Multi-core flame-retardant power cable

A kind of power cable and combined technology, applied in the field of multi-core resistance power cables, can solve the problems of inconvenient stripping and construction, high cost, poor heat dissipation effect, etc., and achieve excellent heat dissipation effect, small diameter and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

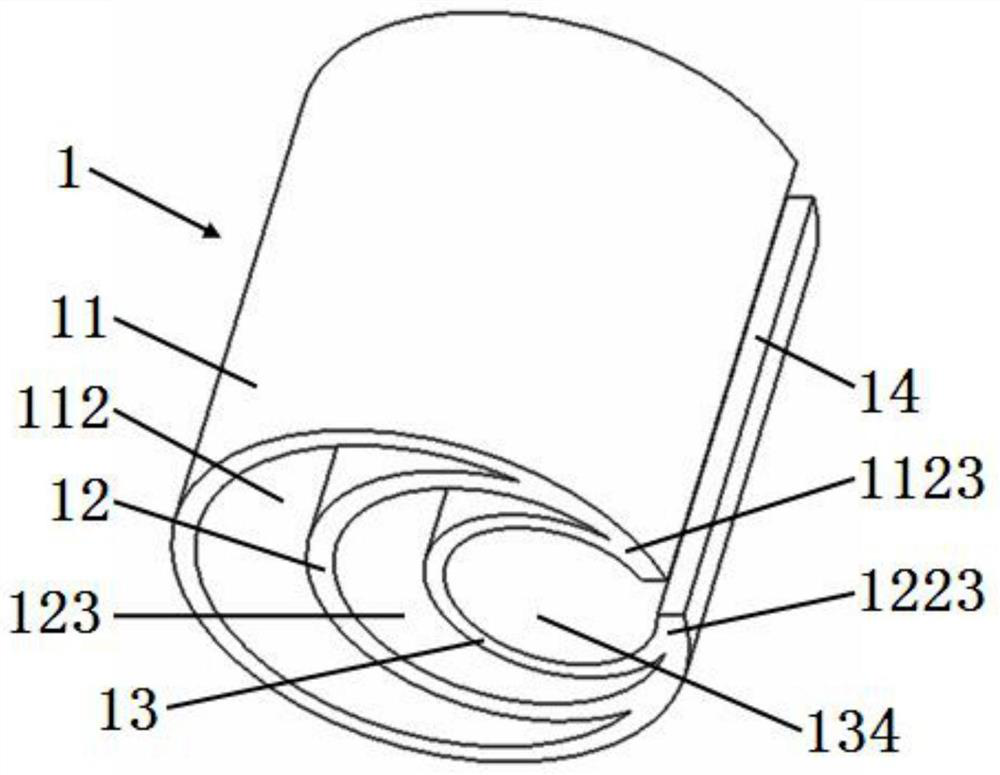

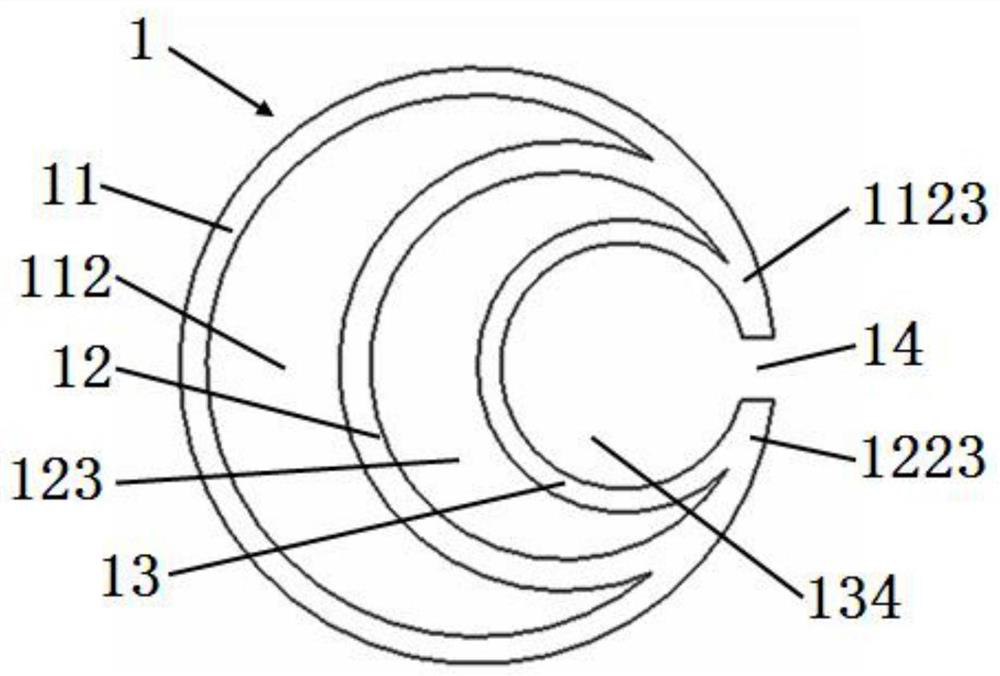

[0041] please see Figure 1 to Figure 4 , a multi-core resistance power cable, with a first power transmission unit 21, a second power transmission unit 23, a third power transmission unit 34, and an insulating component 1, characterized in that the insulating component 1 is composed of a first insulator 11, a second insulator 12 , the third insulator 13, one end of the first insulator 11, the second insulator 12, and the third insulator 13 are connected together to form an upper joint 1123 on the insulator, and the first insulator 11, the second insulator 12, and the third insulator 13 are three The other end of the insulator is connected together to form the lower joint part 1223 of the insulator, an opening 14 is formed between the upper joint part 1123 of the insulator and the lower joint part 1223 of the insulator, and the first insulator 11, the second insulator 12, and the third insulator 13 are all round. A part of the ring cylinder, the first cavity 112 is formed betw...

Embodiment 2

[0045] please see Figure 5 to Figure 10 , a multi-core resistance power cable, which has a first power transmission unit 21, a second power transmission unit 23, a third power transmission unit 34, an insulating component 1, and an engaging component 3, wherein the insulating component 1 is composed of a first An insulator 11, a second insulator 12, and a third insulator 13 are formed. One end of the first insulator 11, the second insulator 12, and the third insulator 13 are connected together to form an upper joint 1123 on the insulator. The first insulator 11 and the second insulator 12. The other ends of the third insulator 13 are connected together to form the lower joint part 1223 of the insulator, and an opening 14 is formed between the upper joint part 1123 of the insulator and the lower joint part 1223 of the insulator. The first insulator 11, the second insulator 12, the third insulator The three insulators 13 are all part of the ring cylinder, the first cavity 112 i...

Embodiment 3

[0050] please see Figure 11 and Figure 12 , and refer to Figure 5 to Figure 10 , a multi-core resistance power cable, which has a first power transmission unit 21, a second power transmission unit 23, a third power transmission unit 34, an insulating part 1, and an engaging part 3, wherein the insulating part 1 is composed of a first An insulator 11, a second insulator 12, and a third insulator 13 are formed. One end of the first insulator 11, the second insulator 12, and the third insulator 13 are connected together to form an upper joint 1123 on the insulator. The first insulator 11 and the second insulator 12. The other ends of the third insulator 13 are connected together to form the lower joint part 1223 of the insulator, and an opening 14 is formed between the upper joint part 1123 of the insulator and the lower joint part 1223 of the insulator. The first insulator 11, the second insulator 12, the third insulator The three insulators 13 are all part of the ring cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com