An integrated on-site hydrolysis hydrogen production and hydrogen fuel cell power generation device and method

A fuel cell, hydrogen production technology by hydrolysis, applied in fuel cells, fuel cell additives, electrochemical generators, etc., can solve large energy loss, time consumption and investment costs, difficult hydrogen fuel cells, and the existence of harmful by-products To achieve the effect of convenient fuel replacement, low cost and stable hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in further detail below in conjunction with accompanying drawing:

[0044] The core of the present invention is the integrated design of the on-site hydrolysis hydrogen production device and the hydrogen fuel cell power generation device. The hydrogen fuel cell power generation device is used as a part of the shell of the on-site hydrolysis hydrogen production device, and the hydrogen produced by the on-site hydrolysis hydrogen production device It is supplied to hydrogen fuel cell power generation devices.

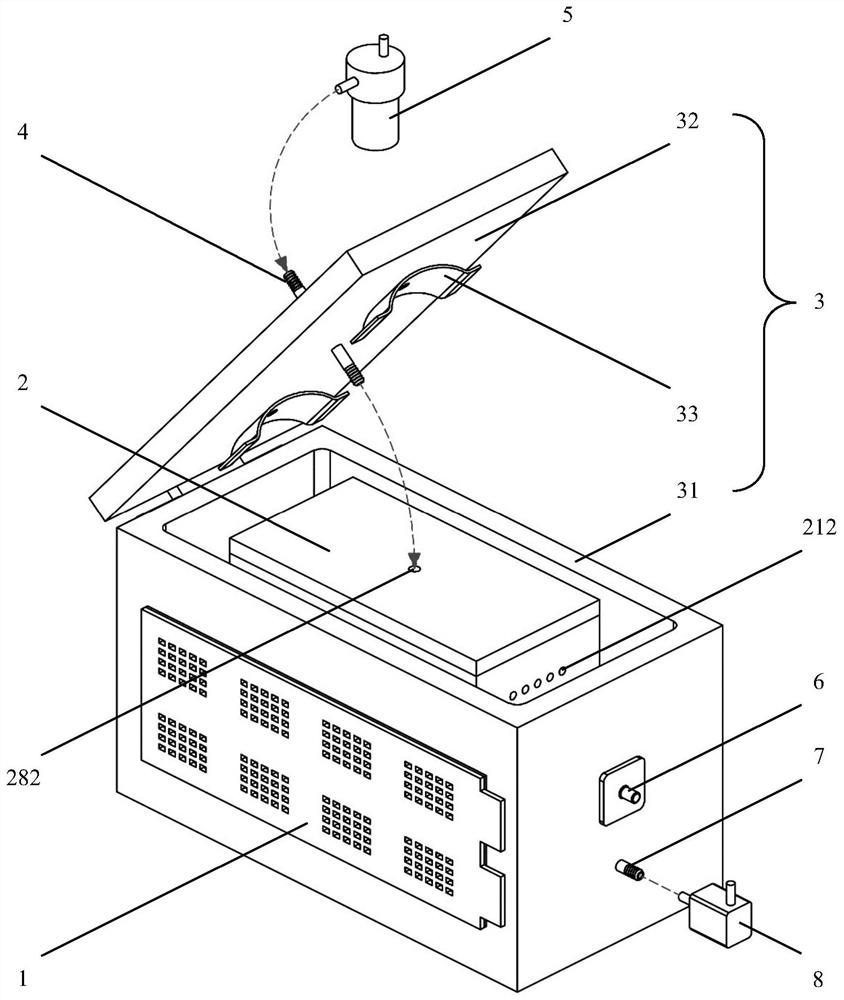

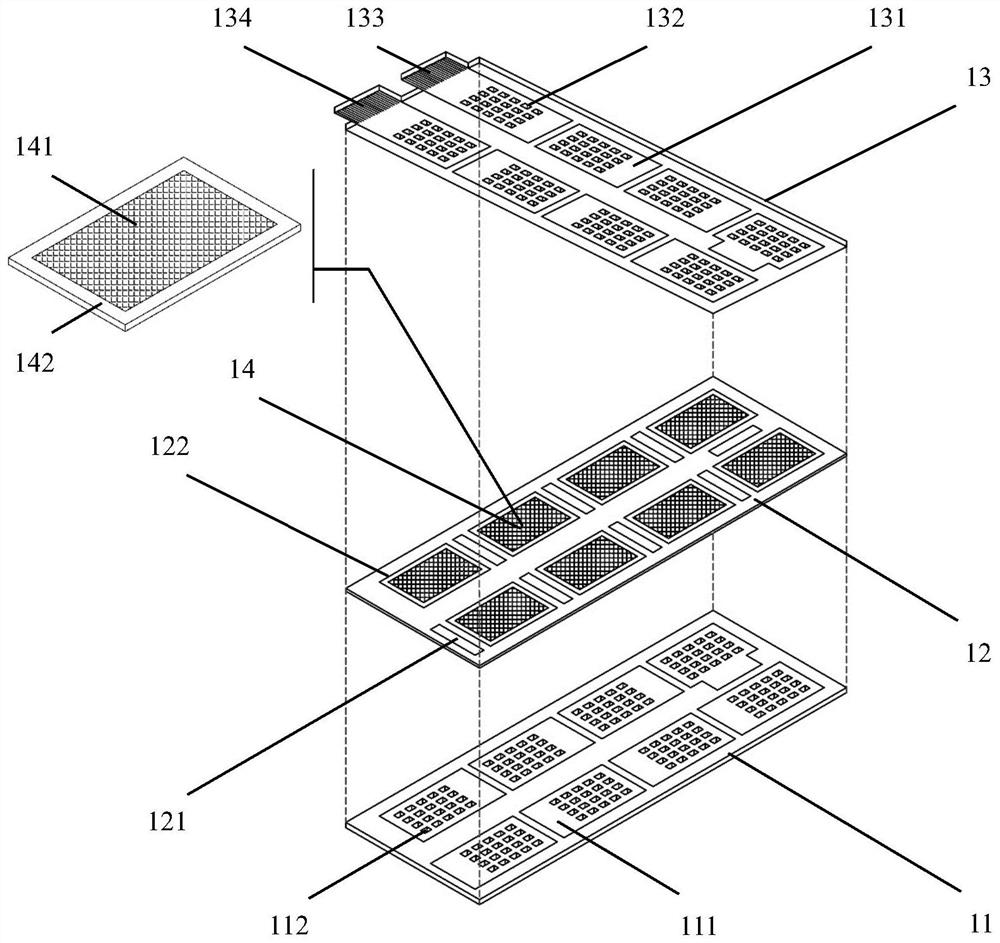

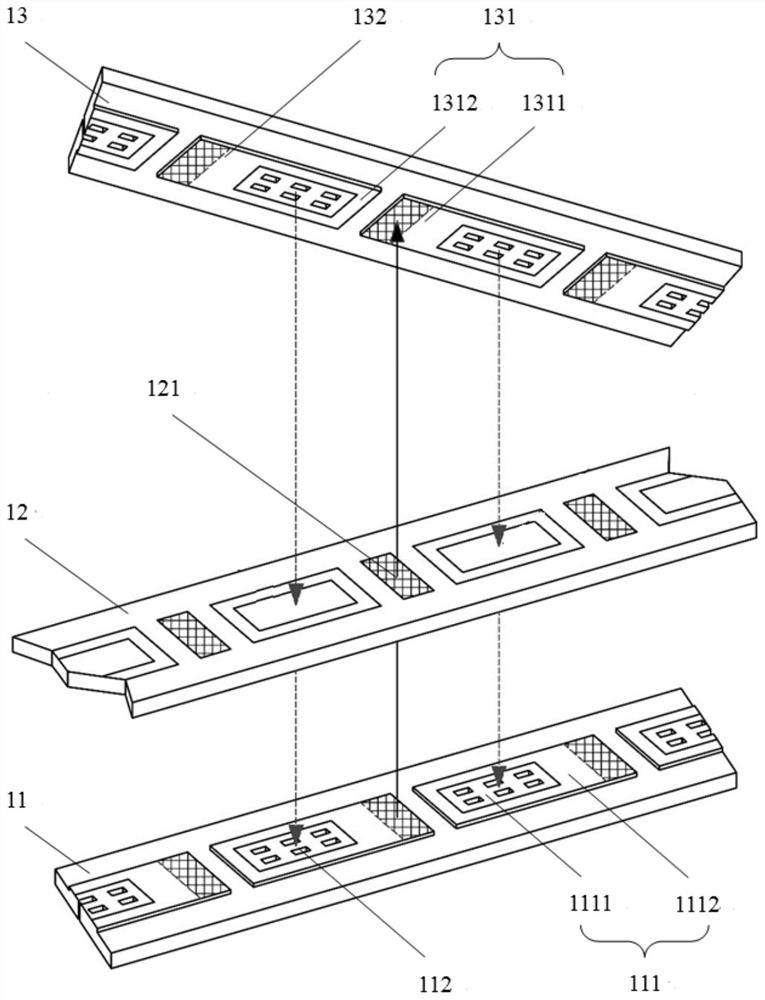

[0045] Specifically, refer to figure 1 , the integrated on-site hydrolysis hydrogen production and hydrogen fuel cell power generation device described in the present invention includes a fuel cell assembly 1, a fuel box 2, a hydrogen production box 3, a water inlet joint 4, a water pump 5 and an electromagnetic safety valve 8; a hydrogen production box 3 A cavity cover is provided at the opening of the top of the tank, the fuel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com