Moisturizing cosmetic, moisturizing mask and modified attapulgite

A technology of attapulgite and cosmetics, which is applied in the fields of moisturizing cosmetics, moisturizing masks and modified attapulgite. It can solve the problems of unsatisfactory effect and unsatisfactory moisturizing performance, and achieve excellent antibacterial performance, excellent moisturizing performance and good water retention performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

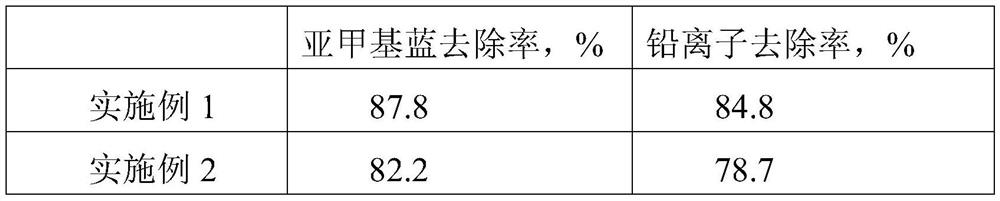

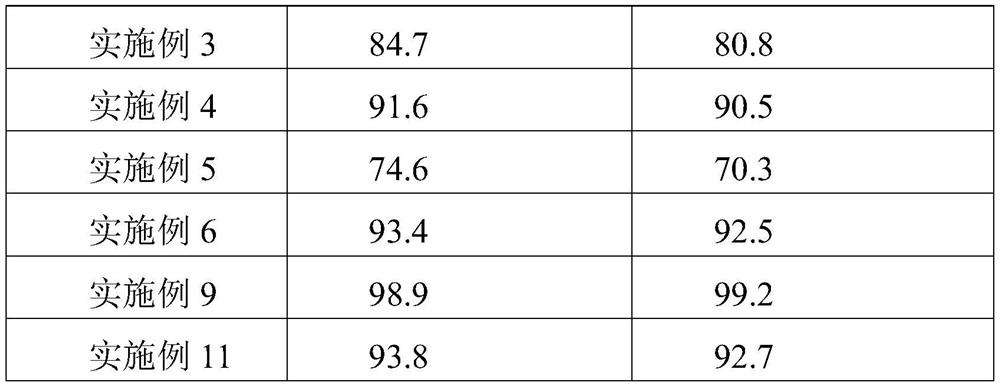

Examples

preparation example Construction

[0021] A preparation method of modified attapulgite, comprising the steps of:

[0022] (1) Mix attapulgite and sodium hexametaphosphate aqueous solution, stir at 30-70°C at 1000-2000 rpm for 20-60min, stop stirring, let stand for 60-120min, discard the lower sediment, and draw out the upper suspension, Vacuum spray dry the above suspension at 80-100°C to obtain purified attapulgite; the mass ratio of attapulgite to sodium hexametaphosphate aqueous solution is 1: (15-30); the mass concentration of sodium hexametaphosphate aqueous solution is 0.5 -3.5wt%; sodium hexametaphosphate is added to purify attapulgite, and improve adsorption capacity and water retention performance;

[0023] (2) Stir and mix 100 parts by weight of the purified attapulgite, 4-8 parts by weight of D-glucuronic acid, and 1-3 parts by weight of caprylyl glycine at 60-90°C at 800-1500 rpm for 1- After 3 hours, dry at 80-100° C. to constant weight, grind, and pass through a 100-500 mesh sieve to obtain the m...

Embodiment 1

[0033] The preparation method of modified attapulgite:

[0034] (1) Mix attapulgite and water, stir at 50°C at 1500 rpm for 40 minutes, stop stirring, and after standing for 90 minutes, the upper layer is a suspension and the lower layer is a sediment; discard the lower layer of sediment, draw out the upper layer suspension, and put the above The suspension was vacuum spray-dried at 90°C to obtain purified attapulgite; the mass ratio of the attapulgite to water was 1:20;

[0035] (2) 100 parts by weight of the purified attapulgite, 6 parts by weight of D-glucuronic acid, and 2 parts by weight of caprylyl glycine were stirred and mixed at 70°C at 1000 rpm for 2 hours, and dried at 90°C to constant weight , ground, and passed through a 300-mesh sieve to obtain the modified attapulgite.

Embodiment 2

[0037] The preparation method of modified attapulgite:

[0038] (1) Mix attapulgite and 2wt% sodium hexametaphosphate aqueous solution, stir at 50°C at 1500 rpm for 40 minutes, stop stirring, and after standing for 90 minutes, the upper layer is a suspension and the lower layer is a sediment; discard the lower layer of sediment, extract The upper layer suspension is vacuum spray-dried at 90°C to obtain purified attapulgite; the mass ratio of the attapulgite to the 2wt% sodium hexametaphosphate aqueous solution is 1:20;

[0039] (2) 100 parts by weight of the purified attapulgite and 6 parts by weight of D-glucuronic acid were stirred and mixed at 70°C at 1000 rpm for 2 hours, dried at 90°C to constant weight, ground, and passed through a 300-mesh sieve , to obtain the modified attapulgite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com