Giant magnetostrictive elliptical vibration turning device and turning method

A technology of giant magnetostrictive and giant magnetostrictive rods, applied in turning equipment, auxiliary devices, turning equipment, etc., can solve the problems of single vibration form and low output power, and achieve high energy conversion efficiency, large output power, The effect of reducing tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

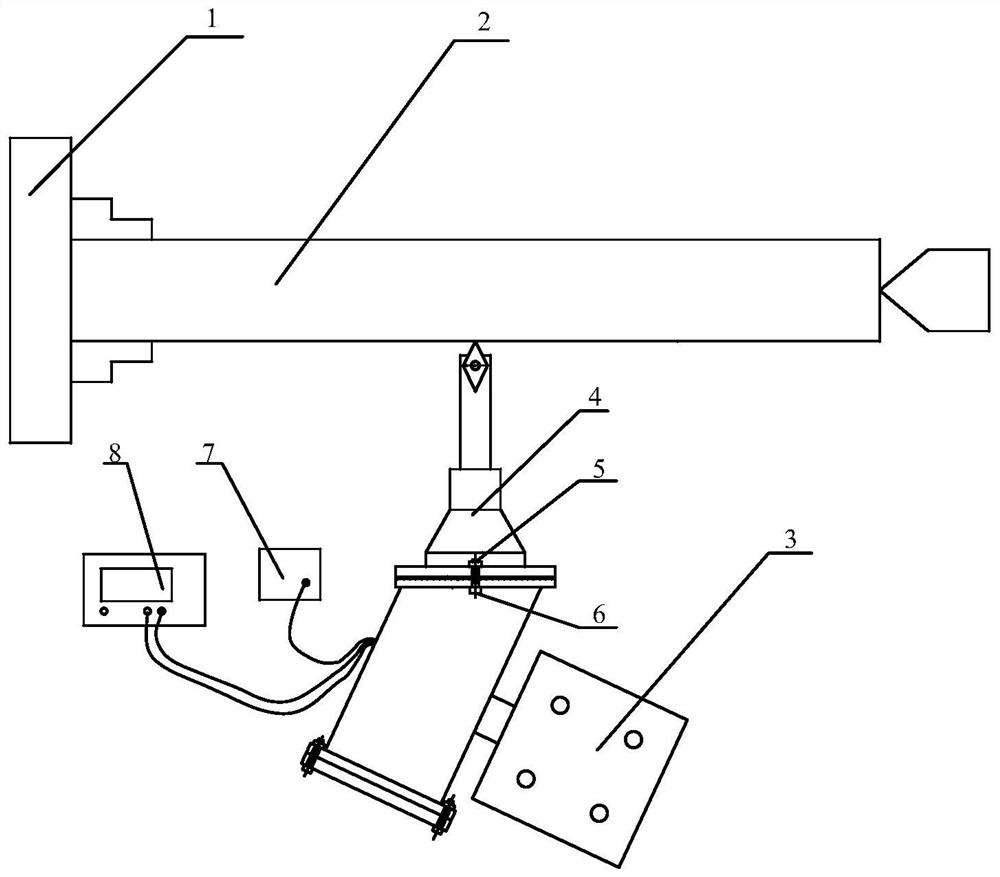

[0044] see figure 1 , the giant magnetostrictive elliptical vibration turning device provided by the present invention, the ultrasonic power supply 8 links to each other with the giant magnetostrictive transducer 4 by lead wire 20; The shell 22 of the giant magnetostrictive transducer 4 is installed on the lathe tool rest 3, It can move along the length direction and radial direction of the workpiece 2 along with the tool rest 3 of the lathe.

