Boiler pressure regulation prediction control method based on GRU-PID

A technology of predictive control and boiler control, which is applied in the direction of electric fluid pressure control, fluid pressure control, and controllers with specific characteristics, etc. It can solve problems such as unsatisfactory industrial production, low boiler control accuracy, and control overshoot. , to achieve good prediction performance, strong excavation ability, and improve control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

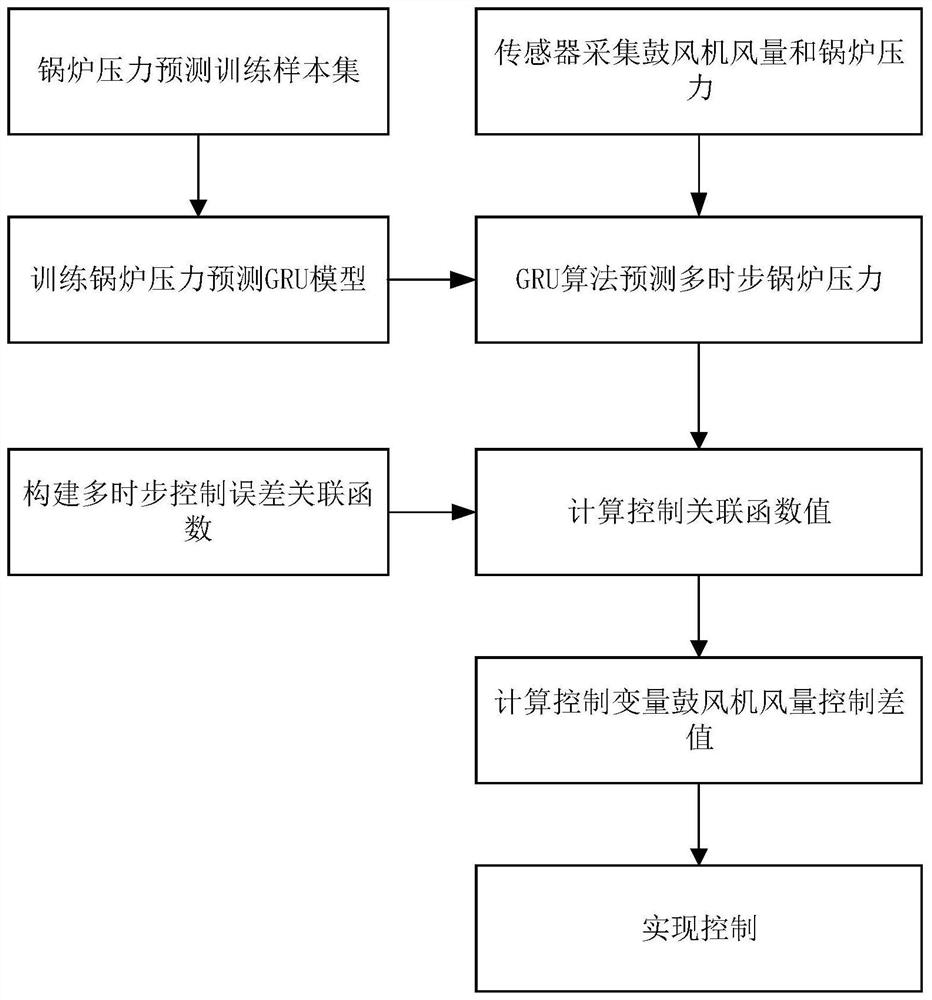

[0057] A predictive control method for boiler pressure regulation based on GRU-PID, such as figure 1 Shown is the framework diagram of the boiler pressure regulation predictive control method based on GRU-PID, the specific steps are as follows,

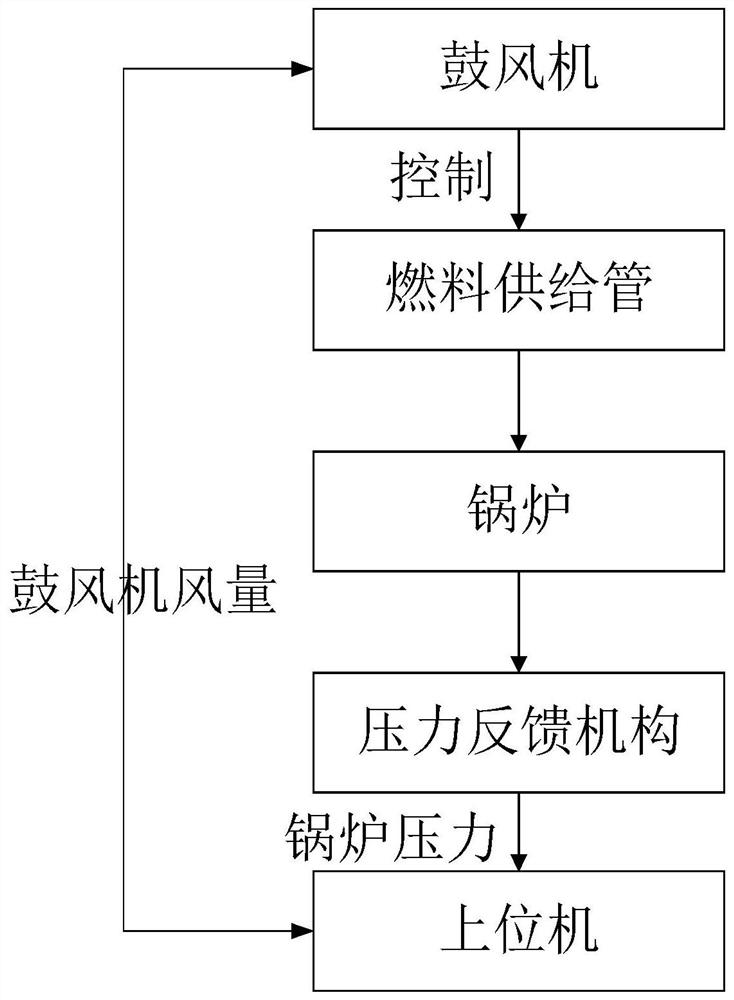

[0058] Step 1: Establish boiler pressure regulation control system, such as figure 2 Shown is a schematic diagram of the boiler pressure regulation control system, which is mainly composed of a blower with adjustable air volume, a fuel inlet pipe, a combustion chamber, a boiler chamber, a pressure feedback mechanism, and a steam output pipe. Among them, the pressure feedback mechanism generates the pressure value through the amplifier based on the electrical signal of the piezoelectric sensor, obtains the pressure value P of the boiler in real time, and uploads the pressure value to the host computer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com