System and method for monitoring scaling rate and deposition rate of circulating cooling water

A technology of circulating cooling water and deposition rate, which is applied in the field of deposition rate monitoring system and circulating cooling water scaling rate, and can solve problems such as inability to distinguish and completely simulate the state of circulating cooling water system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The invention will be further described below with reference to the drawings and specific implementation examples.

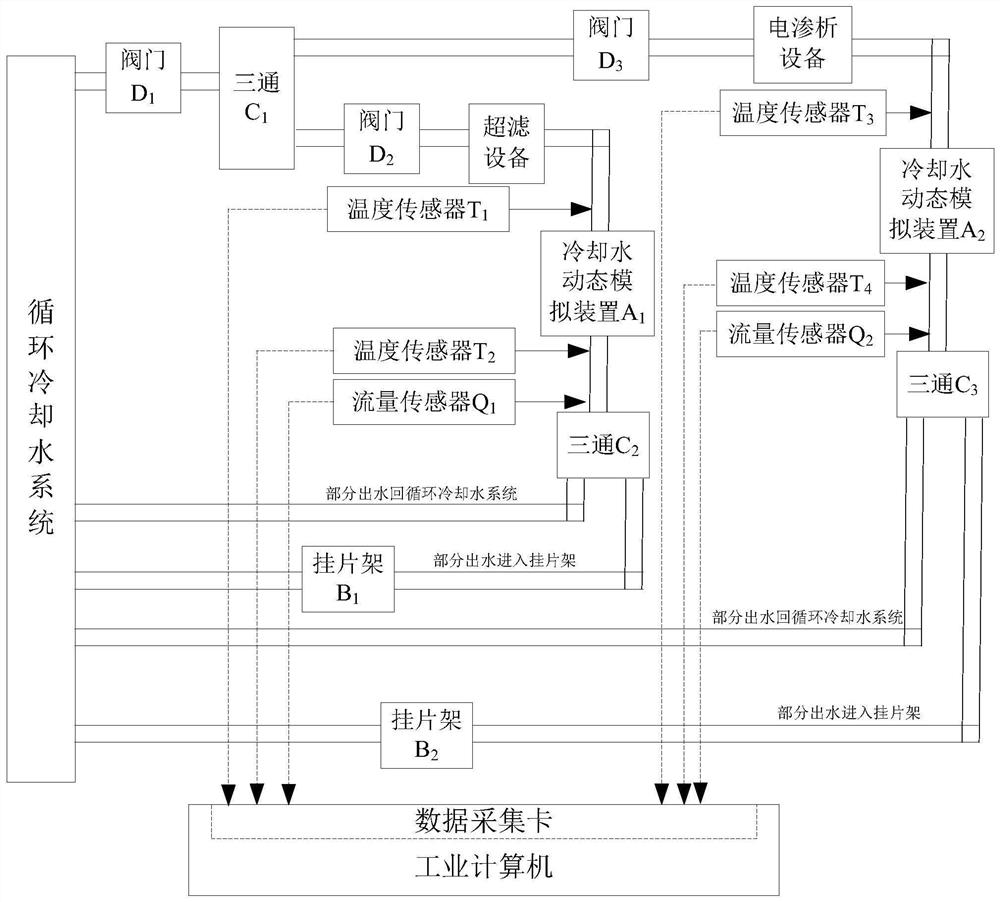

[0066] Such as figure 1 As shown, a circulating cooling water fouling rate and deposition rate monitoring system includes a circulating cooling water system, ultrafiltration equipment, electrodialysis equipment, and cooling water dynamic simulation device A 1 , Cooling water dynamic simulation device A 2 , Hanger B 1 , Hanger B 2 , And connected by pipelines into two loop systems, namely the loop system System1 where the ultrafiltration equipment is located and the loop system System2 where the electrodialysis equipment is located; it also includes a temperature sensor T 1 , Temperature sensor T 2 , Temperature sensor T 3 , Temperature sensor T 4 , Flow sensor Q 1 , Flow sensor Q 2 , Data acquisition card, industrial computer;

[0067] The loop system System1 where the ultrafiltration equipment is located is specifically expressed as: Tee C is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com