Electric industrial brush device convenient to adjust

An industrial and electric technology, used in grinding drives, grinding/polishing safety devices, manufacturing tools, etc., can solve problems such as low use efficiency and poor adjustment effect, and achieve the effect of improving efficiency, preventing residues and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

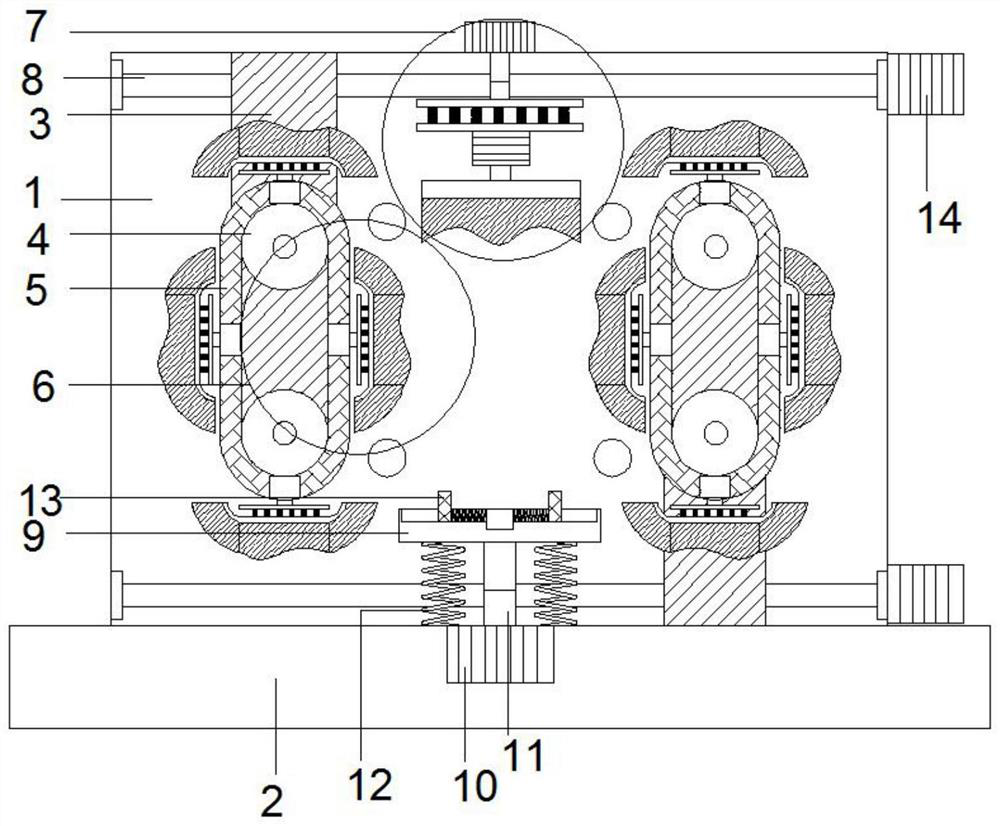

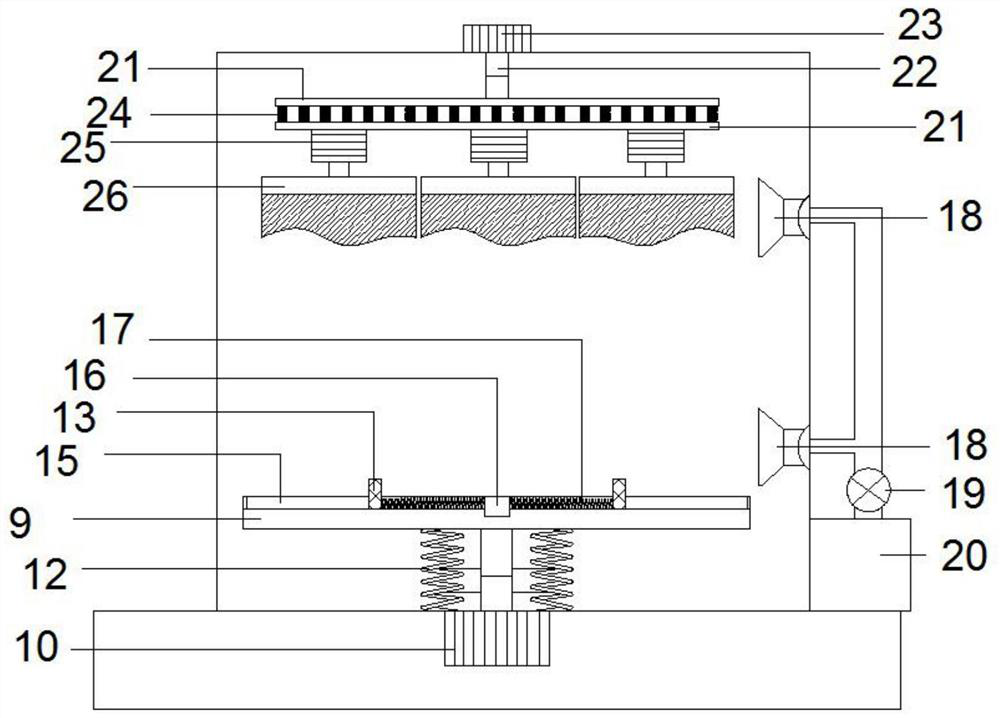

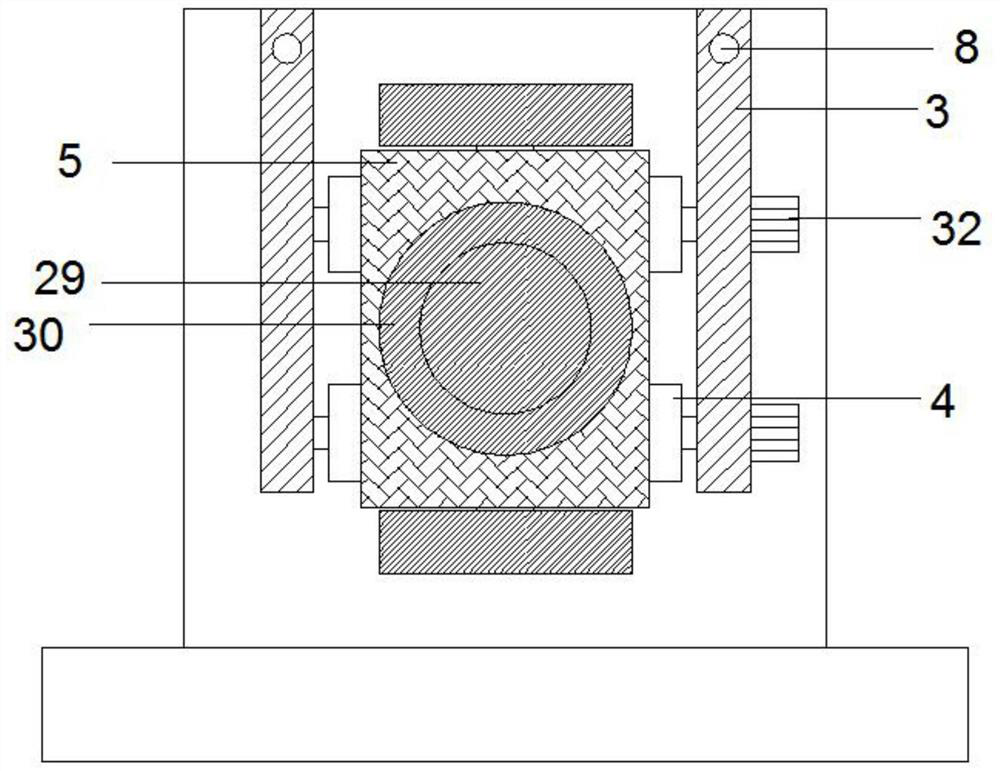

[0029] refer to Figure 1-6 , an electric industrial brush device that is easy to adjust, including a scrubbing box 1, a base 2 fixedly connected to the bottom of the scrubbing box 1, and a side cleaning mechanism 6 arranged symmetrically on the left and right sides inside the scrubbing box 1, and a set at the upper end of the scrubbing box 1 The top cleaning mechanism 7, the top cleaning mechanism 7 includes a second cylinder 23 arranged at the center of the top of the scrubbing box 1 and a second telescopic rod 22 connected to the lower end of the second cylinder 23, and the lower end of the second telescopic rod 22 extends to the scrubbing The inside of the box 1 is fixed to the connecting plate 21, and the lower end of the connecting plate 21 is fixedly connected to a plurality of second motors 25, the output shaft at the lower end of the second motor 25 is fixed to the cleaning brush 26 at the upper end, and the brushing box directly below the top cleaning mechanism 7 1 T...

Embodiment 2

[0036] Such as Figure 1-6As shown, this embodiment is basically the same as Embodiment 1. In order to facilitate the clamping of parts of different sizes, preferably, a center block 16 is arranged inside the center of the upper end of the bottom plate 9, and a center block 16 is provided on the bottom plate 9 around the center block 16. The chute 15 , the lower end of the side plate 13 is inserted into the chute 15 and is slidably connected with the bottom plate 9 , and the part of the side plate 13 inserted into the chute 15 is connected with the central block 16 through a connection spring 17 .

[0037] In order to improve the stability of the top cleaning mechanism 7, preferably, the lower end of the second telescopic rod 22 is connected to two layers of connecting plates 21, and the two layers of connecting plates 21 are connected by a plurality of second elastic members 24, and the lower end The connecting plate 21 is fixed to the second motor 25 .

[0038] Working prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com