Novel machining turnover device

A technology of machining and turning device, which is applied in the field of machining, can solve the problems of inability to realize large-angle turning, inconvenient machining of workpieces, and easy slippage of workpieces, and achieves stable fixation, easy machining, and enhanced clamping strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

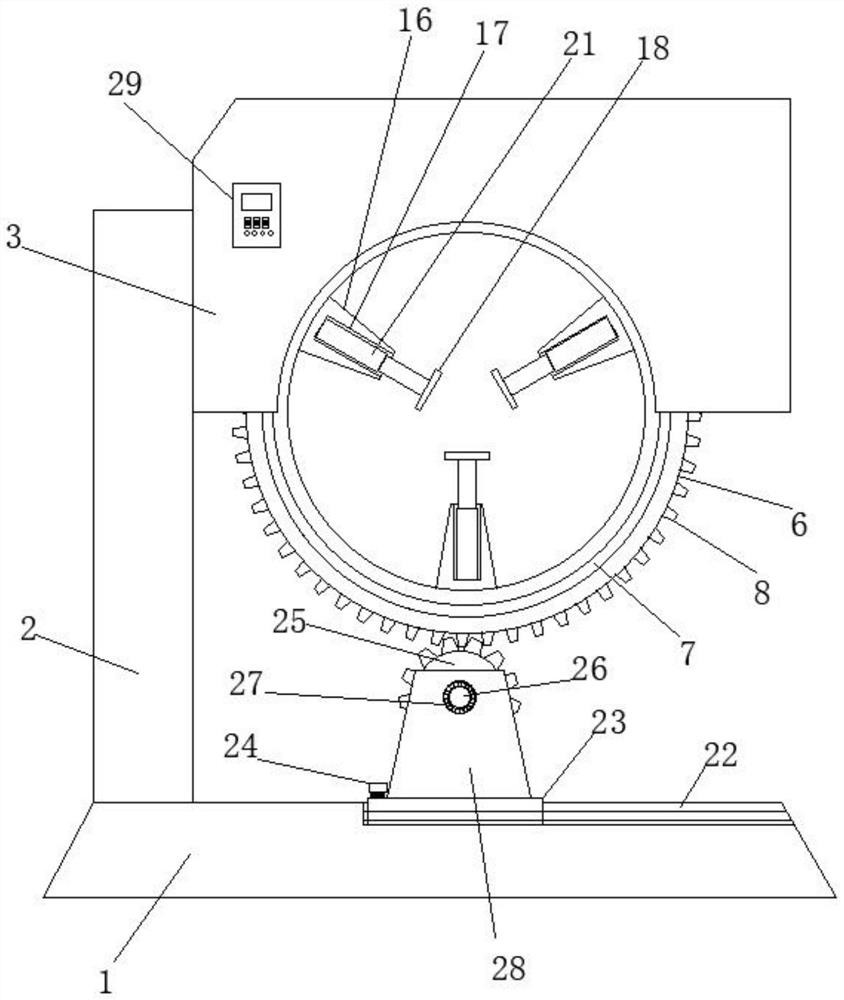

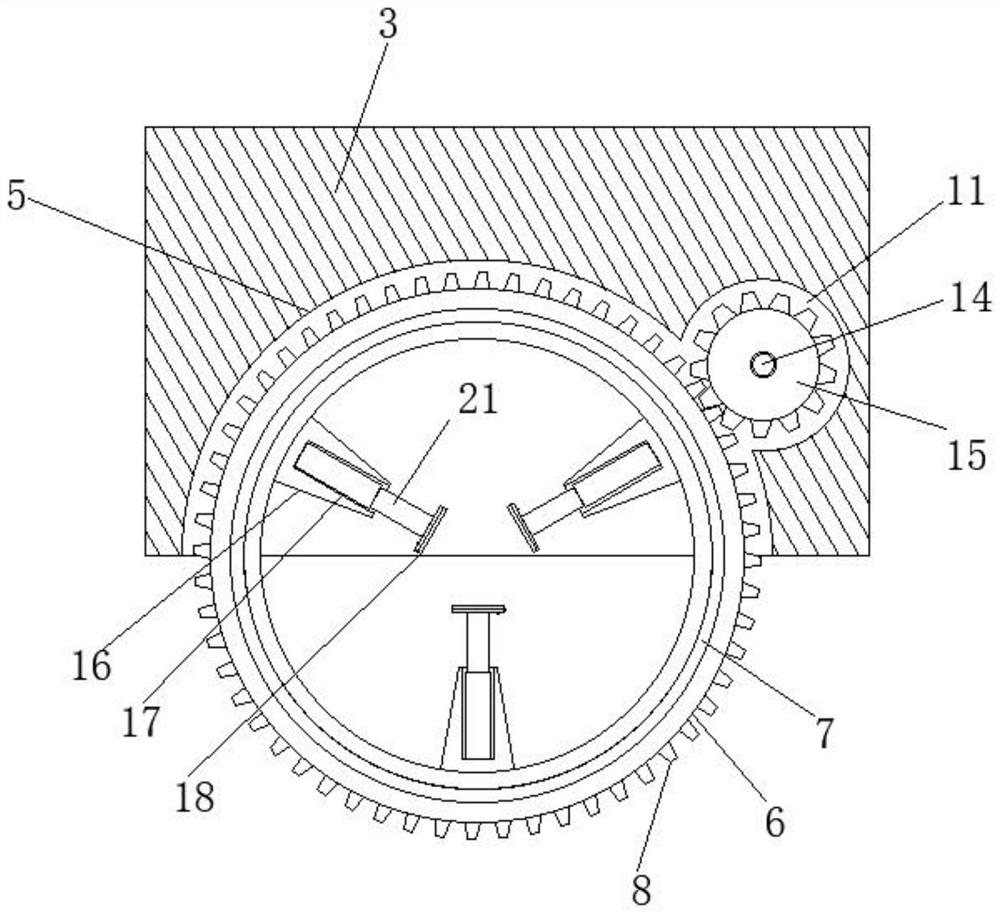

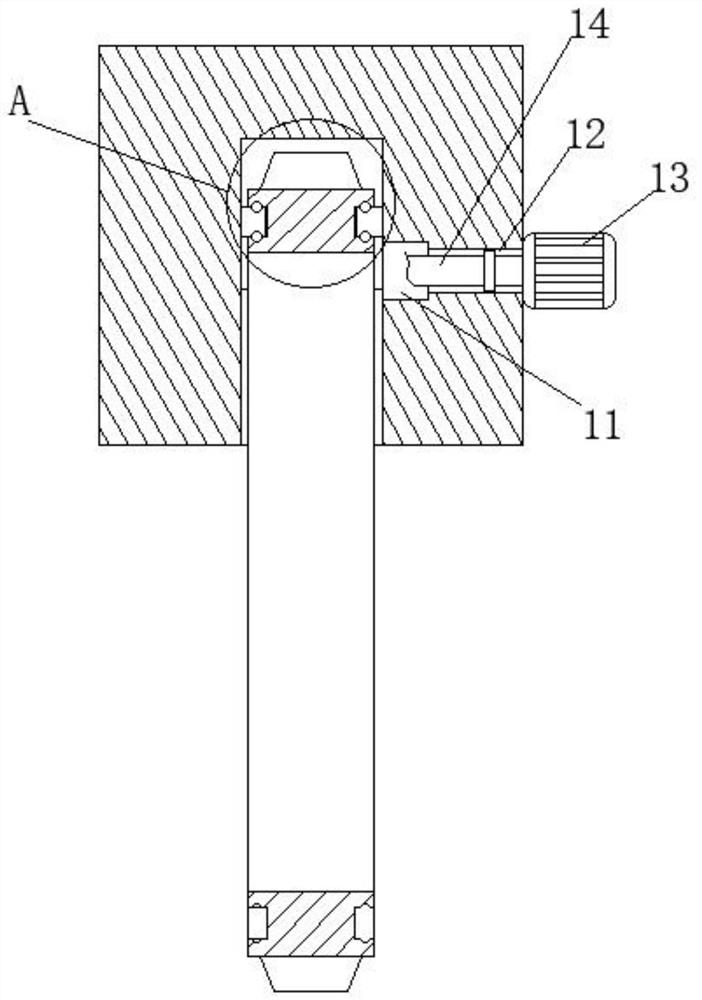

[0032] Attached below Figure 1-7 The present invention is further described with embodiment:

[0033] A new turning device for mechanical processing, comprising a base 1 and a ring 6, a support frame 2 is provided on one side of the top end of the base 1, and a mounting plate 3 is provided on the top end of one side of the support frame 2, and the mounting plate 3 The middle part of the bottom end is sunken upwards to form a mounting groove 5, and the circular ring 6 is rotatably installed inside the mounting groove 5, and both side walls of the circular ring 6 are provided with a ring-shaped limiting groove 7, so that The outer circumferential wall of the ring 6 is provided with outer teeth 8 distributed in a ring, and the inner walls of both sides of the installation groove 5 are equipped with a limit block 9 that is slidably connected with the limit groove 7, and the inside of the installation plate 3 is opened. There is a side groove 11, and one side outer wall of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com