Express package air bubble film packaging equipment

A bubble film and wrapping technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of difficult cutting and heat sealing of air bubble film, difficult cutting of two layers of air bubble film, and difficulty of heat sealing of two layers of air bubble film, etc. Achieve the effects of high packing efficiency, increased strength, and firm hot pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

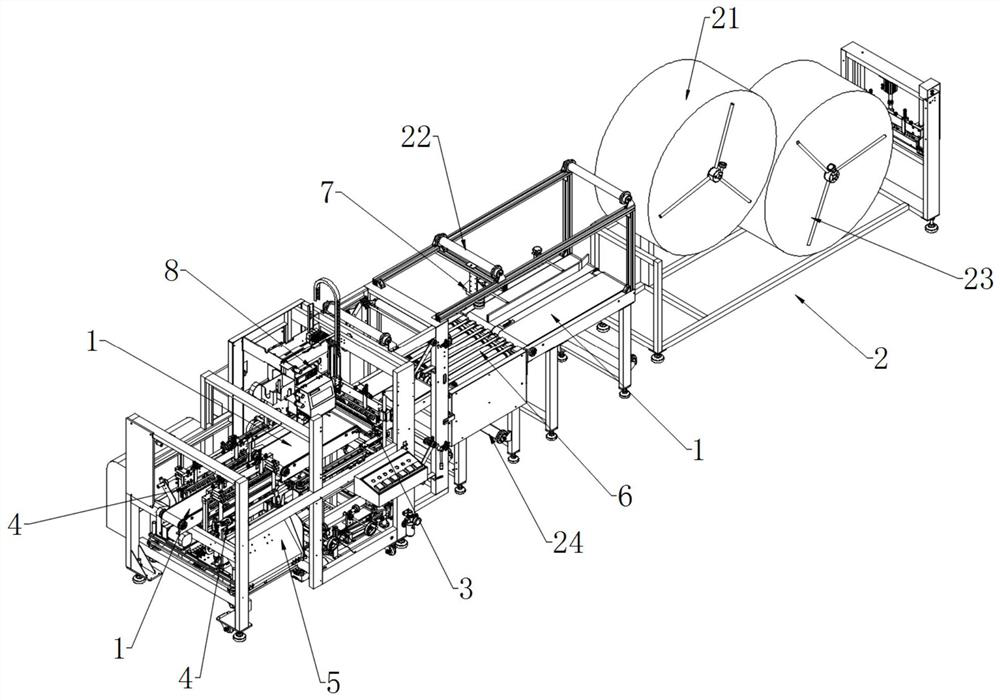

[0029] refer to Figure 1-11 , a bubble film packaging equipment for express parcels, which is used for packaging express parcels. The packaging is covered with air bubble film, which can be cut and heat-sealed with a thick air bubble film with air bubbles in the interlayer. The packaging is convenient and fast. Express parcel air bubble film packaging equipment includes conveying device 1, air bubble film feeding device 2, horizontal sealing and cutting device 3 and vertical sealing and cutting device 4, and the air bubble film feeding device 2, horizontal sealing and cutting device 3 and longitudinal sealing and cutting device 4 are arranged in turn In the conveying direction of the device 1; the conveying device 1 conveys the express package to be packaged, and the air bubble film feeding device 2 sends the air bubble film to the upper and lower sides of the express package to be packaged on the conveying device 1, and the express package to be packaged During the package d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com