Double-shot molding technology based on self-cooling type injection molding machine

A two-color injection molding and two-color injection molding machine technology, which is applied in the field of two-color injection molding technology based on self-cooling injection molding machines, can solve the problems of unsatisfactory heat dissipation, low molding efficiency, and low molding efficiency, so as to accelerate heat loss and promote rapid Effect of cooling forming and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

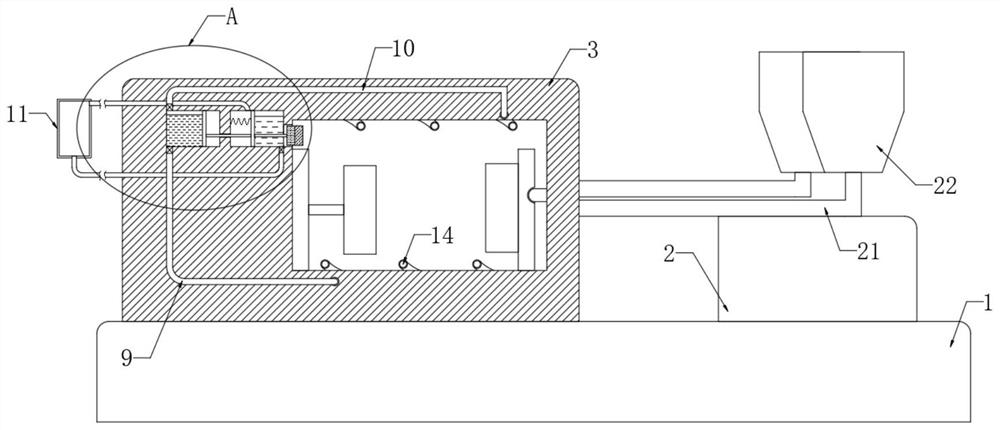

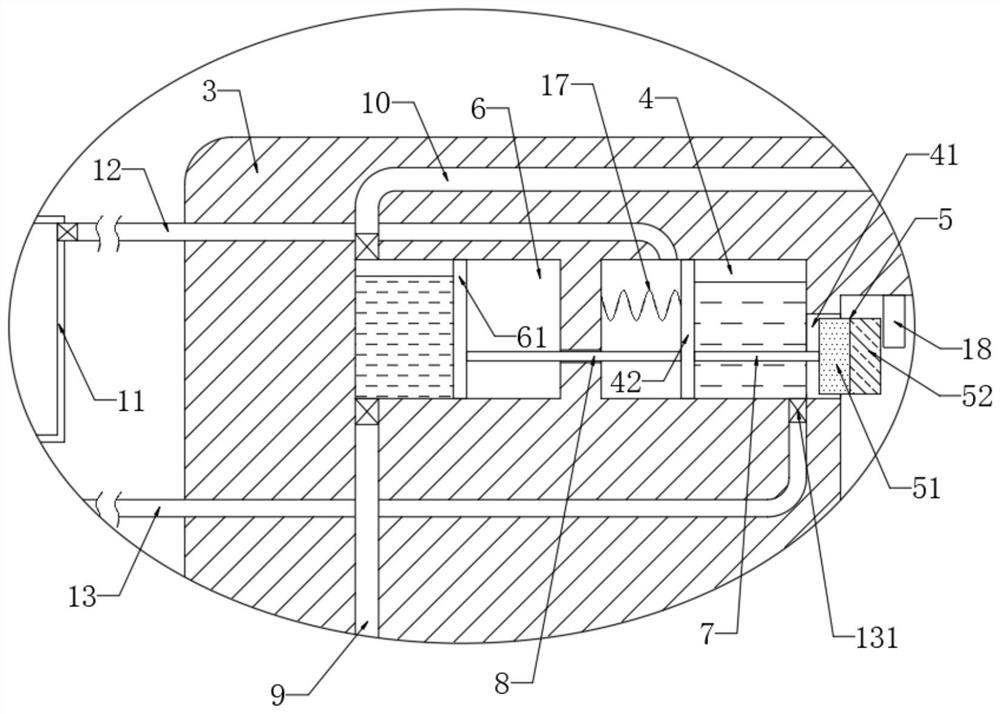

[0028] refer to Figure 1-2 , a two-color injection molding process based on a self-cooling injection molding machine, including the following steps:

[0029] S1, feeding, put the dried two raw materials into the two hoppers of the two-color injection molding machine respectively;

[0030] S2, material feeding, start the two-color injection molding machine, the two feeding cylinders in the two-color injection molding machine respectively convey two kinds of raw materials, and the feeding cylinders heat the raw materials to a molten state at the same time;

[0031] S3, injection, control the output of molten raw materials through the nozzle in the two-color injection molding machine, and inject the two raw materials into different molding grooves in the mold in turn;

[0032] S4, cooling molding, the cooling water channel in the two-color injection molding machine continuously dissipates the internal heat, and the molten raw materials in the mold are gradually cooled and forme...

Embodiment 2

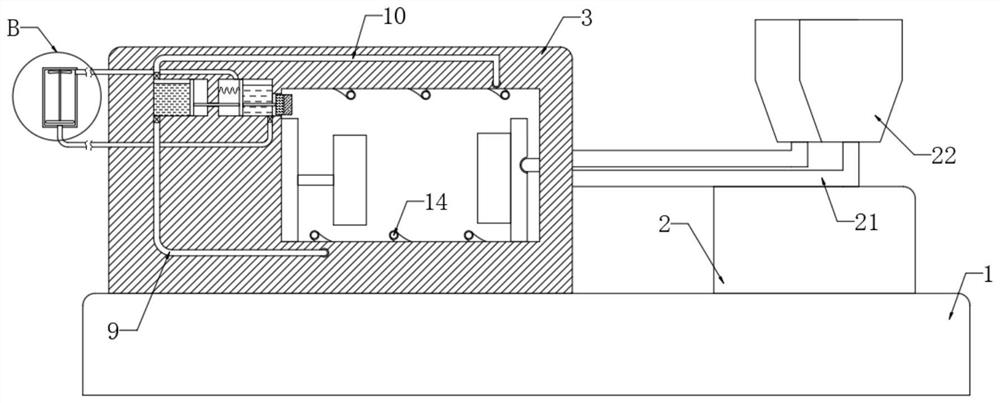

[0048] refer to Figure 3-4 , different from Embodiment 1, the inner top of the liquid storage cylinder 11 is rotatably connected with a steam turbine 15, and the blades of the steam turbine 15 can be made into a wind cup shape, so that the evaporated liquid flow blown in can push the steam turbine 15 Rotate, and the lower end of the steam wheel 15 is fixedly connected with a spoiler 16 coaxially.

[0049] In this embodiment, when the vaporized evaporating liquid flows into the liquid storage cylinder 11 along the one-way inlet pipe 12, it can blow the steam turbine 15 to rotate, and drive the spoiler 16 coaxially arranged with the steam turbine 15 to rotate together, which can The evaporating liquid in the liquid storage cylinder 11 is stirred to quickly dissipate the heat contained in the evaporating liquid through the liquid storage cylinder 11 with good heat conduction, thereby improving the working efficiency of the device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com