Multi-stage spiral-flow type dust and mist removal device for realizing full-particle-size removal, and dust and mist removal method

A demisting device and technology of full particle size, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of low dust removal and demisting efficiency, short circuit of flue gas, inability to deeply remove droplets, etc. To achieve the effect of good dust removal and fog removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

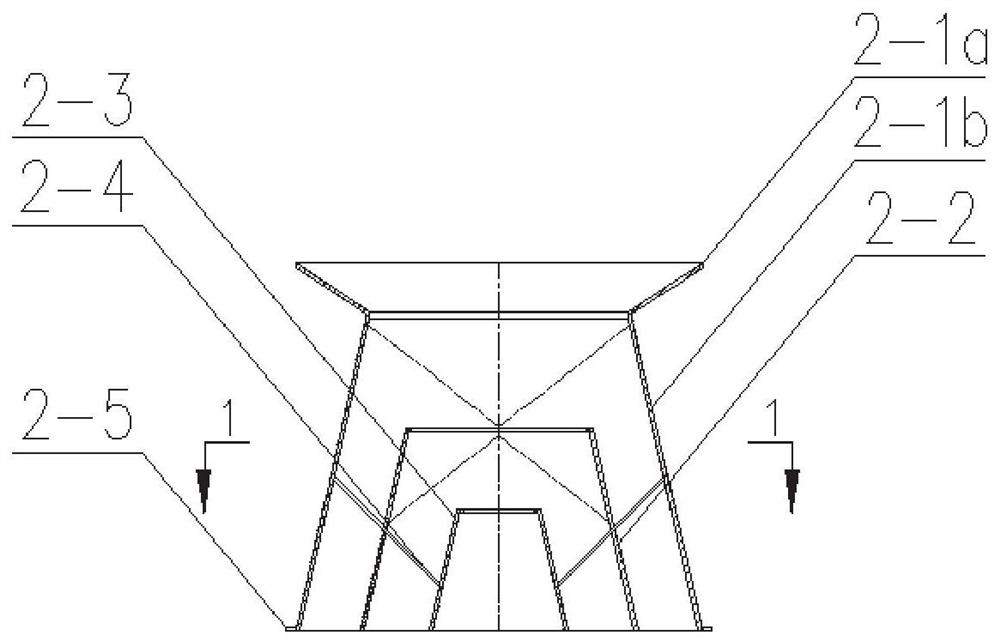

[0070] like figure 1 As shown, the multi-stage cyclone dust removal and mist removal device includes multiple dust removal and mist removal units, and each dust removal and mist removal unit includes at least three stages of dust removal and mist removal units, wherein each stage of dust removal and mist removal units includes an overcurrent Cylinder body, one-stage conventional swirler, three-stage converging device, its structure is as follows figure 2 and image 3 As shown, it includes a first-stage flow-focusing ring, a second-stage flow-focusing ring and a third-stage flow-focusing ring, and the three-stage flow-focusing rings are nested in sequence.

[0071] According to parameters such as flue gas volume, dust removal and mist removal efficiency, etc., three to four layers of dust removal and mist removal units are selected and installed inside the flow-through cylinder 1 .

[0072] The three-stage concentrating rings are all located above the swirler, and they are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com