A continuous winding device for textile fabrics

A textile cloth and winding device technology, applied in the direction of thin material processing, winding strips, transportation and packaging, etc., can solve the problems of inconvenient maintenance and use, increase the frequency of equipment maintenance, and more yarn drop, etc., to achieve Reduce yarn shedding, facilitate continuous winding, and improve winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

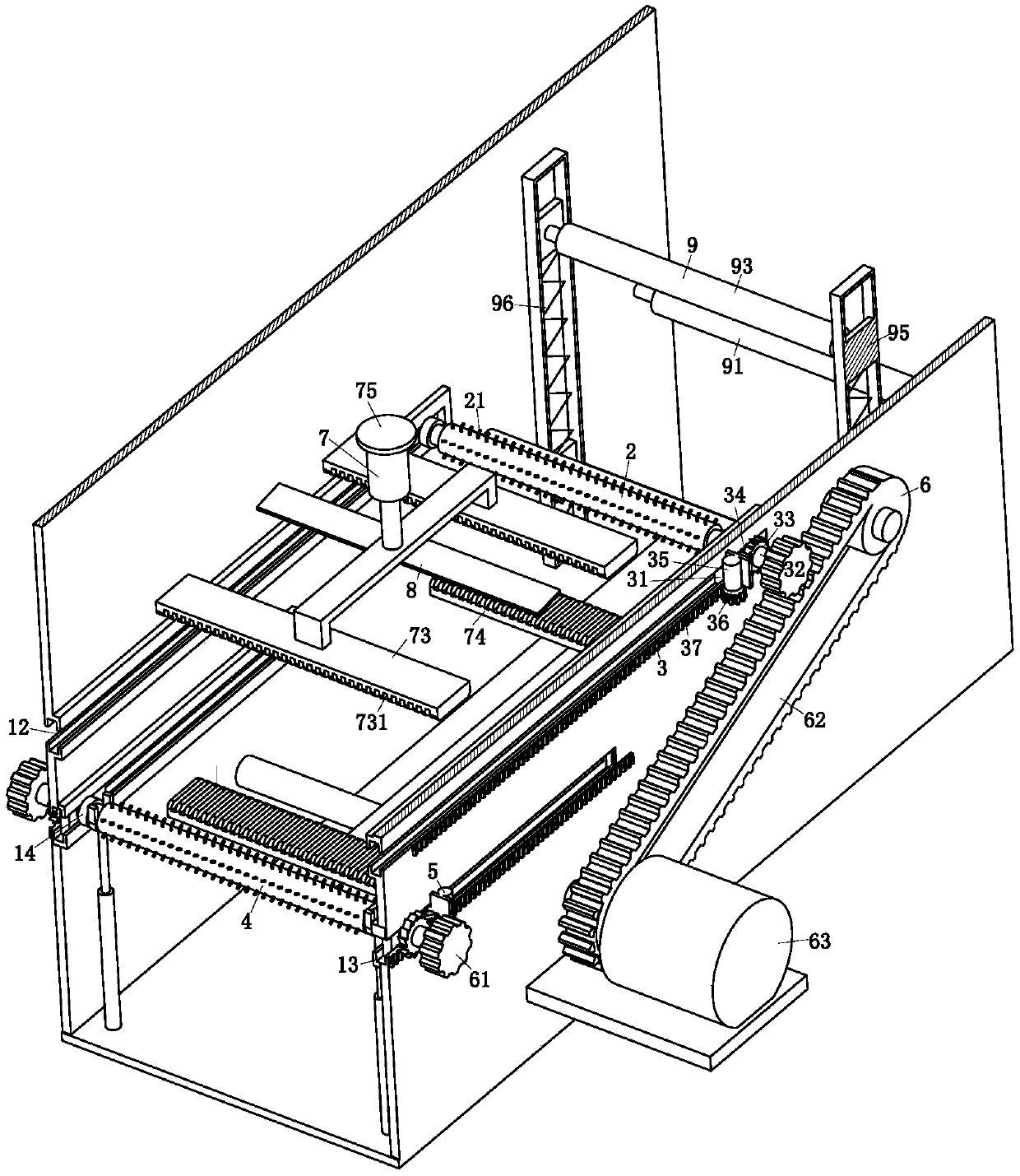

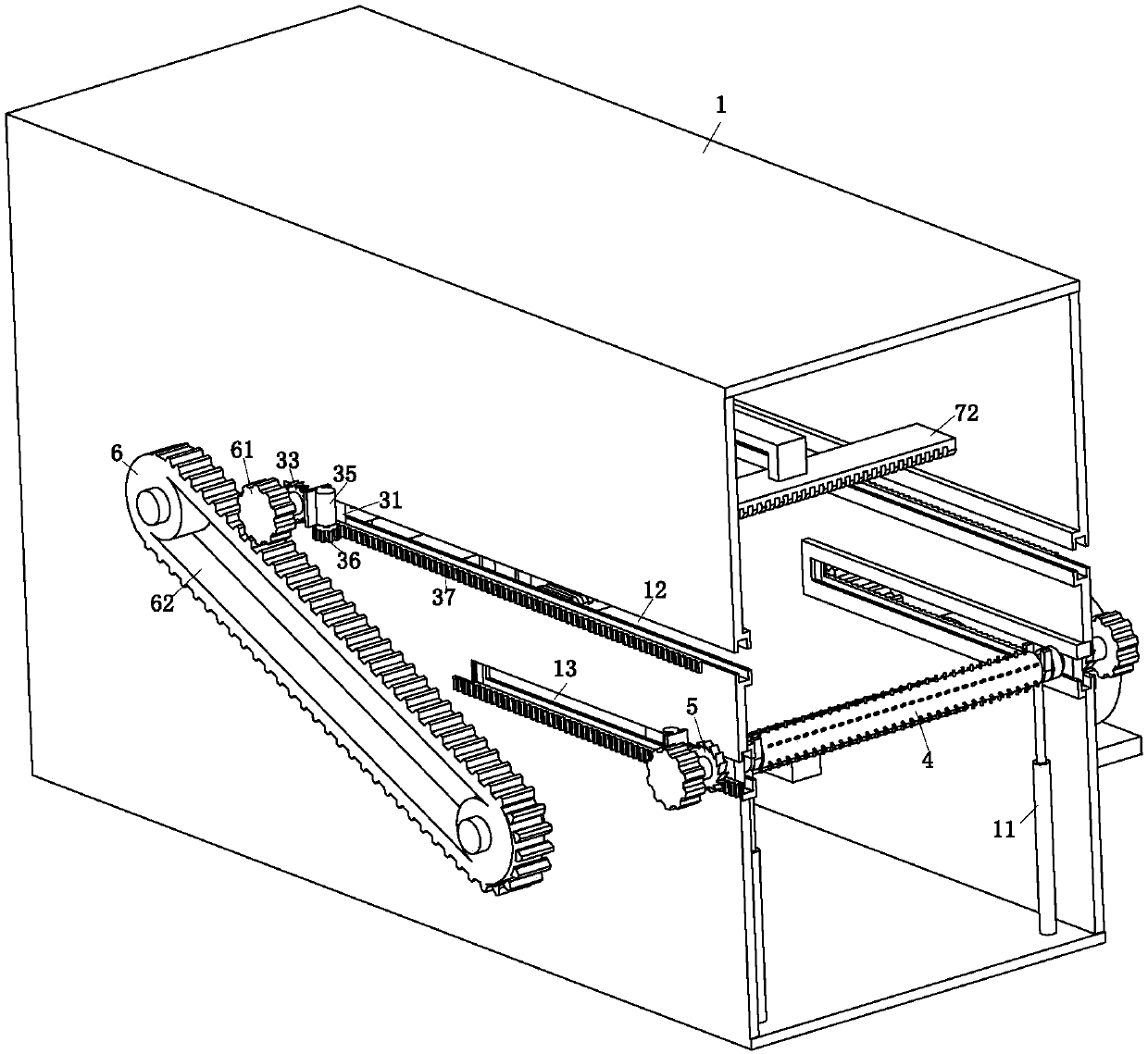

