Automatic peeling, cutting and recycling device adapting to cable and wire deformation

A recovery device and electric wire technology, applied in the field of automatic peeling and cutting recovery devices, can solve the problems affecting the recovery of wire cores, adjusting the height of cutting knives, excessive cutting, etc., and achieve the effects of improving recovery efficiency, ensuring cutting depth, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

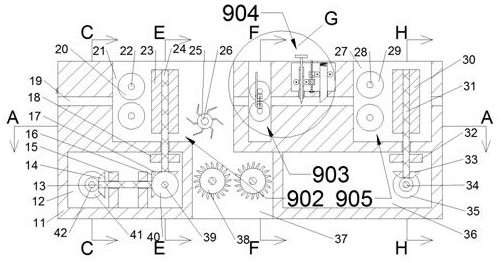

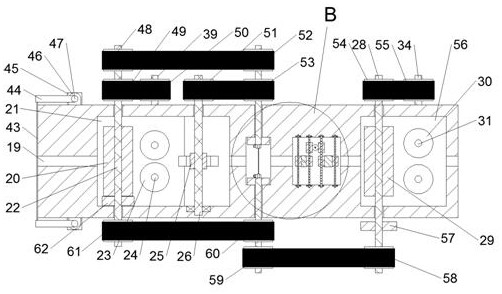

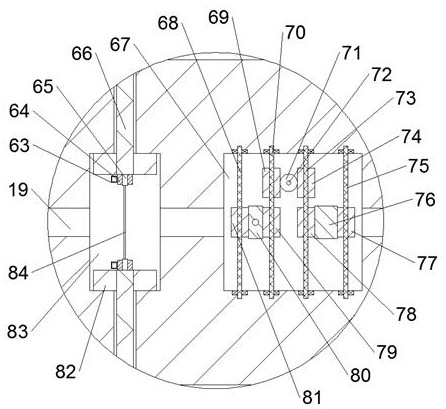

[0023] Combine below Figure 1-Figure 9 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent.

[0024] The present invention relates to an automatic peeling, cutting and recovery device adapted to the deformation of cables and wires, which is mainly used in the process of automatic peeling, cutting and recycling of cables and wires. The following will further describe the invention in conjunction with the accompanying drawings of the present invention:

[0025] An automatic peeling and cutting recovery device adapted to the deformation of cables and wires according to the present invention includes a box body 11, and the left and right sides of the box body 11 are provided with transmission holes 19, and the box body 11 is provided with a transmission cavity 12. The trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com