A planetary gear carrier clamp

A planetary gear carrier and fixture technology, which is applied in the field of tooling and fixtures, can solve the problems of poor clamping stability, blocking interference of machining tools, and small contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0035] In the present invention, it should be noted that the direction close to the axis of the mandrel is "inner", and the direction away from the axis of the mandrel is "outer".

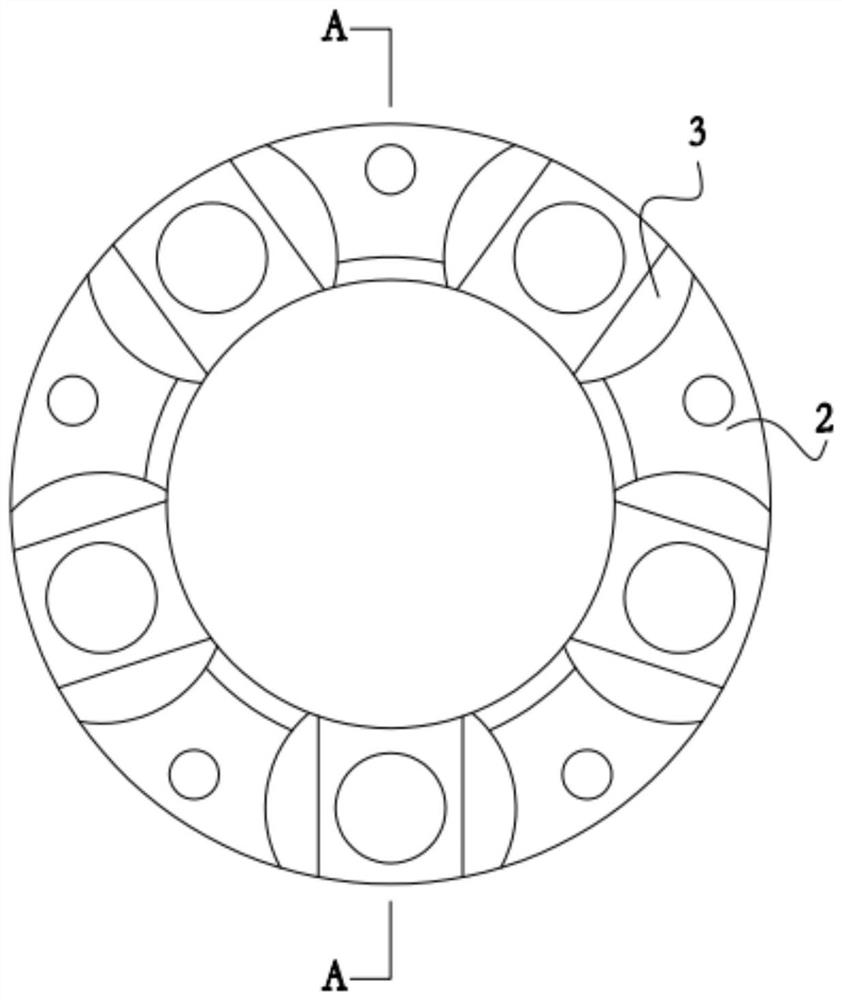

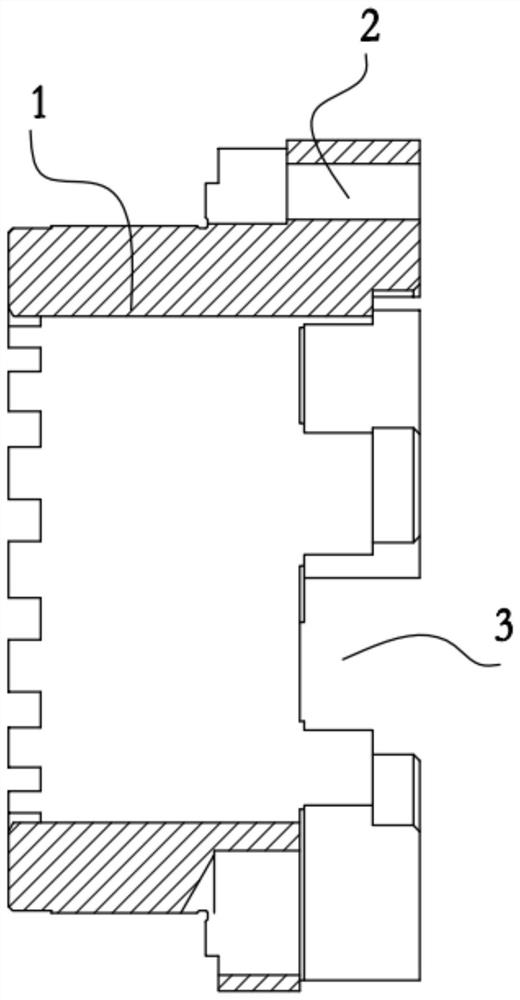

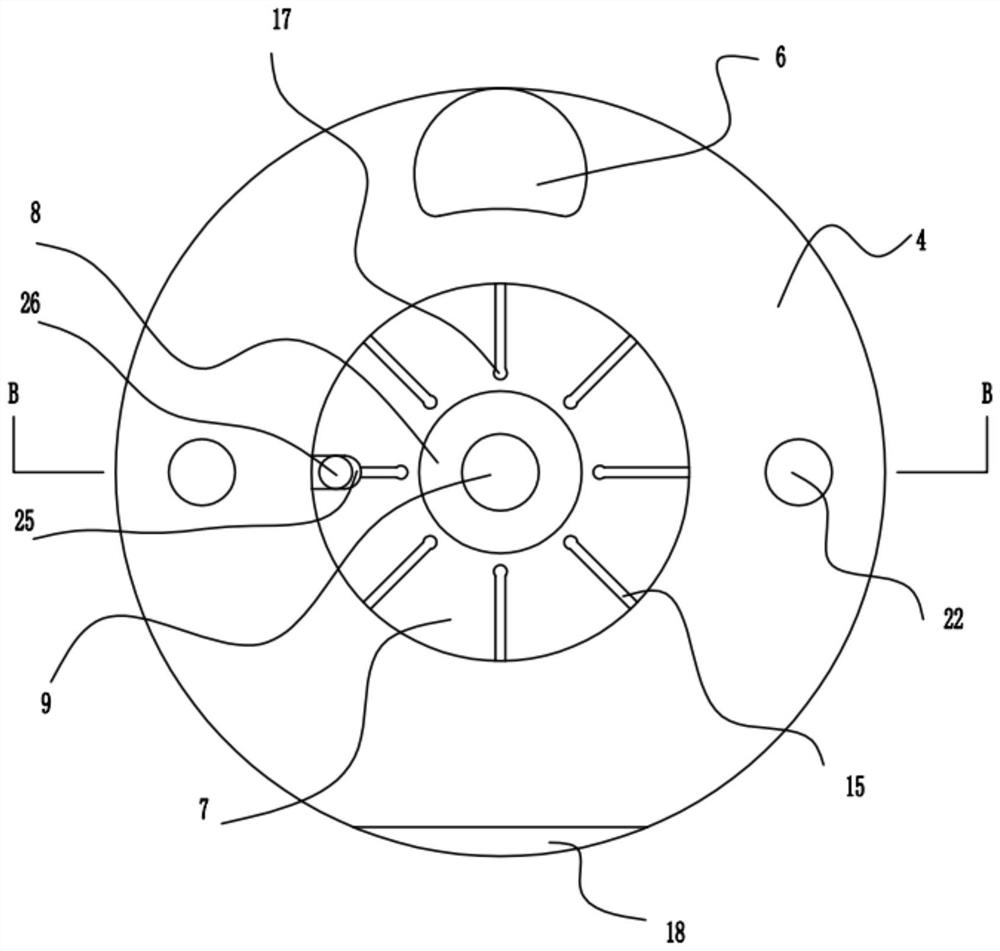

[0036] Such as image 3 , Figure 4 , Figure 5 with Image 6As shown, the present invention includes a base 4, a mandrel 5, a positioning block 6, an expansion disc 7, a briquetting block 8 and a compression bolt 9, the middle part of the base 4 is provided with a first screw hole, and the mandrel 5 and the positioning block 6 are both Fixed on the base 4, the positioning block 6 is located on one side of the mandrel 5, the upper end of the mandrel 5 is provided with a positioning boss 10, and the middle part of the mandrel 5 is provided with a first through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com