Galvanizing production line product quality monitoring method, device and system

A monitoring system and product quality technology, which is applied in the direction of manufacturing computing systems, instruments, data processing applications, etc., can solve the problems of reduction and waste of agreed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 of the present invention provides a monitoring method for product quality of a galvanizing production line, which is applied to a monitoring system of a galvanizing production line. The monitoring device of the inlet meter and the control device connected to the monitoring device.

[0040] The server version in the existing monitoring system is low, the memory is small, and the equipment is old. Adding a new program process requires adding a lot of code, which easily increases the memory burden and affects the normal production of the production line. The method for monitoring product quality of a galvanizing production line provided by the invention can be applied to an existing monitoring system.

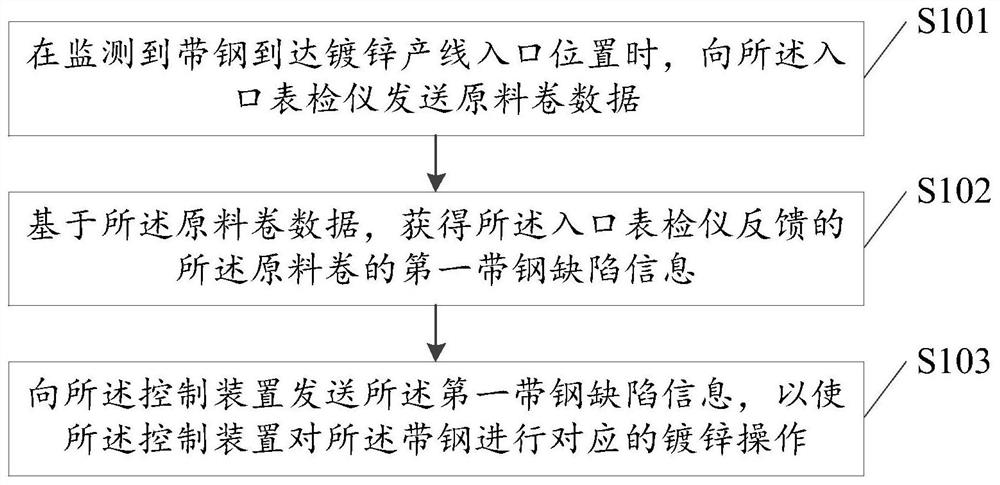

[0041] The monitoring device in the monitoring system of the galvanizing production line is used as the execution subject, such as figure 1 As shown, the monitoring method includes: S101, when it is detected that the strip arrives at the entrance of the galvan...

Embodiment 2

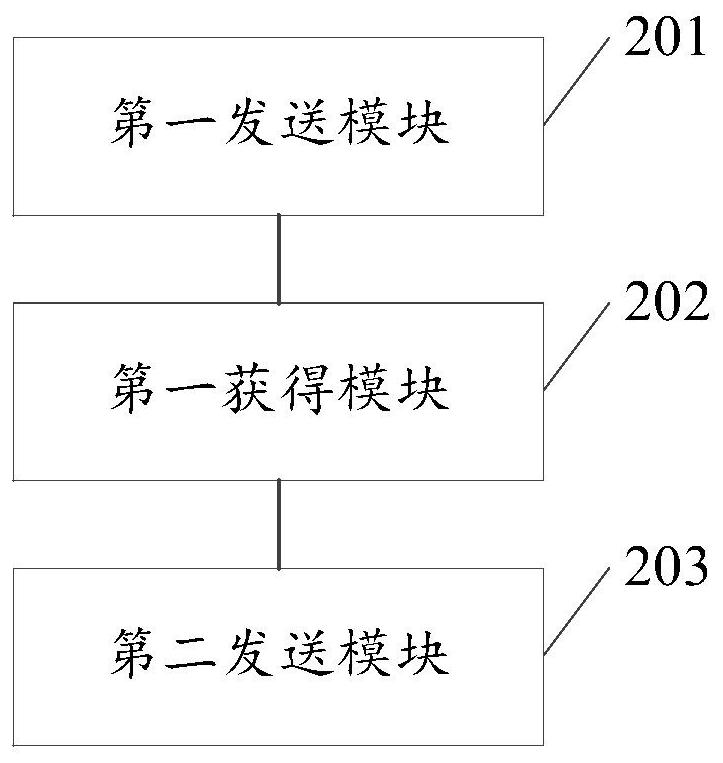

[0066] Based on the same inventive concept, the present invention provides a monitoring device for the product quality of a galvanizing production line, such as figure 2 shown, including:

[0067] The first sending module 201 is used to send raw material volume data to the entrance meter inspection instrument when the strip steel arrives at the entrance position of the galvanizing production line;

[0068] The first obtaining module 202 is configured to obtain the first steel strip defect information of the raw material coil fed back by the entrance meter inspection instrument based on the raw material coil data;

[0069] The second sending module 203 is configured to send the first strip defect information to the control device, so that the control device performs a corresponding galvanizing operation on the strip.

[0070] In an optional embodiment, the monitoring device for the product quality of the galvanizing production line also includes:

[0071] The third sending m...

Embodiment 3

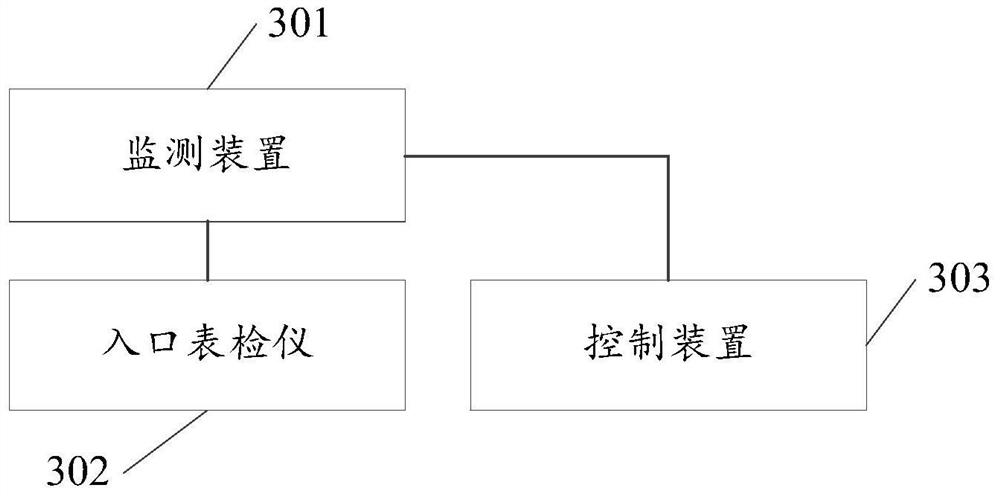

[0084] Based on the same inventive concept, the present invention also provides a monitoring system for the product quality of the galvanized production line, such as image 3 shown, including:

[0085] The monitoring device 301 is used to send raw material volume data to the entrance meter 302 when the strip steel arrives at the entrance position of the galvanizing production line;

[0086] The entrance meter inspection instrument 302 located at the entrance of the galvanizing production line is used to receive the raw material volume data sent by the monitoring device 301, and generate first strip defect information based on the raw material volume data, and send the sending the first steel strip defect information to the monitoring device 301;

[0087] The control device 303 is configured to receive the first strip defect information sent by the monitoring device 301, and perform a corresponding galvanizing operation on the strip based on the first strip defect information...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com