A winding device for a tape-shaped winding photoelectric transmission composite cable

A technology of photoelectric transmission and winding device, which is applied in the directions of transportation and packaging, conveying filamentous materials, and thin material processing, etc., which can solve the problems of low production efficiency, high labor intensity, and poor winding stability of spiral cables, and achieve Fast and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiment and accompanying drawing, set forth more details in the following description so as to fully understand the present invention, but the present invention can be implemented in many other modes different from this description obviously, Those skilled in the art can make similar promotions and deductions based on actual application situations without violating the connotation of the present invention, so the content of this specific embodiment should not limit the protection scope of the present invention.

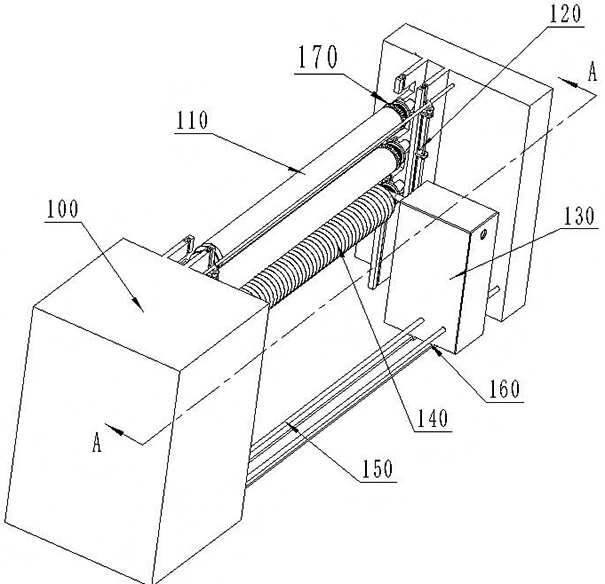

[0025] Such as figure 1 As shown, a tape-shaped winding type photoelectric transmission composite cable winding device includes: a frame 100, a winding rod 110, an elastic clamping head 170, a feeding mechanism 120, a moving mechanism 130, a screw shaft 150, and a light rod shaft 160.

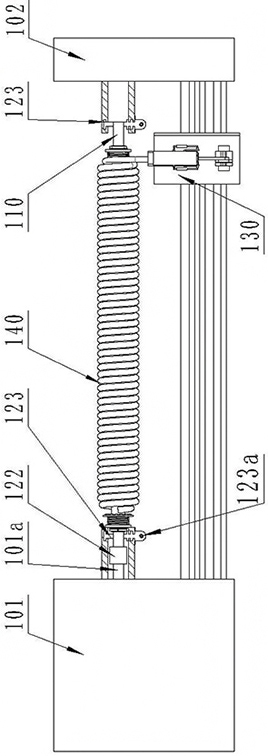

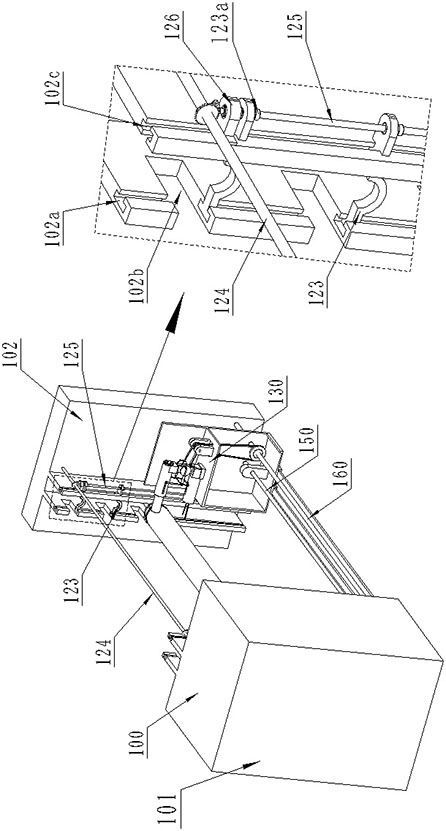

[0026] Such as figure 2 , 3 , 4, the frame 100 includes a power box 101 on the left sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com