Extrahigh-voltage inverter noise reduction device with automatic pressure relief and high-temperature fusing functions

A technology of commutation and automatic venting, which is applied to transformer/inductor parts, transformer/inductor noise damping, transformer/inductor shells, etc., which can solve the problem of automatic explosion venting, safety, failure, and failure to fall off in time and other issues, to achieve good fire extinguishing effect, good safety, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

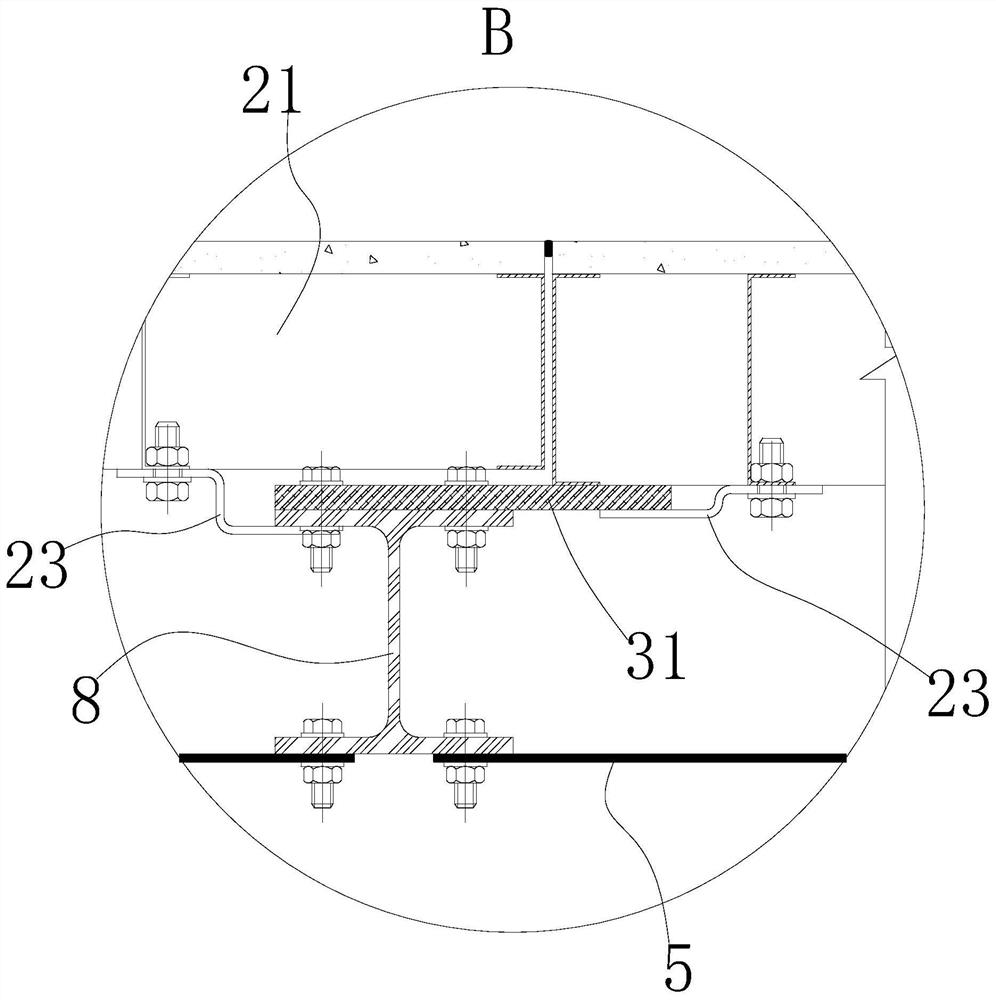

[0062] Such as figure 1 , 2 As shown, an UHV converter noise reduction device with both automatic pressure relief and high-temperature fusing functions includes a fixed part 1, a heat-melt noise reduction plate part 2, a heat-melt noise reduction plate and a heat-melt support combination part 3, a ventilator Explosion part 4, hot-melt shedding anti-drop net 5, firewall 6, fixed beam 7, and movable beam 8.

[0063] Such as figure 2 As shown, fixed beams 7 and firewalls 6 are arranged on both sides above the converter, and the fixed part 1 is erected between the fixed beams 7 and firewalls 6. For ease of understanding and description, figure 1 The viewing angle is the direction of the top view, and other directions are described based on this, such as figure 2 As shown, the fixed beam 7 is an I-beam erected along the front and rear directions.

[0064] Such as figure 2 As shown, the fixed part 1 includes a support 11 arranged on the firewall 6, a fixed metal noise-reduci...

Embodiment 2

[0119] The preparation process of the hot-melt support plate 31 in this embodiment is as follows:

[0120] The mass numbers of the components in this example are as follows: 18 parts of nylon, 5 parts of flame retardant, 3 parts of water repellent, 5 parts of antiaging agent, 2 parts of antistatic agent, and 2 parts of anti-low temperature thickener.

[0121] The antistatic agent is dithiocarbamic acid.

[0122] In step s1, weighing: according to the number of parts by mass, weigh 18 parts of nylon, 5 parts of flame retardant, 3 parts of water repellent, 5 parts of antiaging agent, 2 parts of antistatic agent, and 2 parts of anti-low temperature thickener ;

[0123] In step s2, mixing: adding the flame retardant, water repellent, anti-aging agent and antistatic agent to the mixer in sequence and mixing evenly; at the same time, heating the nylon to 275°C through the heating device and keeping it for 4 minutes to completely melt it; Then add the melted nylon and anti-low temp...

Embodiment 3

[0126] The preparation process of the hot-melt support plate 31 in this embodiment is as follows:

[0127] In this embodiment, the converter heat-melt support plate includes the following components by weight: 20 parts of nylon, 3 parts of flame retardant, 2 parts of water-repellent agent, 3 parts of anti-aging agent, 1 part of antistatic agent, anti-thickening agent at low temperature 3 doses.

[0128] The antiaging agent is aluminum oxide with a particle size of less than 3 microns, the antistatic agent is alkylsulfonic acid, and the anti-low temperature thickener is hydroxyethyl cellulose.

[0129] In step s1, weighing: according to the number of parts by mass, weigh 20 parts of nylon, 3 parts of flame retardant, 2 parts of water repellent, 3 parts of antiaging agent, 1 part of antistatic agent, and 3 parts of anti-low temperature thickener .

[0130] In step s2, mixing: adding the flame retardant, water repellent, anti-aging agent and antistatic agent to the mixer in seq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com