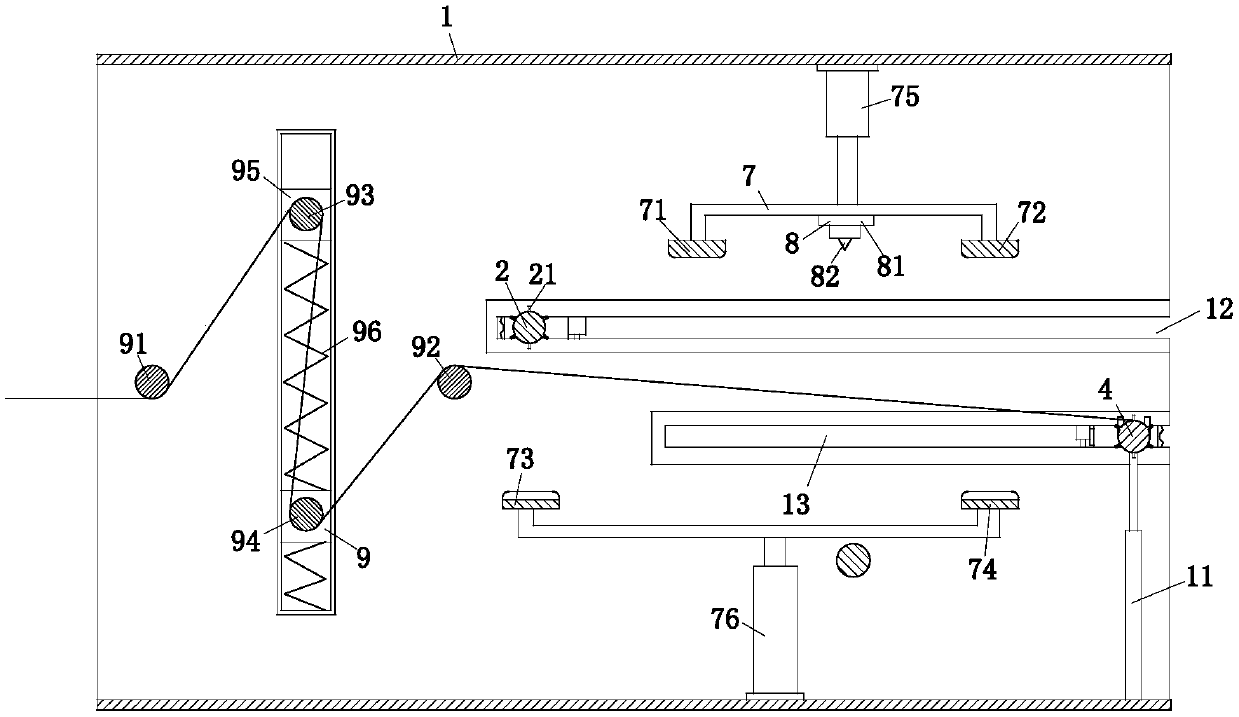

[0030] As an embodiment of the present invention, the upper connecting module 3 includes a slider 31, a connecting shaft 32, a ratchet 33, a pawl 34, a sliding motor 35, a sliding gear 36 and a sliding rack 37, and the slider 31 is installed In the upper chute 12 and can slide along the chute, the connecting shaft 32 is installed on the slide block 31 through a bearing, one end of the connecting shaft 32 is connected with the upper reel 2 through a coupling 14, and the other end of the connecting shaft 32 Pass through the body 1; the ratchet 33 is installed on the connecting shaft 32, and the ratchet 34 used in conjunction with the ratchet 33 is installed on the slider 31. The ratchet 33 and the ratchet 34 can prevent the upper reel 2 from rotating in reverse; the sliding The motor 35 is installed on the slider 31, the sliding gear 36 is installed on the sliding motor 35, and the sliding rack 37 is arranged in parallel on the side of the upper chute 12, and the sliding gear 36 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com