Automatic processing system used for glass fiber reinforced plastic pipeline

A glass fiber reinforced plastic and pipe technology, applied in applications, household appliances, tubular items, etc., can solve the problems of insufficient uniform winding of glass fiber reinforced plastic, slow heating and drying speed, poor degree of anti-rotation coordination, etc., to achieve high product quality, prolong service life, The effect of avoiding rigid collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

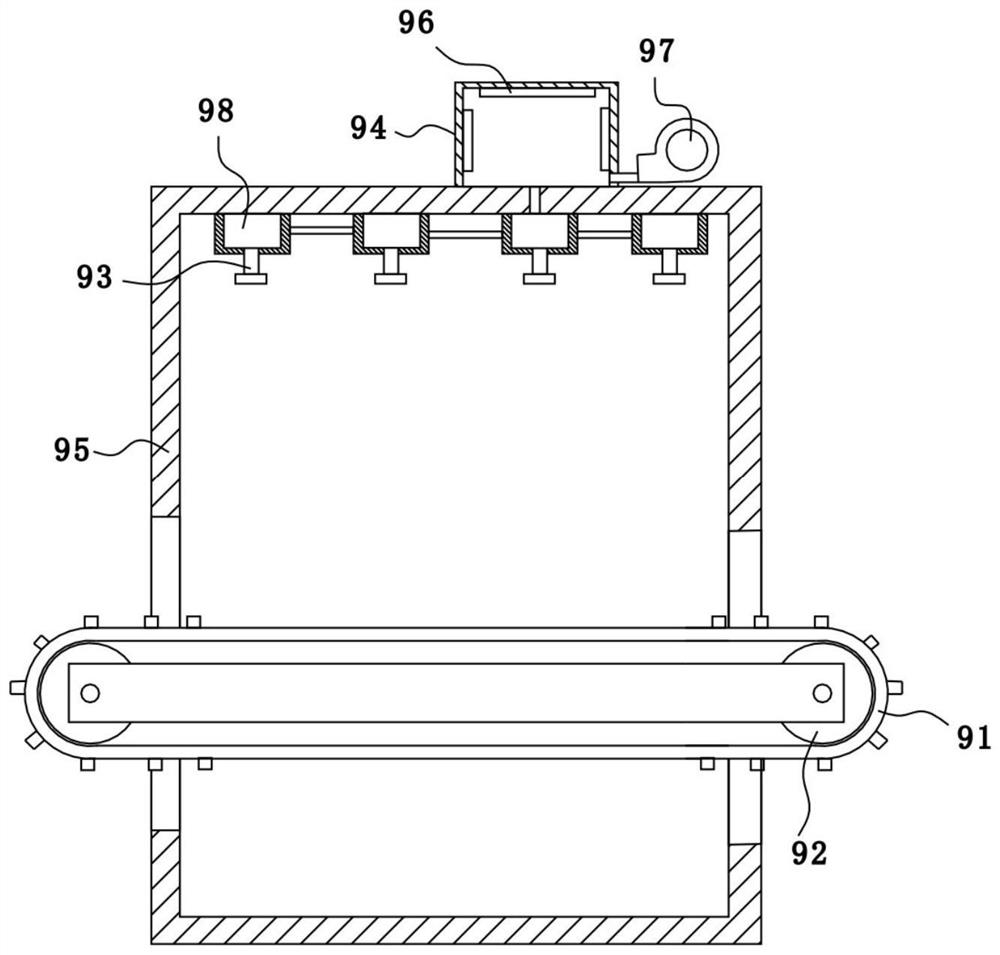

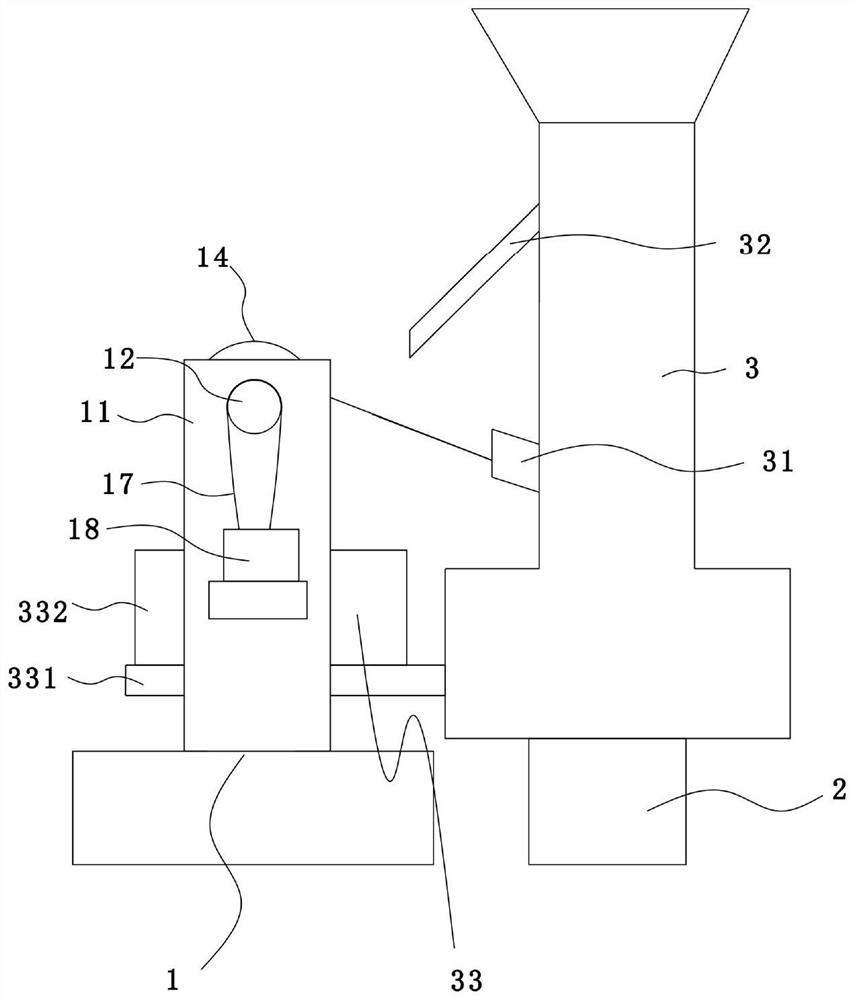

[0028] Such as Figure 1-11 As shown, a system for automatic processing of FRP pipes includes a winding mechanism, a heating mechanism and a feeding frame for transporting materials from the winding mechanism to the heating mechanism; the feeding frame can be a support frame made of metal, and the bottom Rollers are set, and the structure is the prior art, so it will not be repeated; the winding mechanism includes a winding frame 1, a track 2, a trolley 3, a glass fiber silk-discharging mechanism 31 and a sand-discharging mechanism 32 arranged on the trolley, specifically , the winding frame 1 includes a support 11, a transmission shaft 12 rotatably arranged on the support, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com