Control valve for variable displacement compressor

A technology for compressors and control valves, which is applied to the field of control valves for variable-capacity compressors, can solve the problems of enlarged valve body, complicated structure, and reduced control accuracy, so as to suppress tight fit and reduce contact. Area, the effect of ensuring surface accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

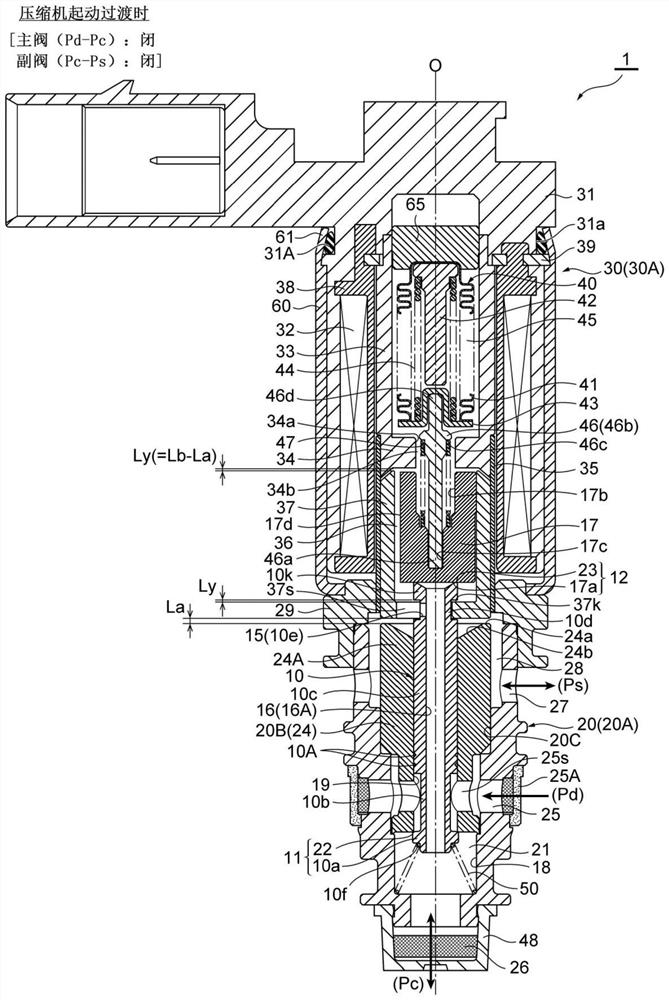

[0040] Below, while referring to the attached Figure 1 Embodiments of the present invention will be described.

[0041] Figure 1 ~ Figure 4 It is a longitudinal sectional view showing one embodiment of the control valve for a variable displacement compressor of the present invention, figure 1 Indicates the state of main valve: fully open and auxiliary valve: closed (during normal control (when energized and disconnected)), figure 2 Indicates the state of main valve: open and auxiliary valve: closed (during normal control (when energized and turned on)), image 3 Indicates the state of main valve: closed and auxiliary valve: closed (when the compressor starts transition), Figure 4 Indicates the state of main valve: closed and auxiliary valve: open (when the compressor is started). in addition, figure 2 expressed in (relative to figure 1 ) is a state in which the valve opening of the valve port 22 (from the fully open state) is adjusted (valve opening: small state) by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com