Micro-channel reaction and mixing device

A microchannel reaction and mixing device technology, applied in the field of microchannels, can solve the problems of S-shaped channel reaction length increase, flow resistance increase, work efficiency decrease, etc., to solve uneven flow distribution, increased turbulence, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

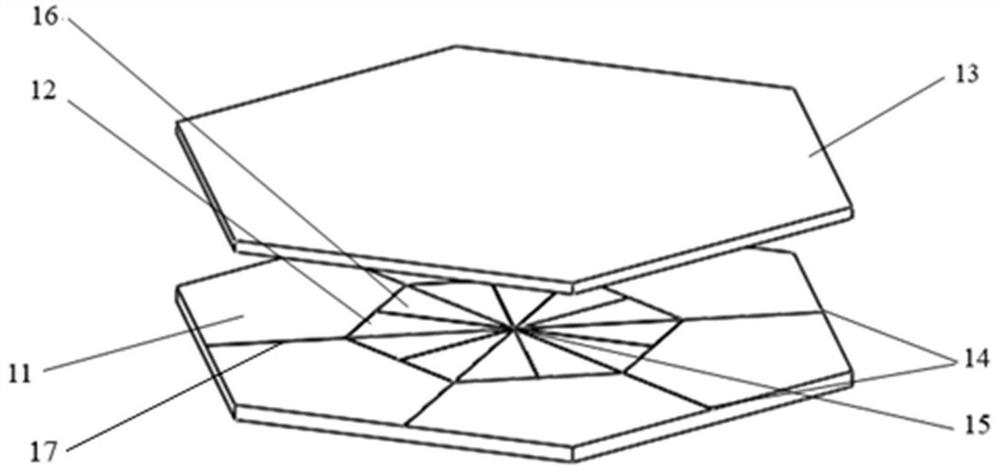

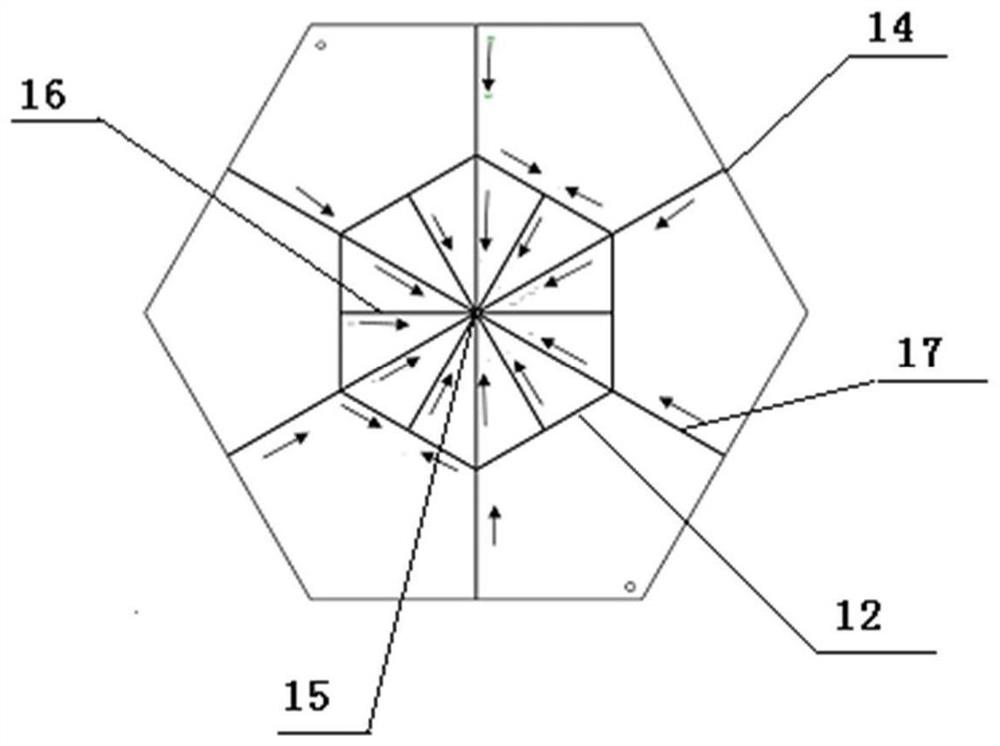

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. These drawings are schematic diagrams to illustrate the basic structure of the present invention. The purpose of the present invention is achieved like this:

[0029] The present invention provides a microchannel reaction and mixing device, the microchannel reaction and mixing device includes a fluid mixing unit, the fluid mixing unit includes a substrate 11; the side wall of the substrate 11 is provided with at least two fluid inlets 14 at different positions; The substrate 11 is provided with a central hole 15 that runs through the substrate 11; the substrate 11 is provided with a microchannel main road 17 corresponding to the number of fluid inlets 14; the substrate 11 is provided with a mixing microchannel 12 and a microchannel branch 16; The inlet 14 communicates with the central hole 15 through the main microchannel 17 ; the main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com