Flexible strain sensor based on MXene material and preparation and application thereof

A strain sensor and sensor technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of lack of packaging layer in sensor structure design, great influence on sensor performance, and affect sensing performance, etc., to achieve human Machine interaction function, simple preparation method, and the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

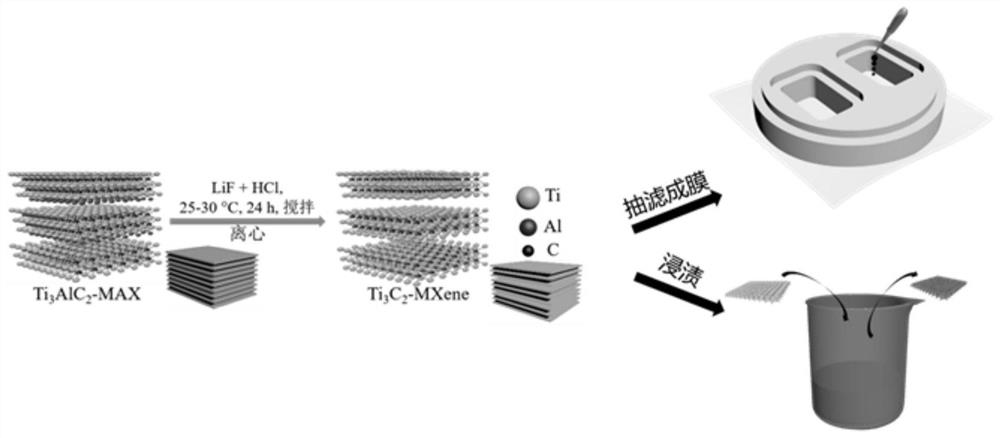

[0043] Wet Chemical Etching of Parent Ti 3 AlC 2 -MAX powder, preparation of Ti 3 C 2 -MXene membrane, figure 1is its preparation flow chart, that is, it is prepared by selectively etching away the A atoms in the MAX phase (M represents a transition metal, X represents carbon or nitrogen, and A represents the III or IV main group element). Specific preparation method: place the polytetrafluoroethylene bottle on a magnetic stirrer, first add 12mL concentrated HCl (9M, hydrochloric acid concentration 36%-38%) and 1mL ultrapure water, at a speed of 3500r / min, the temperature is 25- Slowly add 1g LiF (lithium fluoride) at 35°C, stir until dissolved, then slowly add 1g Ti 3 AlC 2 -MAX powder; secondly, keep the temperature at 25-30°C for etching for 24 hours; finally pour it into a centrifuge tube, wash the etching solution by centrifugation at 3500r / min, centrifuge for 5 minutes each time, and repeatedly centrifuge and wash until pH ≥ 6 to obtain Ti 3 C 2 - Colloidal solut...

Embodiment 2

[0048] Wet Chemical Etching of Parent Ti 3 AlC 2 -MAX powder, preparation of Ti 3 C 2 -MXene membrane, figure 1 A flowchart is prepared for it, that is, it is prepared by selectively etching away A atoms in the MAX phase (M represents a transition metal, X represents carbon or nitrogen, and A represents a group III or IV main group element). Specific preparation method: place the polytetrafluoroethylene bottle on a magnetic stirrer, first add 30mL concentrated HCl (9M, hydrochloric acid concentration 36%-38%) and 2mL ultrapure water, at a speed of 3500r / min, the temperature is 25- Slowly add 2g LiF (lithium fluoride) at 30°C, stir until dissolved, then slowly add 2g Ti 3 AlC 2 -MAX powder; secondly, keep the temperature at 25-35°C for etching for 48 hours; finally pour it into a centrifuge tube, wash the etching solution by centrifugation at 3500r / min, centrifuge for 5 minutes each time, and repeatedly centrifuge and wash until pH ≥ 6 to obtain Ti 3 C 2 - Colloidal sol...

Embodiment 3

[0053] Wet Chemical Etching of Parent Ti 3 AlC 2 -MAX powder to prepare flexible fabric sensors, figure 1 is its preparation flow chart, that is, it is prepared by selectively etching away the A atoms in the MAX phase (M represents a transition metal, X represents carbon or nitrogen, and A represents the III or IV main group element). Specific preparation method: place the polytetrafluoroethylene bottle on a magnetic stirrer, first add 12mL concentrated HCl (9M, hydrochloric acid concentration 36%-38%) and 1mL ultrapure water, at a speed of 3500r / min, the temperature is 25- Slowly add 1g LiF (lithium fluoride) at 35°C, stir until dissolved, then slowly add 1g Ti 3 AlC 2 -MAX powder; secondly, keep the temperature at 25-30°C for etching for 24 hours; finally pour it into a centrifuge tube, wash the etching solution by centrifugation at 3500r / min, centrifuge for 5 minutes each time, repeatedly centrifuge and wash until pH ≥ 6, add ultra- After pure water and centrifugation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com