Radiator for power device and power device

A technology of power devices and heat sinks, which is applied in semiconductor/solid-state device components, electric solid-state devices, semiconductor devices, etc., and can solve problems such as failure of power devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

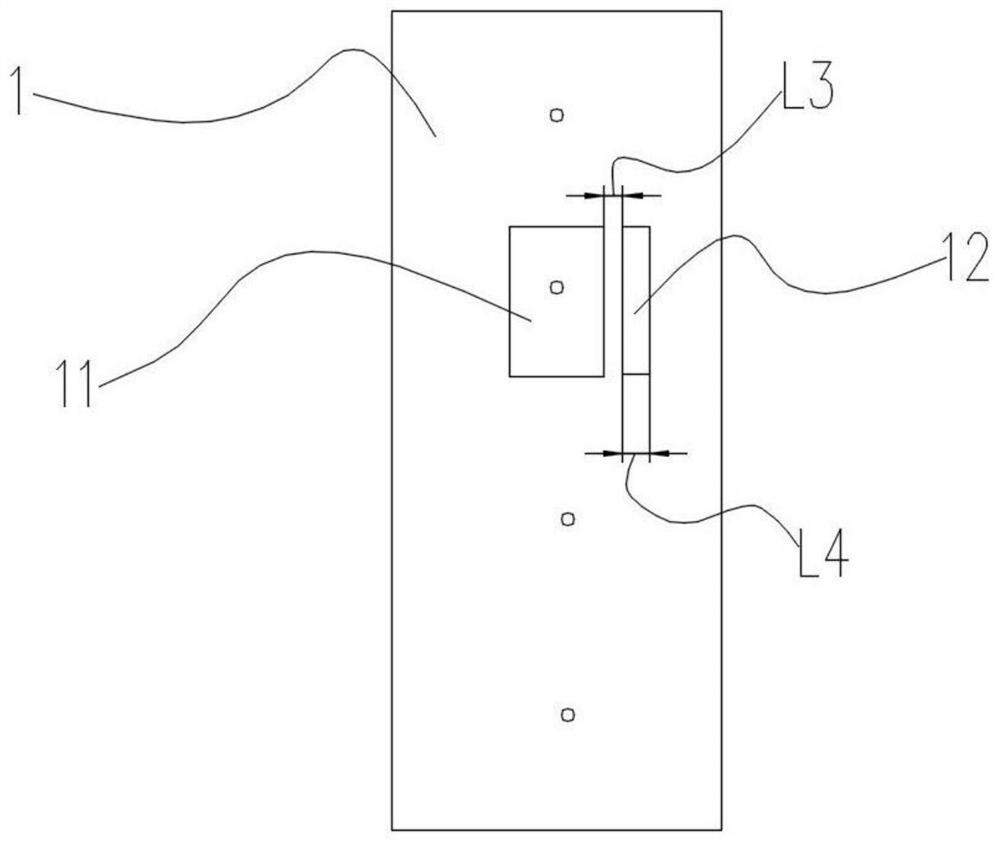

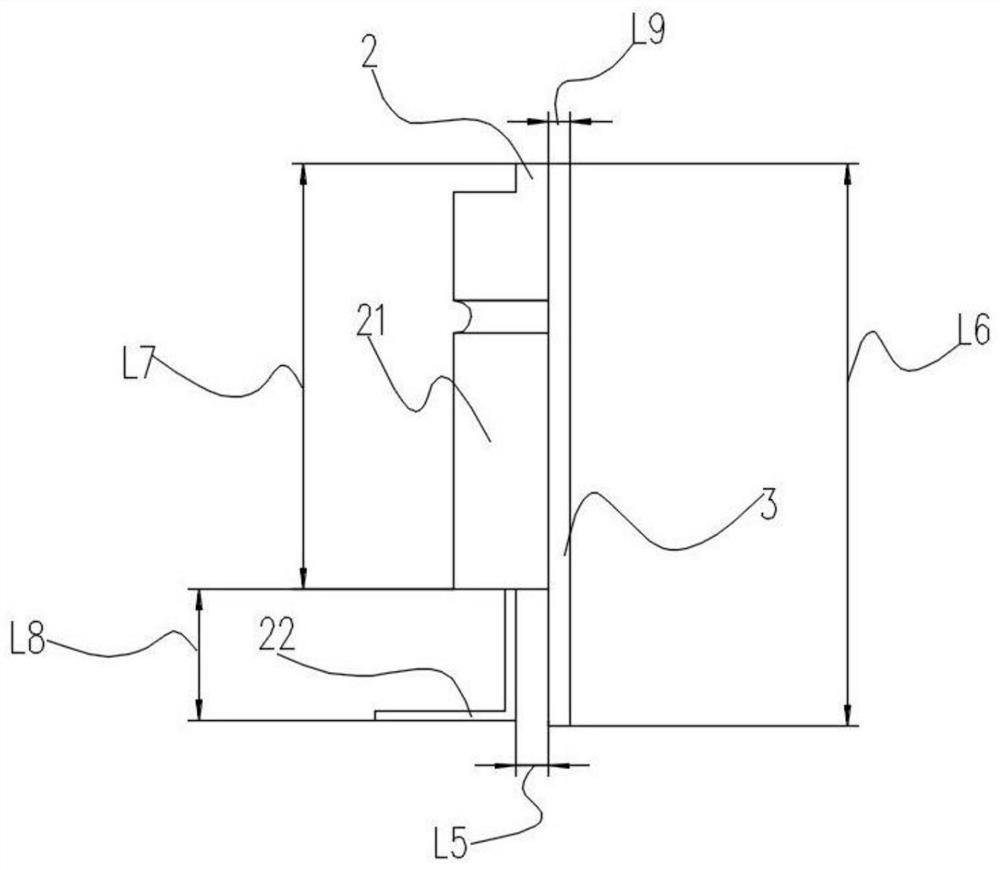

[0029] Such as Figure 1-2 As shown, the present embodiment provides a power device, the heat sink 1 combined with the power device 2 performs heat dissipation, wherein, the heat sink 1 is formed with a raised structure 11 on the contact surface with the power device 2, even if the heat sink 1 The heat dissipation surface protrudes upwards to form a mounting area for the power device 2 , and a power device mounting surface for mounting the power device 2 is formed on the mounting area formed by the raised structure 11 . Specifically, the non-metallic mounting surface formed on the upper surface of the power device 2, when the power device 2 is assembled to the radiator 1, the non-metallic mounting surface of the power device 2 and the power device mounting surface on the raised structure 11 are matched to complete the installation, wherein , the range of the height L1 of the raised structure 11 is 1.5mm-2.5mm, further, the range of the height L1 of the raised structure 11 is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com