Preparation method for rapidly connecting short oblique belt prepregs into continuous oblique belt prepreg

A quick connection and prepreg technology, applied in the direction of coating, etc., can solve the problems of different lengths of overlapping parts, uneven sides of prepreg, low production efficiency, etc., to achieve automatic mechanical production and continuous winding , The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

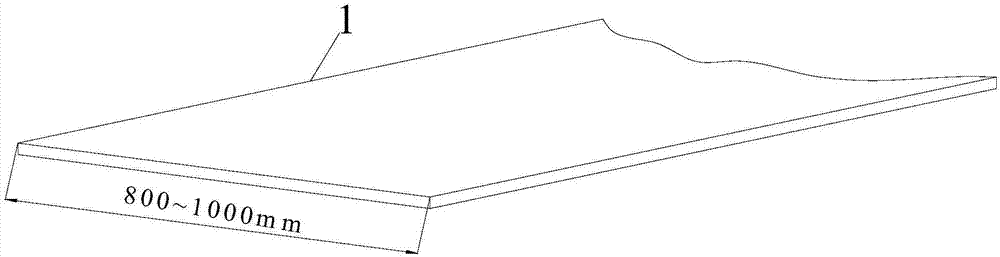

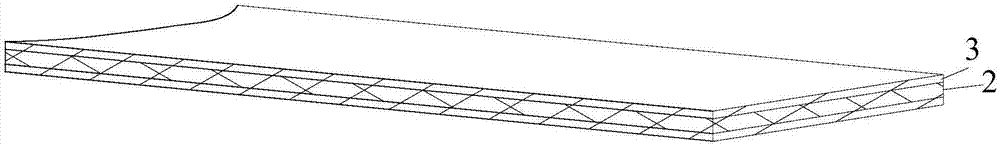

[0027] Step 1: Put a fabric prepreg with a width of 800mm (such as figure 1 Shown) An automatic cutting device is used to cut diagonal prepregs with a width of 20mm, an angle of 30°, and a length of 1600mm along the width direction, such as figure 2 Shown

[0028] Step 2: The inclined belt prepreg with a width of 20mm, an angle of 30°, and a length of 1600mm is automatically transported to the overlapping device through the conveyor. The ends of the two inclined belt prepregs to be overlapped are overlapped by 10mm and are short The two sides of the diagonal belt prepreg are automatically kept in alignment, such as image 3 Shown

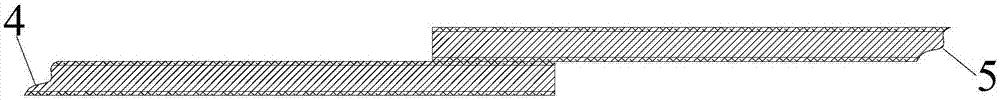

[0029] Step 3: The overlapping 10mm part of the two short diagonal belt prepregs is quickly punched by an anti-sticking clamping device with a temperature of 60°C and a pressure of 50N, and the overlapping 10mm part of the short diagonal belt prepreg is pressed together, such as Figure 4 Shown.

[0030] Step 4: The overlapping 10mm part of the two short ...

Embodiment 2

[0034] This example is to use the automatic beveling equipment to cut the fabric prepreg with a width of 1000mm along the width direction into a diagonal belt with a width of 100mm, an angle of 90°, and a length of 1000mm according to the set tape width and angle. The immersion material is automatically transferred to the overlap device. The two short diagonal belt prepregs are overlapped end to end according to the overlap length of 100mm, and the two sides of the short diagonal belt prepreg are kept aligned, and then automatically transferred to On the connecting device, the overlapping parts of the two short diagonal belt prepregs are connected together by means of pressure, heating and sewing, so as to obtain a continuous diagonal belt prepreg with sufficient tensile strength. Finally, the continuous inclined belt prepreg is automatically transferred to the automatic winding device through the automatic belt conveyor system.

[0035] Step 1: Put a fabric prepreg with a width ...

Embodiment 3

[0042] Step 1: Put a fabric prepreg with a width of 900mm (such as figure 1 Shown) An automatic cutting device is used to cut diagonal prepregs with a width of 55mm, an angle of 60°, and a length of 1039mm along the width direction, such as figure 2 Shown

[0043] Step 2: The inclined belt prepreg with 55mm, 60° angle and 1039mm length is automatically transported to the overlapping device through the conveying device, and the ends of the two inclined belt prepregs to be overlapped are overlapped by 55mm with a short diagonal The two sides with prepreg are automatically kept in alignment, such as image 3 Shown

[0044] Step 3: The overlapping 55mm part of the two short diagonal belt prepregs is quickly punched by the anti-sticking clamping device with a temperature of 90℃ and a pressure of 175N, and the overlapping 55mm part of the short diagonal belt prepreg is pressed and attached, such as Figure 4 Shown.

[0045] Step 4: The overlapping 55mm part of the two short diagonal prepr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com