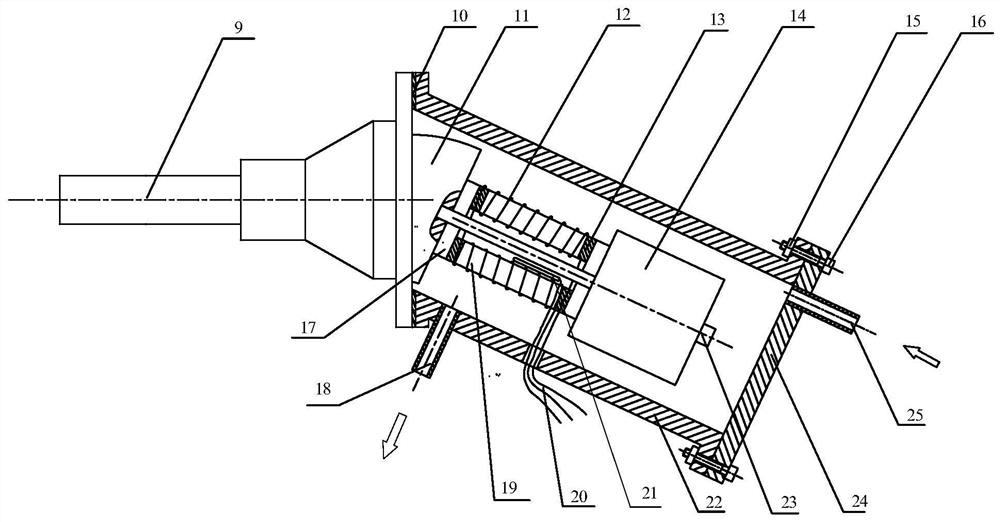

[0045] In the present embodiment, the giant magnetostrictive transducer 4 includes a casing 22, a vibration system and a cooling system, and the casing 22 is fixed on the tool rest 3; one end of the casing 22 is fixed with the horn 9 through the sealing ring 10, and the casing 22 An end cover 24 is fixed on the other end; the vibration system is placed in the casing 22 and connected to the horn 9 through the wedge block 11 ; the cooling system is placed on the casing 22 .

[0046] see figure 2 , in the present embodiment, vibration s...

Embodiment 2

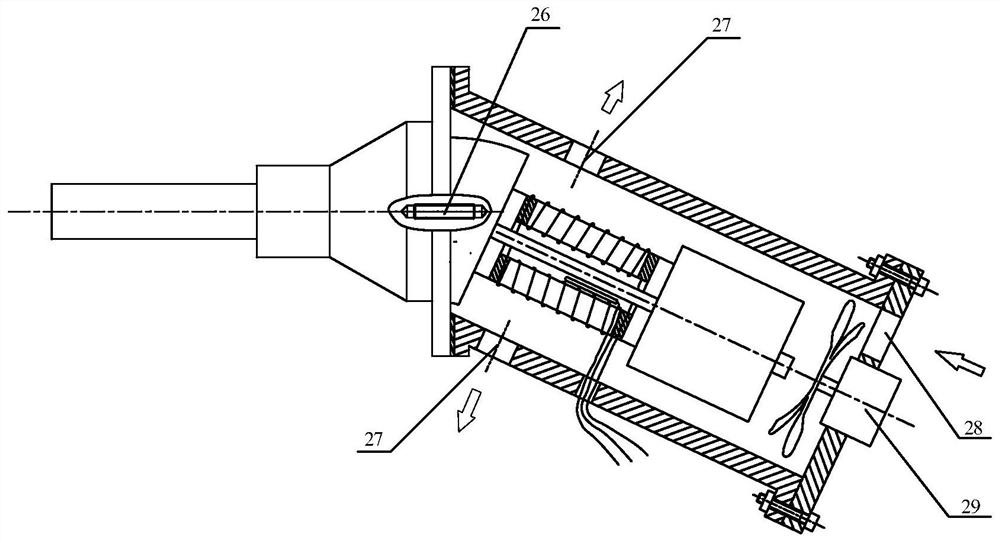

[0055] Different from Example 1, see image 3 , the cooling system is a water-cooling system, and the water-cooling system includes a water inlet pipe 25 on the end cover 24 and a water outlet pipe 18 placed on the casing 22 near the end of the horn 9 . Specifically, a water inlet is provided on the end cover 24, and a water outlet is provided on the side wall of the casing 22 near one end of the horn 9. One end of the water inlet pipe 25 passes through the water inlet and is placed in the casing 22, and one end of the water outlet pipe 18 passes through the water outlet. It communicates with the water inlet pipe 25 placed in the casing 22 . The working process of the cooling system is to control the temperature around the giant magnetostrictive rod 19 and the coil 12 through the water cooling system; Cooling water flows continuously in the pipeline in 22, and the heat generated by the giant magnetostrictive rod 19 and the coil 12 is transferred out to realize effective cooli...

Embodiment 3

[0057] In this embodiment, the material of the rear cover 14 and the horn 9 is 316 stainless steel, the diameter of the rear cover 14 is 36mm, and the length is 36.5mm; the diameter of the wedge block 11 is 49mm, the angle is 55°, and the material is 316 stainless steel The specification of the giant magnetostrictive rod 19 is 15mm×7.5mm×35mm, and the material is Terfenol-D; the material of the magnetizer 17 is ferrite; the specification of the permanent magnet 13 is 15mm×7.5mm×3mm and the material is NdFeB The flange diameter of the horn 7 is 63mm, and the length is 5mm, and the diameter of the circular table section is 49mm, and the length is 21mm, and the diameter of the large cylinder section is 25mm, and the length is 20mm, and the diameter of the small cylinder section is 15mm, and the length is 51mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com