Quantum dot optical fiber microbend sensor with position detection function

A technology of microbend sensors and quantum dots, which is applied in the direction of instruments, measuring devices, and optical devices, etc., can solve the problems of multi-point pressure detection that cannot measure the specific position of the microbend of the optical fiber, reduce the types of use, and improve the efficiency of fluorescence return transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

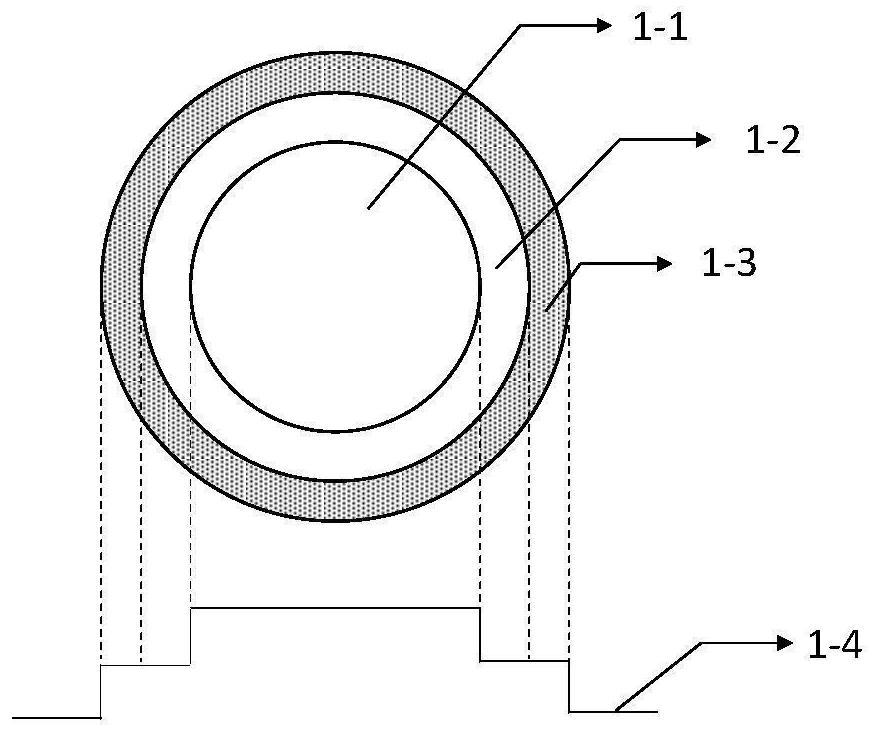

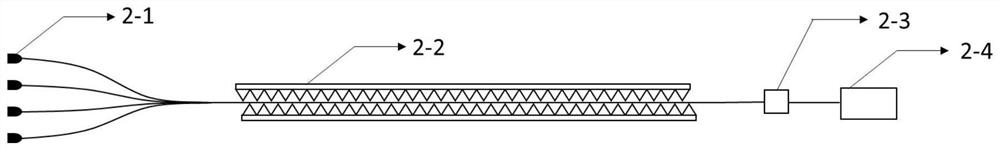

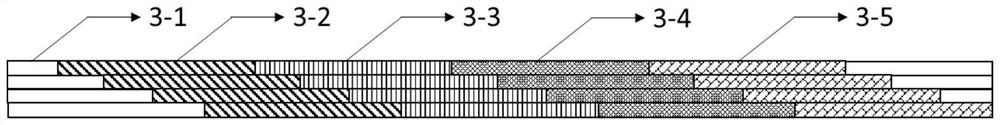

[0023] figure 1 It is the structural diagram of the sensitive optical fiber used, including the fiber core 1-1, the fluorinated polymer cladding 1-2, and the quantum dot mixed fluorinated polymer coating 1-3. The refractive index profile is the core n 1 , cladding n 2 with quantum dot coating n 3 , air 1-4 refractive index n 4 , where n 1 ﹥n 2 =n 3 ﹥n 4 . figure 2 It is an overall structure of a plurality of optical fiber groups, including an ultraviolet light source 2-1, a deformer 2-2, an optical fiber combiner 2-3, and a spectrometer 2-4. image 3 It is the arrangement of the detection group composed of multiple detection optical fibers, and it shows the different materials coated in different sections, among which 3-1 is a white optical fiber without quantum dot coating, 3-2 is coated with quantum dot 1, 3-3 Coated quantum dot 2, 3-4 quantum dot 3, 3-5 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com