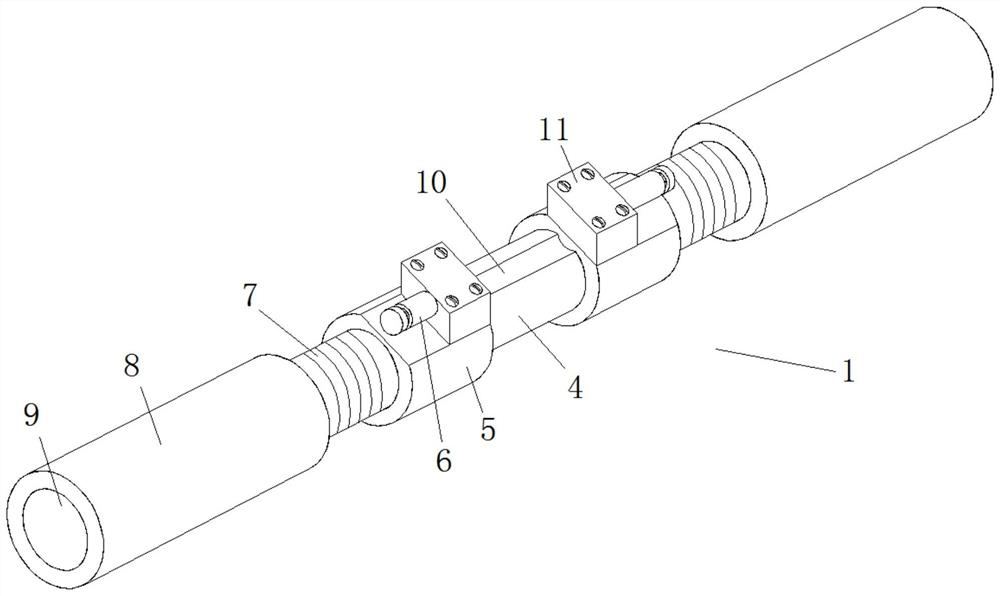

[0033] refer to Figure 1-12 , a fiber optic monitoring device for debris flow, comprising a fiber grating bolt gauge 1, a fiber grating tension sensor 2 and a fiber grating vibration sensor 3, the fiber grating bolt gauge 1 includes a strain measuring body 4, and both ends of the strain measuring body 4 are fixedly connected There is a pigtail outlet protector 5, and one end of the two pigtail outlet protectors 5 away from each other is fixedly connected with a threaded rod 7, the outer thread of the threaded rod 7 is sleeved with a sleeve 8, and the top side of the strain measuring body 4 is provided with a The fiber grating fixing groove 10, the top side of the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com